Customizable Battery Pack Production Machine OEM Power Pack Assembly

High quality Customizable Battery Pack Production Machine OEM Power Pack Assembly For Cylindrical Lithium Iron Phosphate Batteries from China, China''s leading oem power pack

Design for Assembly and Disassembly of Battery Packs

Aug 23, 2019 · LIB batteries are common in EVs and one type that is often applied is the Lithium Iron Phosphate (LFP). This chemistry utilises phosphate as the negative terminal and

How to Assemble LiFePO4 Cells into Battery Modules Using

Nov 18, 2024 · LiFePO4 (Lithium Iron Phosphate) cell pressing to a module refers to the process of assembling individual LiFePO4 cells into a module, which is a key step in the production of

Process steps of lithium iron phosphate battery assembly

The process steps of lithium iron phosphate battery assembly technology mainly include the following aspects: Select appropriate battery cells, ensure that the battery cell type, voltage,

Automatic New Energy Vehicle Lithium Iron Phosphate Battery

Heat Press:Thermal Press Pack the Battery Pack to Complete the Connection and Protection Circuit Installation,Make the battery pack structure more compact,Enhance overall stability.

The Manufacturing Process Behind Lithium Iron Phosphate Battery

Nov 13, 2024 · The core of the lithium iron phosphate battery cell manufacturing process lies in the assembly and formation of the cell components. The electrode sheets, along with a

L822 battery.Lithium iron phosphate battery assembly

Dec 6, 2024 · In the lithium iron phosphate battery assembly production process, pole piece production is the foundation and battery cell production is the core. Battery assembly is related

Assembly process of lithium iron phosphate battery

May 5, 2021 · Assembly process of lithium iron phosphate battery. Choose the right battery. The battery type, voltage, and internal resistance must be matched. Please balance the battery

LiFePO4 Cells Pack Assembly Line

Sep 13, 2024 · ALiFePO4 cells pack assembly line automates the process of assembling individual LiFePO4 cells into battery packs, ensuring consistency, precision, and efficiency.

DIY LiFePO4 Battery Pack: Step-by-Step Guide (2025 Update

Apr 18, 2025 · How to Build a LiFePO4 Battery Pack: DIY Guide with Expert Tips (2025) Why Build a LiFePO4 Battery Pack? LiFePO4 (Lithium Iron Phosphate) batteries dominate

Automatic New Energy Vehicle Lithium Iron Phosphate Battery

Internal Resistance Tester:Measuring the Internal Resistance of the Cell by Ac Signals at Specific Frequencies,Select batteries with similar internal resistance,Ensure Consistent Battery Pack

Custom Battery Packs & Assemblies | Power Solutions

For over 57 years, Custom Power has designed, developed, and manufactured high-quality, reliable, custom battery packs. We provide battery pack assemblies in all chemistries,

KNOWLEDGE PAPER ON LITHIUM-ION BATTERY

Jan 22, 2024 · Shapes of lithium-ion cell Types of Li-ion cells Nomenclature of lithium-ion cell/battery Battery-pack assembly line Cell testing machine Module testing machine Pack

Assembly Line Improvements for Lithium Iron Phosphate Battery

Aug 8, 2025 · The assembly of Lithium Iron Phosphate (LFP) batteries presents several significant challenges that impact production efficiency, quality, and cost-effectiveness. One of the

EV Lithium Battery Soldering Machine Production Battery Line Lithium

Jul 27, 2025 · EV Lithium Battery Soldering Machine Production Battery Line Lithium Iron Phosphate Battery Production Machine . US$1,200,000.00 - 1,400,000.00. 1 Sets(MOQ) .

Stellantis and CATL to Invest Up to €4.1 Billion in

Dec 10, 2024 · Stellantis is employing a dual-chemistry approach – lithium-ion nickel manganese cobalt (NMC) and lithium iron phosphate (LFP) – to serve

Update Information

- Assembly 24V lithium iron phosphate battery pack

- Cook Islands lithium iron phosphate battery pack

- 144v lithium iron phosphate battery pack

- 41kw lithium iron phosphate battery pack

- 12V 3-channel 4-channel lithium iron phosphate battery pack

- Rechargeable lithium iron phosphate battery pack

- How much is the lithium iron phosphate battery pack

- 500ha lithium iron phosphate battery pack price

- Inverter 12v lithium iron phosphate battery assembly

- Which lithium iron phosphate battery pack in Chad decays faster

- 4 strings of 12v50a lithium iron phosphate battery pack

- N Djamena lithium iron phosphate battery pack

- Argentina Cordoba cylindrical lithium iron phosphate battery

Solar Storage Container Market Growth

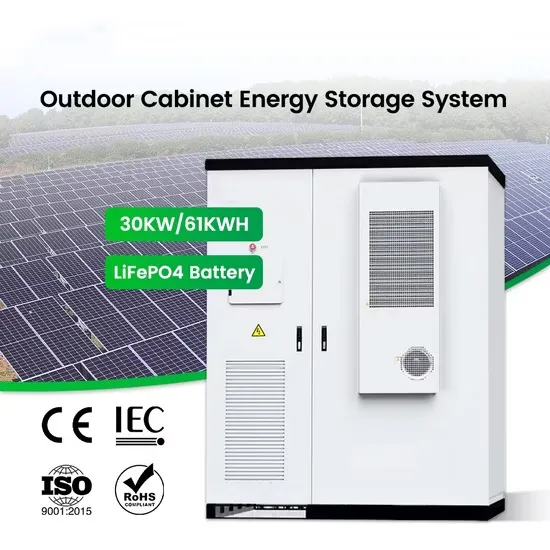

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.