Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · To bifacial PV module, the backsheet is either glass or transparent polymeric materials. Many studies have shown that compared with double-glass solar modules, the

What are the differences between single-glass

Oct 22, 2020 · Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This

JA SOLAR PV BIFACIAL DOUBLE-GLASS MODULES

Mar 31, 2025 · For the bifacial modules, in order to maintain the energy yield of module rear side, the distance between the bottom of modules and the roof or ground surface is recommended

JA Solar PV Bifacial Double-glass Modules Installation

Jan 21, 2025 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

Towards 50 Year Lifetime PV Modules: Double Glass vs. Glass

Mar 29, 2024 · Bifacial modules with double glass architectures have been deployed to capture the rear-side irradiance thereby increasing the light captured.

For N-type Bifacial Technology, Dual Glass Structure is

Feb 28, 2023 · The reflectance and transmittance of n-type modules with glass/glass structures can maximize the higher bifacial Factor advantage of n-type TOPCon cell, providing

BIFACIAL SERIES – GLASS-TO-GLASS PHOTOVOLTAIC

Dec 4, 2012 · The bifacial dual sided glass module (G2G) generates more electricity by converting direct, radiant and scattered solar energy on both the front and the back side of the module.

Bi-facial Double Glass

Feb 22, 2023 · Our innovations are designed and engineered in Singapore. Among our product portfolio is the High-Power Density low-glare module (GMD series), 3-in-1 Building-Integrated

Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · Many studies have shown that compared with double-glass solar modules, the combination of glass front sheet and transparent backsheets has the following advantages:

The Glass-glass Module Using n-type Bifacial Solar Cell with

Aug 1, 2016 · In this work, the industrial glass-glass module was developed using bifacial n-type solar cell. The passivation emitter and rear total diffusion cells (PERT) structure solar cell

JA Solar PV Bifacial Double-glass Modules Installation

Nov 20, 2024 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules.

JA Solar PV Bifacial Double-glass Modules

Feb 1, 2021 · JA Solar modules can be mounted in landscape or portrait orientation. For the bifacial modules, in order to maintain the energy yield of module rear side, the distance

JA Solar PV Bifacial Double-glass Modules Installation

Jul 18, 2025 · This Installation Manual contains essential information for electrical and mechanical installation that you must know before handling and installing JA Solar modules. This Manual

Bifacial photovoltaic panels: the new

Jan 22, 2020 · Finally, most bifacial PV modules are made with a rear-glass backsheet ("glass-glass" or double glass" modules), which improves module

What are the advantages of dual-glass Dualsun modules?

Aug 18, 2025 · Bifaciality: The bifaciality of double glass modules produces a gain of around 10-11% compared to the power measured on the front panel alone, for TOPCon type modules

6 FAQs about [Are bifacial modules double-glass modules ]

What is a bifacial G-B module?

Bifacial G-B modules use a 3.2 mm-thick tempered glass on the front, delivering superior impact strength and durability in comparison to the 2 mm–2.1 mm thick heat-treated glass typically used in G-G modules. The glass used in PV modules generally has a UV transmittance of 40%-50%.

Why are bifacial glass-backsheet modules becoming more popular?

In recent years, an increasing number of module manufacturers have shifted towards transparent backsheets due to their numerous advantages over traditional glass modules. Bifacial Glass-Backsheet (G-B) modules are 17% lighter than Glass-Glass (G-G) modules.

How are bifacial solar panels made?

There are two common methods for making bifacial solar PV modules: The first involves using glass layers on both the front and rear sides of the panel, referred to as “Glass-Glass PV Modules," "Double Glass PV Modules," or "Dual-Glass PV Modules."

What is a bifacial PV module?

Unlike traditional PV modules, bifacial modules can generate power from both the front and the back, resulting in higher power output within the same space. This has made them a popular choice for many types of installations.

Why are double glass modules symmetrical?

Mechanical constraints on cells: the fact that the structure of the double glass modules is symmetrical implies that the cells are located on a so-called neutral line, the upper part of the module being in compression during a downward mechanical load and the lower glass surface being in tension.

What is a dual-glass module?

Dual-glass type modules (also called double glass or glass-glass) are made up of two glass surfaces, on the front and on the rear with a thickness of 2.0 mm each. Some manufacturers, in order to reduce the weight of the modules, have opted for a thickness of 1.6 mm. DualSun has chosen to stay with a thickness of 2.0 mm for reasons explained below.

Update Information

- Are double-glass bifacial modules polycrystalline

- Double-glass modules and bifacial dual-wave modules

- Power generation of double-glass modules and single-glass modules

- Parameters of double-glass monocrystalline modules

- Double-glass photovoltaic modules in Rotterdam the Netherlands

- Latvian double-glass photovoltaic modules

- Naypyidaw double-glass photovoltaic modules

- Romanian double-glass photovoltaic modules

- Applicable scenarios for double-glass photovoltaic modules

- Photovoltaic modules double-glass double-sided

- Guinea-Bissau double-glass photovoltaic curtain wall design

- Prices of three major types of photovoltaic modules

- How many watts of solar power modules should I buy

Solar Storage Container Market Growth

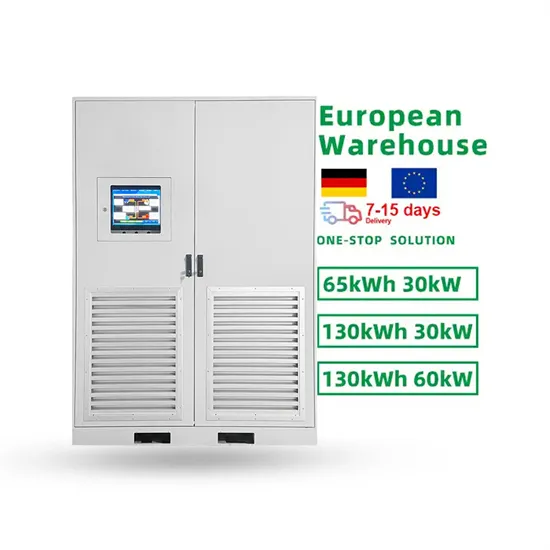

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.