aluminium expo |Aluminium for photovoltaics to show rapid

4 days ago · As a component that fixes and seals the battery cells, the frame needs to play a role in protecting the edge of the glass and strengthening the sealing of the component. At present,

INSTRUCTIONS FOR PREPARATION OF PAPERS

Jul 12, 2025 · The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum

What is the difference between a double-sided double-glass

May 22, 2025 · In terms of installation, double-sided double-glass modules usually need to be fixed with matching aluminum alloy frames or pressure blocks, and bottom ventilation space

Aluminium Solar Frame (Guide Rail)-Yonz Technology Co., Ltd.

Aluminium Solar Frame (Guide Rail) The design of an open cavity has stronger waterproofing, easier installation, lighter components, greatly increasing the service life of the components. At

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers.

What are the aluminum materials for solar energy? | NenPower

Oct 7, 2024 · Aluminum materials utilized in solar energy applications primarily encompass several types that play crucial roles in enhancing efficiency and durability. 1. Extruded

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · The connection between photovoltaic module and photovoltaic module bracket should be in the form of fixed aluminum alloy press block standard parts, rail groove insertion

Glass in the aluminum alloy of photovoltaic panels

Solar panel attachments are integral components in a solar system, including Glass, Encapsulation, Cell,Backsheet/Back glass, Junction Box(J-Box),Frame. This article will explain

Solar Panel Aluminum Frames: Aluminum Extrusions for

Jun 5, 2025 · Aluminum solar panel frames are essential solar panel components that provide structural support and protection for solar modules. Yes, this component can be created

4. SunRise Double Glass Topcon Solar Panel 580W Aluminum Alloy

Jun 23, 2025 · 4. SunRise Double Glass Topcon Solar Panel 580W Aluminum Alloy, Find Details and Price about bifacial panels glass topcon from 4. SunRise Double Glass Topcon Solar

Aluminium Alloys in Solar Power − Benefits and

Aug 16, 2013 · The superiority of aluminum alloys over steel is attributed to their lighter weight, higher strength, and more corrosion resistance using a thin

6 FAQs about [Solar double glass aluminum alloy components]

What is a double-glass solar module?

ABSTRACT: Double-glass modules provide a heavy-duty solution for harsh environments with high temperature, high humidity or high UV conditions that usually impact the reliability of traditional solar modules with backsheet material.

What is a double glass module?

The double glass module design offers not only much higher reliability and longer durability but also significant Balance of System cost savings by eliminating the aluminum frame of conventional modules and frame-grounding requirements. The application of double-glass modules covers multiple markets including utility, residential and commercial.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

Can a double-glass PV module withstand snow and ice?

frameless double-glass module and a traditional PV module with a 3.2mm glass with an aluminum frame were both qualified to withstand heavy accumulations of snow and ice under a high pressure of 5400Pa up to 6700Pa. modules are connected electrically in series until a maximum string voltage of 600 volt or 1,000 volt is achieved.

Are double glass modules better than traditional modules?

Compared to traditional modules with backsheet, modules with double glass are stronger and more durable, presenting less degradation due to thermal cycling stress. Results from the thermal cycling test up to 400 cycles show about 35% to 43% less degradation with double- glass modules than with traditional modules with backsheet (Fig. 3).

Update Information

- Glass material of double glass components

- Double glass 540 components

- Photovoltaic installation of double glass components

- 48 pieces of 182 double glass components

- Application scenarios of single and double glass components

- Installation of double glass light transmission components

- Light-transmitting components and double glass

- Use double glass components to make a sun room

- Romanian double glass module manufacturer

- What is a single crystal double glass module

- Battery cabinet aluminum alloy station cabinet

- What types of energy storage aluminum alloy products are there

- Huawei double glass floodlight module

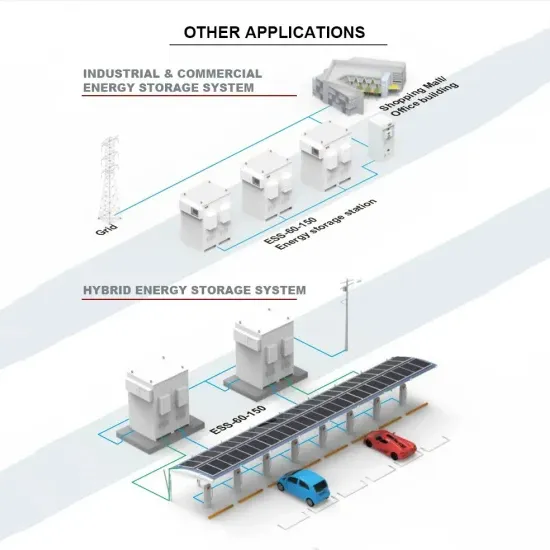

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.