Flywheel Energy Storage Systems and Their

Apr 1, 2024 · This study gives a critical review of flywheel energy storage systems and their feasibility in various applications. Flywheel energy storage systems

Nonlinear dynamic characteristics and stability analysis of energy

Jan 1, 2022 · In this paper, the nonlinear dynamic characteristics and stability of an energy storage flywheel rotor with shape memory alloys (SMA) damper are studi

Magnetic Levitation Flywheel Energy Storage System With Motor-Flywheel

Feb 13, 2025 · This article proposed a compact and highly efficient flywheel energy storage system. Single coreless stator and double rotor structures are used to eliminate the idling loss

The Status and Future of Flywheel Energy Storage

Jun 19, 2019 · The core element of a flywheel consists of a rotating mass, typically axisymmetric, which stores rotary kinetic energy E according to (Equation 1) E = 1 2 I ω 2 [J], where E is the

A Review of Flywheel Energy Storage System Technologies

Jul 6, 2024 · Using energy storage technology can improve the stability and quality of the power grid. One such technology is fly- wheel energy storage systems (FESSs). Compared with

Flywheel Energy Storage System

Flywheel Energy Storage Systems (FESS) are defined as systems that store energy by spinning a rotor at high speeds, converting the rotor''s rotational energy into electricity. They utilize a high

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extensively

A review of flywheel energy storage rotor materials and

Dec 25, 2023 · Therefore, the selection of appropriate rotor materials and the design of rotor structure are the key to reducing the cost of flywheel energy storage, which is crucial for the

Flywheel Energy Storage: Challenges in Microgrids

Feb 15, 2024 · While flywheel energy storage systems offer several advantages such as high-power density, fast response times, and a long lifespan, they also face challenges in microgrid

Design and Analysis of a Highly Reliable Permanent Magnet

Aug 13, 2024 · This article aims to propose a highly reliable permanent magnet synchronous machine (PMSM) for flywheel energy-storage systems. Flywheel energy-storage systems are

Applications of flywheel energy storage system on load

Mar 1, 2024 · Flywheel energy storage systems (FESS) are considered environmentally friendly short-term energy storage solutions due to their capacity for rapid and efficient energy storage

A Review of Flywheel Energy Storage System Technologies

Jul 6, 2024 · Keywords:flywheel energy storage systems (FESSs); flywheel rotors; flywheel motors; power electronic converters; machine learning 1. Introduction The demands for

A review of flywheel energy storage systems: state of the

Mar 15, 2021 · This paper gives a review of the recent Energy storage Flywheel Renewable energy Battery Magnetic bearing developments in FESS technologies. Due to the highly

Design of Flywheel Energy Storage System – A Review

Aug 24, 2024 · This paper extensively explores the crucial role of Flywheel Energy Storage System (FESS) technology, providing a thorough analysis of its components. It extens

Review of Flywheel Energy Storage Systems structures and applications

Mar 1, 2017 · Flywheel Energy Storage System (FESS) is an electromechanical energy storage system which can exchange electrical power with the electric network. It consists of an

High-Speed Kinetic Energy Storage System Development

Apr 8, 2025 · Flywheel energy storage systems (FESSs) can reach much higher speeds with the development of technology. This is possible with the development of composite materials. In

A review of flywheel energy storage systems: state of the art

Mar 16, 2024 · Thanks to the unique advantages such as long life cycles, high power density, minimal environmental impact, and high power quality such as fast response and voltage

Flywheel Energy Storage Systems and their Applications:

Oct 19, 2024 · Flywheel energy storage systems are suitable and economical when frequent charge and discharge cycles are required. Furthermore, flywheel batteries have high power

A Review of Flywheel Energy Storage System

May 7, 2017 · One energy storage technology now arousing great interest is the flywheel energy storage systems (FESS), since this technology can offer many advantages as an energy

A review of the structures and control strategies for flywheel

This paper investigates the mechanical structure of active magnetic, high-temperature superconducting magnetic, and hybrid bearings for a flywheel energy storage system. The

Structure and Optimization Design of Cup Winding

Feb 24, 2023 · A cup winding permanent magnet synchronous machine (PMSM) is proposed in the application of large-capacity flywheel energy storage system (FESS), which can effectively

Principles and application scenarios of flywheel

Aug 19, 2025 · Flywheel energy storage is an integrated technology, and its future development direction is high-speed, composite material rotor, and internal

Research on Taylor Vortex in the air-gap of flywheel energy storage

May 1, 2025 · Flywheel energy storage systems (FESSs) are high-speed rotating devices characterized by advanced technical requirements and a complex system structure. Current

A Review of Flywheel Energy Storage System Technologies

Flywheels have attributes of a high cycle life, long operational life, high round-trip efficiency, high power density, low environmental impact, and can store megajoule (MJ) levels of energy with

An Overview of the R&D of Flywheel Energy

Nov 5, 2024 · The literature written in Chinese mainly and in English with a small amount is reviewed to obtain the overall status of flywheel energy storage

6 FAQs about [Structure of flywheel energy storage]

What is a flywheel energy storage system?

