Design of Solar Modules for Building Façades at

Apr 25, 2021 · Photovoltaic (PV) panels are the most widely used technology for renewable energy production; however, in urban areas, their installation

SOUTH KOREA''S SOLAR POWER INDUSTRY: STATUS

Jan 2, 2024 · Introduction China''s growing global market dominance in solar photovoltaic (PV) supply chains has created considerable challenges for South Korea''s PV industry in various

JA Solar Supplies Modules For The Largest PERC Bifacial Double-Glass

In December 2018, JA Solar became one of the first PV companies to obtain product certification from Korea Standards Association (KS) for its PERC bifacial double-glass module. The

Single Glass Photovoltaic Curtain Wall Manufacturer in

As a single glass photovoltaic curtain wall manufacturer in Busan, South Korea, our focus is merging cutting-edge solar technology with modern architectural design. Busan''s strategic

Final Price Reduced to $0.118/kWh for South Korea 2GW Solar Projects

Mar 12, 2024 · It is planned to allocate 2050MW of renewable energy, and the final average price is 136.128 won per kWh, 7.5 won lower than previous bidding. Ningbo Raytech New Energy

South Korea PVB Double Glass Photovoltaic Module Market

Aug 11, 2024 · The South Korea PVB double glass photovoltaic module market is segmented based on diverse applications, each catering to specific energy needs and deployment scales.

Agenda 55th PVPS ExCo Mtg

Apr 27, 2021 · Use of polyolefin encapsulants largely prevents PID. Double-glass bifacial modules using EVA encapsulant can be more susceptible to PID due to the increased availability of

Double Glass Module Photovoltaic Glass Market

Key Drivers Accelerating Double Glass Module Adoption in the Global Photovoltaic Market The shift toward double glass modules in the photovoltaic industry is driven by their **superior

Double-glass PV modules with silicone encapsulation

May 21, 2024 · Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

JA Solar Supplies Modules for the Largest PERC Bifacial Double-glass

Sep 22, 2023 · BEIJING, July 11, 2019 /PRNewswire/ -- JA Solar Co., Ltd, a world-leading manufacturer of high-performance photovoltaic products, announced that it supplied all

Growth Strategies in Double Glass Module Photovoltaic Glass

Jan 17, 2025 · The global double glass module photovoltaic glass market is projected to reach a value of USD 29.5 billion by 2033, exhibiting a CAGR of 11.5% during the forecast period from

JA Solar Supplies Modules for the Largest PERC Bifacial Double-glass

Jul 12, 2019 · JA Solar Co., Ltd, a world-leading manufacturer of high-performance photovoltaic products, announced that it supplied all modules for the largest PERC bifacial double-glass

JA Solar Supplies Modules For The Largest PERC Bifacial Double-Glass

JA Solar''s PERC bifacial double-glass modules can further increase energy yield for the PV system and effectively drive down LCOE, providing customers in South Korea who focus on

JA Solar supplies modules for the largest PERC

Jul 12, 2019 · JA Solar''s PERC bifacial double-glass modules can further increase energy yield for the PV system and effectively drive down LCOE, providing

JA Solar DeepBlue 3.0 Series Successfully Obtains the 182 Module

Jan 25, 2021 · It has supplied modules for large-scale PV plants in South Korea, including the largest wind-solar hybrid project, the largest PERC bifacial double-glass project in the local

Ja for South Korea''s biggest PERC double double glass plant

Solar photovoltaic (pv) net news: recently, ja solar announced that for South Korea''s biggest PERC double double glass photovoltaic projects supply all effective component, the

Double Glass Module Photovoltaic Glass Unlocking Growth

Mar 29, 2025 · The double-glass module photovoltaic (PV) glass market is experiencing robust growth, driven by increasing demand for higher efficiency and durability in solar energy

Trina Solar''s First Photovoltaic Power Station in

Dec 28, 2020 · The Jincheon photovoltaic power station has an installed capacity of 500kW, adopts Trina Solar''s high-efficiency bifacial double-glass modules,

