Solar power generation panel double glass

Glass-glass module structures (Dual Glass or Double Glass) is a technology that uses a glass layer on the back of the modules instead of the traditional polymer backsheet. Originally

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Double Glass Technology: Harnessing Authentic Advantages

Nov 29, 2023 · Double glass photovoltaic modules stand out with remarkable advantages in power generation, embodying authenticity in their performance. The transparency and robust

Current Status And Future Development Trends of Single And Double Glass

Jun 17, 2024 · Since single-glass modules are lighter in weight, single-glass modules can save manpower, transportation and other systemic costs., especially suitable for installation in sites

Experimental investigation on the combustion performance of single

Jun 15, 2025 · In pursuit of ''carbon peaking and carbon neutrality'' objectives, fire incidents have become increasingly common in photovoltaic power generation systems. The combustion

The Performance of Double Glass Photovoltaic Modules

Sep 17, 2023 · The 15th International Double Glass Composite Glass Photovoltaic Photovoltaic Modules Symposium on Test Conditions District Heating and Cooling under Composite

Bifacial single glass encapsulation of solar module – An

Outdoor performance of PV modules encapsulated with two different approaches showed that annual power generation of single glass solar modules was higher than that of double glass

The Advantages of Double-glass Modules

Mar 11, 2022 · High temperature will reduce the power generation of the module, and the double-glass module has better heat dissipation than the single-glass module in this regard, thus

Single-glass versus double-glass: a deep dive into module

Oct 2, 2024 · There has been a noteable shift from the initial single-facial single-glass modules to bifacial double-glass modules. Double-glass modules, with their performance in the face of salt

Study on the comprehensive ratio of power generation

By evaluating the power generation capabilities of bifacial double-glass modules and single-sided N-type modules on different ground types (artificial grass, concrete, sandy soil, white paint,

Power generation ratio of double-glass photovoltaic

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which can impact their durability,

The comparison of Trombe wall systems with single glass, double glass

Sep 1, 2012 · In this paper, the energy performance comparison of single glass, double glass and a-Si semi-transparent PV module integrated on the Trombe wall façade of a model test room

Double-glass solar panel power generation efficiency

Preface To further extend the s rvice life of photovoltaic modules,double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module

TOPCon Bifacial Single Glass Encapsulation Solution

Sep 6, 2024 · single glass module can release acetic acid produced by the encapsulation film inside the module because of its breathing function, and the outdoors use reliability is better;

What are the differences between single-glass

Oct 22, 2020 · Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and

Bifacial single glass encapsulation of solar module – An

Jul 1, 2025 · Outdoor performance of PV modules encapsulated with two different approaches showed that annual power generation of single glass solar modules was higher than that of

Double-glass solar power generation installation

Flexible vs. Rigid Double-Glass Solar Panels: Which One is Your Which is better, single-glass or double-glass solar panels? Overall, double-glass solar panels outperform single-glass

Solar power generation panel double glass

Longi double-glass modules have better performance than other types of double-glass modules, and the power generation of conventional single crystal on flat single-axis supports has

Double Glass Module Photovoltaic Glass Market

The shift toward double glass modules in the photovoltaic industry is driven by their **superior durability, higher energy yield, and alignment with sustainability goals**. Unlike traditional

A systematic literature review of the bifacial photovoltaic module

Aug 12, 2024 · However, glass/glass PV modules with bifacial solar cells deliver extra power in outdoor settings due to absorption from the module''s rear side. As a result, a glass/glass

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · Functional level: longer life cycle PERC double-glass double-sided modules integrate the anti-PID characteristics of double-glass modules, and have the advantages of high

6 FAQs about [Power generation of double-glass modules and single-glass modules]

What is a double glass module?

Double glass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet. With * Corresponding author. Tel.: +86 13776101913; fax: +86 51268961413.

What is double glass photovoltaic module?

Preface To further extend the s rvice life of photovoltaic modules, double glass photovoltaic module has cently been develop d and st died in the PV community. Double lass module contains two sheets of glass, whereby the back sheet is made of heat strengthened (semi-tempered) glass to substitute the traditional polymer backsheet.

How reliable is Canadian Solar's Dymond double glass module?

Canadian Solar’s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully indicate high lifetime and high reliability of this double glass module. This paper presents a detailed reliability study of Canadian Solar’s Dymond double glass module.

Are double-glass solar modules reactive or non-reactive?

Furthermore, comparing to plastic backsheets (the back material of single-glass solar module) which are reactive, glass is non-reactive. This means that the whole structure of Raytech double-glass solar modules (two layers of glass and one layer of solar cells in the middle) are highly resistant to chemical reactions such as corrosion as a whole.

What is tempered glass solar module?

Single-glass Solar Module: As the first layer of materials in the solar module structure, tempered glass can effectively protect the panel and solar cells against physical stress, snow, wind, dust and moisture etc, at the same time guaranteeing that the sunlight can go in. The backside is generally protected by an opaque sheet called the backsheet.

Why is white double glass PV module more powerful than transparent?

Due to the high reflectance of white EVA, the power of white double glass module is higher than that of transparent double glass module by 2-4%. Double glass PV modules is an area of significant investigation by many companies and institutes in recent years, for example Dupont, Trina, Apollon, SERIS, MIT, Meyer Burger and Talesun.

Update Information

- Double-glass module power generation efficiency

- Efficiency comparison between double-glass and single-glass photovoltaic modules

- Belarusian glass photovoltaic power generation

- Canada Photovoltaic Panel Grid-connected Power Generation Project

- 60kw solar power generation system

- Oslo large-scale energy storage power generation project

- Sucre solar power generation and energy storage costs

- Self-use wind and solar hybrid power generation system

- Paraguay power generation panels photovoltaic panels

- Solar 30 watt power generation panel

- Solar panels photovoltaic power generation in Pakistan

- Somaliland bifacial solar panels power generation

- North American communication base station photovoltaic power generation system bidding

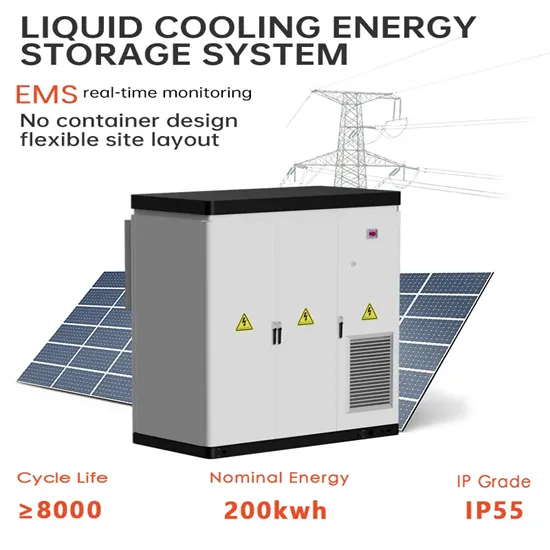

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.