Double Glass Technology: Harnessing Authentic Advantages

Nov 29, 2023 · Double glass photovoltaic modules stand out with remarkable advantages in power generation, embodying authenticity in their performance. The transparency and robust

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · Functional level: longer life cycle PERC double-glass double-sided modules integrate the anti-PID characteristics of double-glass modules, and have the advantages of high

Study on the comprehensive ratio of power generation

This paper conducted a comparative power generation capability test of N-type bifacial double-glass photovoltaic modules under multiple scenarios in Yinchuan, Ningxia (north

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · The structure of double-sided double-glass modules includes: double-layer glass + frameless structure; double-sided (with frame) modules adopt Transparent backplane + border

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

JA SOLAR JAM54D41-450/LB Module – Full black – Bifacial

JA Solar DEEP BLUE 4.0 Pro JAM54D41 LB Photovoltaic Modules The JA Solar DEEP BLUE 4.0 Pro series JAM54D41 LB photovoltaic modules are high-performance, bifacial (double-sided) n

How durable is the double-sided double-glass n-type

In ground photovoltaic power stations, double-sided modules can reduce land occupation and increase power generation per unit area summary, double-sided double-glass n-type

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · The thickness of the front glass generally used for this type of structure is 3.2 mm. Dual-glass type modules (also called double glass or glass-glass) are made up of two glass

Customize for Middle Asia Europe South America Markets

Jul 21, 2025 · Customize for Middle Asia Europe South America Markets 420W to 440W Double Sided Glass Solar Photovoltaic Modules, Find Details and Price about Photovoltaic Modules

What are Double Glass Solar Panels?

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

6 FAQs about [Photovoltaic modules double-glass double-sided]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What is the electrical performance of BYD double-glass modules?

The electrical performance of the BYD double-glass modules was as expected for multicrystalline cells, with power bins ranging from 245W to 265W for 60-cell modules, and from 295W to 315W for 72-cell modules. The modules were subjected to numerous accelerated ageing tests.

Are early PV modules encapsulated with silicone?

Photovoltaics International Early PV modules were often encapsulated with silicone, and have demonstrated outstanding stability in the field, with degradation rates over 20 to 30 years that are much lower than the typical degradation rates for EVA-encapsulated modules [3–5].

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

What encapsulant materials can be used for PV modules?

Various encapsulant materials can be considered. Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules.

Update Information

- Latvian double-glass photovoltaic modules

- Which company is good at photovoltaic double-glass modules

- Double-glass photovoltaic modules in Toronto Canada

- Lifespan of double-sided double-glass modules

- Single-sided and double-sided photovoltaic modules

- Can double-glass photovoltaic panels be made into single crystal

- Russia St Petersburg double glass photovoltaic modules

- How much is the price of double-glass photovoltaic curtain wall in Brussels

- How much is the price of photovoltaic modules in Kigali

- What is double-glass photovoltaic glass

- Inverter ratio of photovoltaic modules

- Double-sided glass photovoltaic sun room

- Photovoltaic modules on communication base station inverter

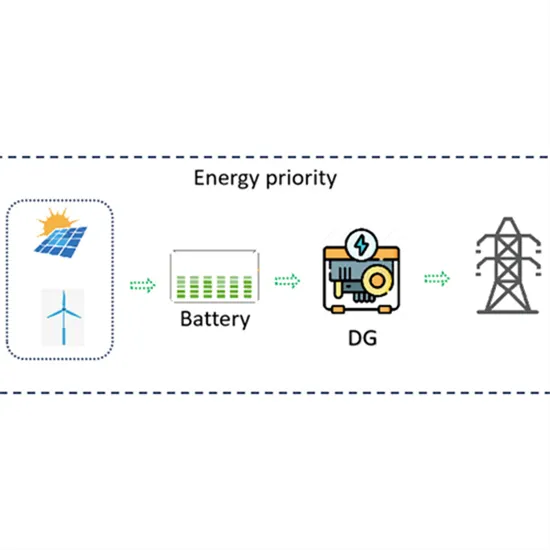

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

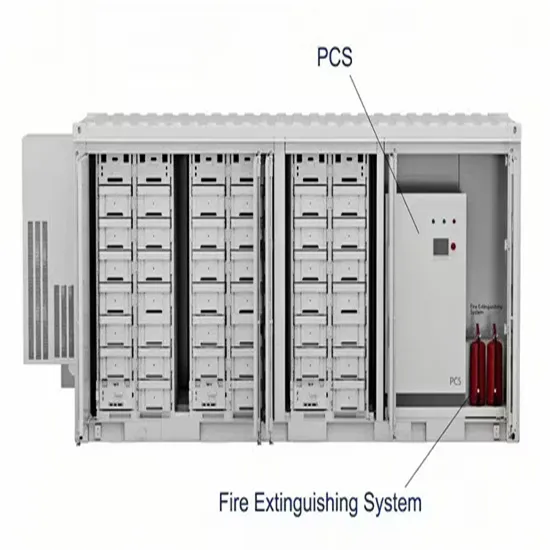

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.