Castrie Advantage Lithium Battery

Why is lithium ion battery better than other rechargeable batteries? Better Energy EfficiencyThe main advantage of lithium-ion battery over other rechargeable batteries is energy efficiency.

Lithium-Ion Battery Manufacturing: Industrial

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting

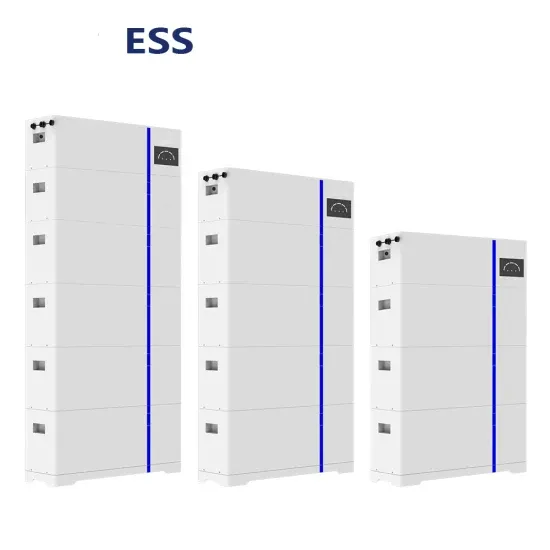

Castrie Battery Energy Storage Battery

Castrie Battery Energy Storage Battery Residential solar energy systems paired with battery storage--generally called solar-plus-storage systems--provide power regardless of the weather

PRODUCTION PROCESS OF A LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Battery Pack Assembly Line Digital Process Documentation

Jul 15, 2025 · Digital process documentation transforms battery pack assembly lines by replacing static manuals with interactive, real-time guides. Imagine technicians accessing step-by-step

Castrie Cryogenic Lithium Battery Company

Journal Article: Effects of Cryogenic Freezing Upon Lithium-Ion Battery Safety and Component Integrity Recycling capacity for lithium-ion batteries (LIBs) has not kept pace with the

Understanding the Lithium-Ion Battery Manufacturing Process

Aug 5, 2025 · This means that during the battery''s operation, lithium ions move from the anode to the cathode through an electrolyte, and then back again when charging. The efficiency of this

Designing a Lithium-Ion Battery Pack: A Comprehensive Guide

Feb 15, 2025 · Designing a lithium-ion battery pack is a complex and multifaceted process that requires a deep understanding of the components, configurations, and safety considerations

Castrie lithium battery packaging equipment company

What Li-ion battery packaging materials does Targray offer? Targray supplies customizable Lithium-ion Battery packaging materials for the 3 primary geometric battery configurations -

Castrie lithium battery sales manufacturers ranking

What are the top 10 power lithium battery manufacturers in the world? The world''s top 10 Power Lithium battery manufacturing companies include China''s CATL, BYD Company, Panasonic,

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Festo offers high-precision automation components for battery manufacturing with pneumatic and electric actuators, valves, and handling systems to improve electrode coating,

Castrie battery drying room manufacturer

The Dry-room is mainly used in the manufacturing process of lithium ion batteries, lithium ion polymer batteries, lithium solid-state batteries, electrolytes, and secondary battery materials.

Lithium Battery Pack Process: Assembly, Management and

The pack process of lithium battery involves many links such as the assembly, management and protection of battery cells, which has an important impact on the performance and safety of

Lithium-Ion Battery Manufacturing: Industrial View on

Nov 15, 2023 · In this review paper, we have provided an in-depth understanding of lithium-ion battery manufacturing in a chemistry-neutral approach starting with a brief overview of existing

Castrie low temperature lithium battery batch customization

How to overcome Lt limitations of lithium ion batteries? Two main approaches have been proposed to overcome the LT limitations of LIBs: coupling the battery with a heating element to

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · EQUIPMENT FOR LIB MANUFACTURING Manufacturing process The rapidly energy as global part because storage. of demand global of The efforts for the transition Li-ion

Castrie Lithium Battery Pack Processing Innovations in

Summary: Explore how Castrie lithium battery pack processing technology revolutionizes energy storage across industries. Discover key applications, market trends, and technical

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Conclusion The process of lithium-ion battery pack manufacturing involves meticulous steps from cell sorting to final testing and assembly. Each

6 FAQs about [Castrie lithium battery pack processing]

What are the production steps in lithium-ion battery cell manufacturing?

Production steps in lithium-ion battery cell manufacturing summarizing electrode manufacturing, cell assembly and cell finishing (formation) based on prismatic cell format. Electrode manufacturing starts with the reception of the materials in a dry room (environment with controlled humidity, temperature, and pressure).

How are lithium ion batteries made?

State-of-the-Art Manufacturing Conventional processing of a lithium-ion battery cell consists of three steps: (1) electrode manufacturing, (2) cell assembly, and (3) cell finishing (formation) [8, 10].

Is vacuum deposition a safe method for lithium ion battery manufacturing?

The vacuum deposition technique is generally a slow and expensive method, making it incompatible with the current industrialization speed of lithium-ion battery manufacturing. Moreover, there are safety concerns due to the lithium metal used.

How can localization improve battery manufacturing?

Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system. With strategic planning and proper investment in partnerships, regions will reduce their reliance on specific manufacturers and turn to key players in the global battery market for the widespread adoption of electrification.

How can a local battery manufacturing system help a battery plant?

Local manufacturers will scale up and cover the entire machinery for a battery plant through collaborations, from producing electrodes to the final cell formation. Localizing innovation and equipment manufacturing will build a sustainable and competitive battery manufacturing system.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the transferability of competencies from the production of lithium-ion battery cells is discussed. The publication “Battery Module and Pack Assembly Process” provides a comprehensive process overview for the production of battery modules and packs.

Update Information

- Lima Power Lithium Battery Pack Processing

- Berlin lithium battery pack processing

- Indian lithium battery pack processing

- Lithium battery pack processing in Southern Europe

- Dominic lithium battery pack processing

- Dakar lithium battery pack processing

- Tirana 21700 lithium battery pack manufacturer

- Foldable lithium battery pack

- 12V 3-channel 4-channel lithium iron phosphate battery pack

- Electric measurement of peak discharge of lithium battery pack

- Lithium battery pack consists of several cells

- Allowable range of capacity difference of Honiara lithium battery pack

- Argentina electric stacker lithium battery pack

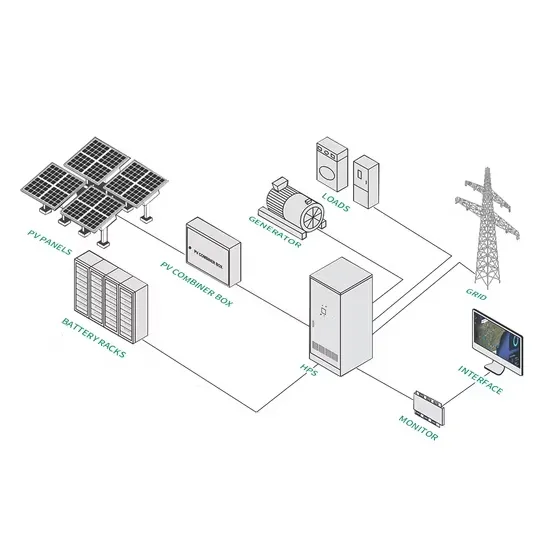

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.