As part of energy storage applications, flywheels perform storage applications both at the grid, as well as at the customer level. A brief description of some common applications associated with flywheel energy storage systems will now be given. 4.1.

What is a flywheel & how does it work?

Flywheels with the main attributes of high energy efficiency, and high power and energy density, compete with other storage technologies in electrical energy storage applications, as well as in transportation, military services, and space satellites .

How much energy can a flywheel store?

The small energy storage composite flywheel of American company Powerthu can operate at 53000 rpm and store 0.53 kWh of energy . The superconducting flywheel energy storage system developed by the Japan Railway Technology Research Institute has a rotational speed of 6000 rpm and a single unit energy storage capacity of 100 kW·h.

How to optimize the structure of composite flywheel energy storage system?

Arvin et al. used simulated annealing method to optimize the structure of composite flywheel and optimized the energy storage density of flywheel energy storage system by changing the number of flywheel layers.

What is a 7 ring flywheel energy storage system?

In 1999 , the University of Texas at Austin developed a 7-ring interference assembled composite material flywheel energy storage system and provided a stress distribution calculation method for the flywheel energy storage system.

What is flywheel/kinetic energy storage system (fess)?

and high power quality such as fast response and voltage stability, the flywheel/kinetic energy storage system (FESS) is gaining attention recently. There is noticeable progress in FESS, especially in utility, large-scale deployment for the electrical grid, and renewable energy applications. This paper gives a review of the recent

Update Information

- Flywheel energy storage motor structure

- Flywheel energy storage battery structure

- Windhoek 5G communication base station flywheel energy storage application

- Flywheel Energy Storage SOC

- How to develop flywheel energy storage for communication base stations

- Croatia has the most flywheel energy storage brands for communication base stations

- Flywheel Energy Storage Group Standard

- Key flywheel energy storage companies

- Flywheel hybrid energy storage

- Sales price of flywheel energy storage cabinet for communication base station

- Sana flywheel energy storage device

- 10kw flywheel energy storage price

- Construction of flywheel energy storage project for communication base station in Tajikistan

Solar Storage Container Market Growth

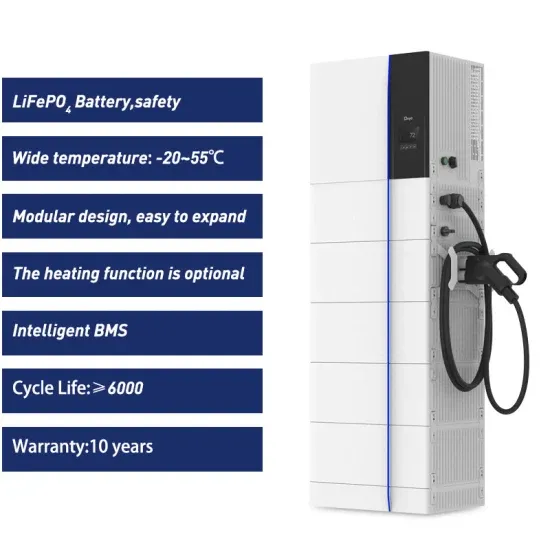

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

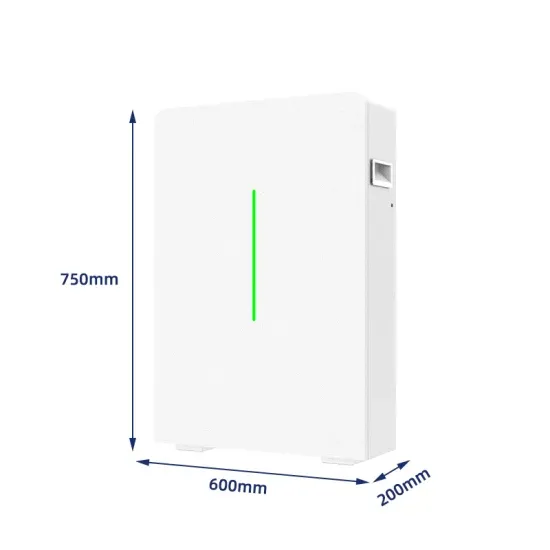

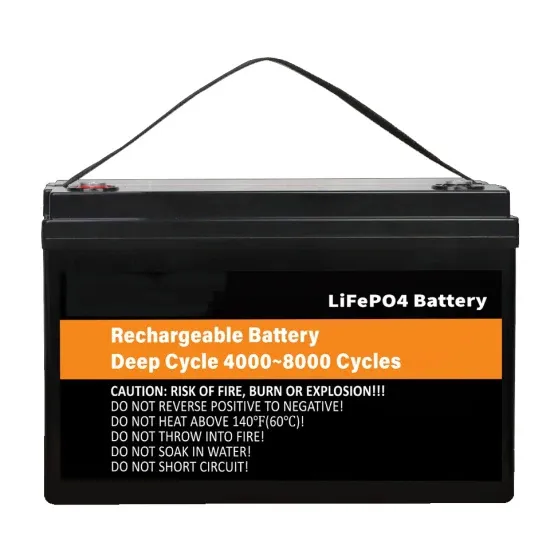

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.