Sun Wave's durable bifacial double glass modules

Our Double Glass Bifacial Modules: The Endurance and Power At Sun Wave, our commitment goes beyond delivering energy—we design solar technologies built to endure for decades.

Double-wave bifacial solar modules: Technological Evolution

Jul 25, 2025 · This article will conduct an in-depth analysis of the core characteristics, practical application value, as well as the opportunities and challenges it will face in the future of bifacial

The Glass-glass Module Using n-type Bifacial Solar Cell with

Aug 1, 2016 · In this work, the industrial glass-glass module was developed using bifacial n-type solar cell. The passivation emitter and rear total diffusion cells (PERT) structure solar cell

Towards 50 Year Lifetime PV Modules: Double Glass vs. Glass

Mar 29, 2024 · Bifacial modules with double glass architectures have been deployed to capture the rear-side irradiance thereby increasing the light captured. The choice of a double glass

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · The bifacial dual sided glass module (G2G) generates more electricity by converting direct, radiant and scattered solar energy on both the front and the back side of the module.

What are the differences between single-glass

Oct 22, 2020 · Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This

去护角 158.9 JAM72D09 370-390 BP

Oct 11, 2019 · Introduction JA bifacial modules are assembled by high-performance PERCIUM encapsulated by glass-glass panels, are capable of converting energy from lights on front and

Double-wave bifacial solar modules: Technological Evolution

Jul 25, 2025 · The photovoltaic industry is undergoing an efficiency and reliability revolution led by double-wave bifacial solar modules (commonly known as bifacial double-glass modules). This

Bi-facial Double Glass

Feb 22, 2023 · Our innovations are designed and engineered in Singapore. Among our product portfolio is the High-Power Density low-glare module (GMD series), 3-in-1 Building-Integrated

High performance double-glass bifacial PV modules

Oct 5, 2016 · Double-glass structure shows a loss of ~ 1.30% compare to the glass/backsheet structure under STC measurements. J. P. Singh, et al. "Comparison of Glass/glass and

Bi-facial Double Glass

Feb 22, 2023 · Among our product portfolio is the High-Power Density low-glare module (GMD series), 3-in-1 Building-Integrated solar roof materials (BiPV series), Bi-Facial double glass

What are bifacial solar modules and how do they

Apr 2, 2018 · There are frameless, dual-glass modules that expose the backside of cells but are not bifacial. True bifacial modules have contacts/busbars on

TRANSPARENT BACKSHEET VS. DUAL GLASS WHITE

Jul 30, 2023 · VS. DUAL GLASS WHITE PAPER but customers have a choice between transparent backsheet bifacial modules (TB) and dual glass bifacial modules (GG). This white

JinkoSolar: Transparent backsheet vs dual glass

Mar 10, 2020 · Bifacial with transparent backsheet and bifacial with dual glass have their own advantages and disadvantages. The radar chart can help customers evaluate the two products

Trina Solar launches N-type i-TOPCon double-glass bifacial modules

Jun 13, 2019 · The new i-TOPCon double glass PV modules integrate these N-type bifacial i-TOPCon cells with over 80% bifaciality, multi-busbar (MBB) design, full square

6 FAQs about [Double-glass modules and bifacial dual-wave modules]

What is a dual glass module?

Our dual glass modules use the same internal circuit connection as a traditional glass-backsheet module but feature heat-strengthened glass on both sides. We produce the back glass with a unique drilling technique that ensures the reliability of both the junction box installation and the module.

Why do bifacial modules need 2 mm glass?

As a result of the additional cost of very thin glass, most mass production bifacial modules being produced today are described as using 2 × 2.5 mm glass. More often, this means 3.2 mm on the front and 2 mm backsheet glass, states Weilharter – which brings down costs but in turn introduces its own issues.

What is double-glass bifacial module in 2019?

The double-glass bifacial module in 2019 is going to spread its wing starting from the domestic market. Under the pressure of subsidy-free plant development, such modules will be widely applied to utility-scale PV plants and then to distributed PV projects.

Can glass-glass modules catch the building bifacial wave?

Glass-glass modules are built to survive the toughest conditions and can deliver module lifetimes far exceeding the 20-30 years expected of glass-foil. The module concept is ideally positioned to catch the building bifacial wave, but only if quality concerns are addressed, warn some experts in the field.

What is bifacial glass technology?

Bifacial glass technology is the preferred material among manufacturers for the rear side cover of the modules. Some key advantages of the glass-glass structure are: Glass-glass modules can also be frameless, which helps eliminate the cost of an extruded aluminum frame. However, glass-glass models with frames have a lower risk of breakage.

Does Trina Solar have a dual glass bifacial module?

However, Trina Solar has made such a breakthrough by abandoning the backsheet and developing the brand-new dual glass module. Trina Solar Vertex TSM-DEG21C.20 (670 W) framed dual-glass bifacial module

Update Information

- Are double-glass bifacial modules polycrystalline

- Are bifacial modules double-glass modules

- Power generation of double-glass modules and single-glass modules

- Dual-wave or dual-glass modules

- Parameters of double-glass monocrystalline modules

- Double-glass photovoltaic modules in Rotterdam the Netherlands

- Which company is good at photovoltaic double-glass modules

- Applicable scenarios for double-glass photovoltaic modules

- High-efficiency double-glass solar photovoltaic modules

- Which companies have double-glass modules

- Photovoltaic modules double-glass double-sided

- Romanian double-glass photovoltaic modules

- Double-glass photovoltaic modules in Busan South Korea

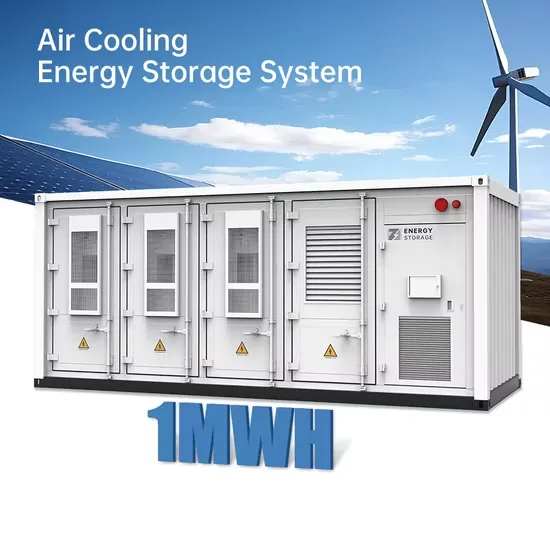

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.