JA Solar Supplies Modules for the Largest PERC Bifacial Double-glass

Jul 12, 2019 · JA Solar''s PERC bifacial double-glass modules can further increase energy yield for the PV system and effectively drive down LCOE, providing customers in South Korea who

Field degradation prediction of potential induced

Sep 1, 2017 · Potential-induced degradation (PID) was first introduced in 2010 as a degradation mode of crystalline silicon photovoltaic (PV) modules in field [1], [2]. Due to the voltage

JA Solar supplies modules for double-glass solar project in South Korea

Jul 17, 2019 · JA Solar''s PERC bifacial double-glass modules can further increase energy yield for the PV system and effectively drive down LCOE, providing customers in South Korea who

Busan plant becomes Höganäs'' first 100% solar-powered

Jan 29, 2025 · With its new solar panels, Höganäs'' plant in Busan, Korea is the first within the company to run 100 per cent on renewable energy from solar panels. At the beginning of

6 FAQs about [Double-glass photovoltaic modules in Busan South Korea]

Are double-glass PV modules durable?

Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability.

What is a double glass c-Si PV module?

Recently several double-glass (also called glass–glass or dual-glass modules) c-Si PV modules have been launched on the market, many of them by major PV manufacturers. These modules use a sheet of tempered glass at the rear of the module instead of the conventional polymer-based backsheet. There are several reasons why this structure is appealing.

What encapsulant materials can be used for PV modules?

Various encapsulant materials can be considered. Polyvinyl butyral (PVB) has been used for a long time for glass–glass PV modules, particularly for thin-film modules.

What is the electrical performance of BYD double-glass modules?

The electrical performance of the BYD double-glass modules was as expected for multicrystalline cells, with power bins ranging from 245W to 265W for 60-cell modules, and from 295W to 315W for 72-cell modules. The modules were subjected to numerous accelerated ageing tests.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

Are early PV modules encapsulated with silicone?

Photovoltaics International Early PV modules were often encapsulated with silicone, and have demonstrated outstanding stability in the field, with degradation rates over 20 to 30 years that are much lower than the typical degradation rates for EVA-encapsulated modules [3–5].

Update Information

- Photovoltaic solar panel brand in Busan South Korea

- Efficiency comparison between double-glass and single-glass photovoltaic modules

- Ranking of Super Capacitor Manufacturers in Busan South Korea

- Applicable scenarios for double-glass photovoltaic modules

- Which company is good at photovoltaic double-glass modules

- Busan South Korea energy storage equipment new energy enterprise

- Double-glass photovoltaic modules in Toronto Canada

- Naypyidaw double-glass photovoltaic modules

- High-efficiency double-glass solar photovoltaic modules

- South Korea Busan MW energy storage container

- Busan Air Energy Storage Project in South Korea

- Energy storage power supply companies in Busan South Korea

- The largest photovoltaic energy storage company in South America

Solar Storage Container Market Growth

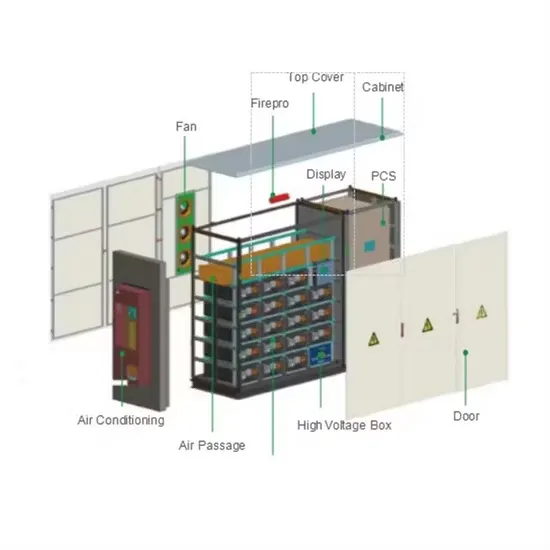

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.