Lithium Battery Pack Specifications, Size Standards and

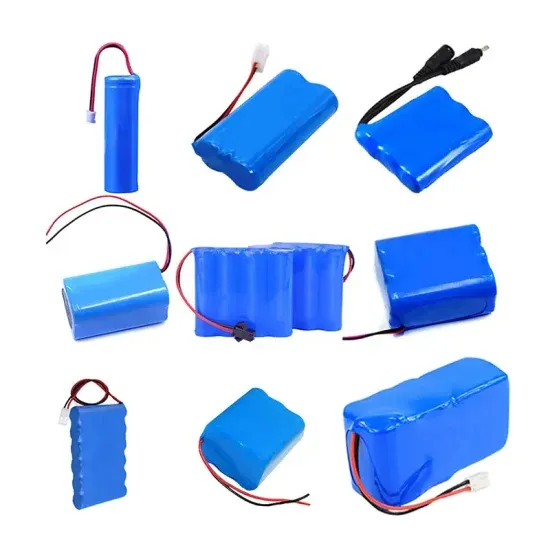

Apr 23, 2024 · the voltage capacity of lithium battery pack refers to the amount of electrical energy that the battery pack can store, usually expressed as voltage (V) and capacity (Ah). Lithium

Consistency evaluation of Lithium-ion battery packs in

Dec 20, 2024 · The battery pack inconsistency is affected by factors such as battery capacity, internal resistance, and self-discharge rate during use, resulting in differences in aging and

Determination of the battery pack capacity considering the estimation

Sep 1, 2016 · Lithium-ion batteries have been widely used as the power source of electric vehicles (EVs) in recent years [1], [2]. Generally, the battery system for EVs is composed of numerous

Cell-to-Cell Variation and Deterministic Pack

Apr 30, 2024 · 2. Pack Capacity is Determined by Random Cell-to-Cell Variations and Deterministic Thermal Offsets One explanation for the larger cell-to-cell

Lipo Battery Guide: Key Specs & Performance

Mar 26, 2025 · Learn everything about Lipo batteries—capacity, energy density, cycle life, and more. Optimize performance and avoid common pitfalls with this

Honiara lithium battery pack voltage is unbalanced

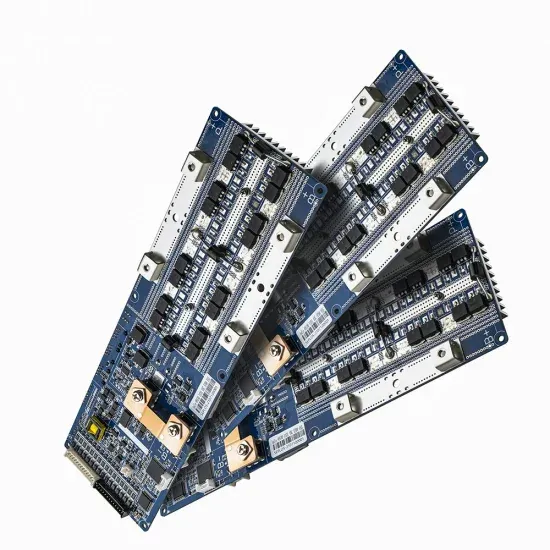

Active battery balancing is a method of maintaining the state of charge of individual cells in a battery pack. In a multi-cell battery system, for example in electric cars or energy storage

Capacity evaluation and degradation analysis of lithium-ion battery

Aug 15, 2023 · In this paper, a capacity calculating method specialized for EVs is proposed. This method uses an open circuit voltage (OCV) correction strategy to guarantee the credibility of

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Cell Form Factors & Lithium Battery Sizes in Pack

Apr 9, 2024 · Each packaging type has a variety of sizes, the cell size refers to its physical dimensions and capacity, often measured in ampere-hours (Ah) or

220v battery pack voltage allowable range

How to size your storage battery pack : calculation of Capacity, C-rating (or C-rate), ampere, and runtime for battery bank or storage system (lithium, Alkaline, LiPo, Li-ION, Nimh or Lead batteries

Which lithium battery pack is better in Honiara

Calculation of battery pack capacity, c-rate, run-time, charge and discharge current Battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION, Nimh or Lead batteries .

Allowable voltage difference of single cells in lithium battery pack

Here''''s a useful battery pack calculator for calculating the parameters of battery packs, including lithium-ion batteries. Use it to know the voltage, capacity, energy, and maximum discharge

Liquid-cooled energy storage battery pack allowable voltage difference

What is a direct liquid cooling strategy for EV batteries? One of these has been developed by M. Larrañaga et al. who proposed a novel direct liquid cooling strategy for the EVs battery pack. It

Capacity estimation for series-connected battery pack based

Aug 1, 2024 · Subsequently, by optimizing the transformation coefficients, we achieve capacity estimation for each cell within the battery pack utilizing only a partial charging voltage profile at

An online SOC and capacity estimation method for aged lithium

Jun 1, 2020 · For lithium-ion battery packs, especially aged lithium-ion batteries, the inconsistencies in State-of-Charge (SOC), model parameter and capacity between cells

State-of-charge inconsistency estimation of lithium-ion battery pack

Apr 15, 2018 · State-of-charge (SOC) inconsistency impacts the power, durability and safety of the battery pack. Therefore, it is necessary to measure the SOC inconsistency of the battery pack

The Handbook of Lithium-Ion

Aug 16, 2025 · The Handbook of Lithium-Ion Battery Pack Design This page intentionally left blank The Handbook of Lithium-Ion Battery Pack Design Chemistry, Components, Types and

Allowable voltage difference of lithium battery pack

A lithium battery voltage chart is an essential tool for understanding the relationship between a battery''s charge level and its voltage. The chart displays the potential difference between the

Battery Pack Cell Voltage Difference and Solution Part 1

Aug 5, 2024 · Achieving good capacity, state of charge, internal resistance, and self-discharge consistency is essential for maximizing and utilizing the battery

A Guide to Understanding Battery Specifications

Dec 18, 2008 · For a battery with a capacity of 100 Amp-hrs, this equates to a discharge current of 100 Amps. A 5C rate for this battery would be 500 Amps, and a C/2 rate would be 50 Amps.

Analysis of the standard for lithium battery capacity

Requirements for lithium battery assembly: Capacity difference ≤ 30mAh, voltage difference ≤ 3mV, internal resistance difference ≤ 3m Ω. Of course, the battery cell model must be the

6 FAQs about [Allowable range of capacity difference of Honiara lithium battery pack]

Is there a standard size lithium-ion battery pack?

Perhaps the first and most important statement we can make about battery packaging is this: there is no standard size lithium-ion battery pack and there is not likely to be one in the near future.

How many cells does a NiMH battery pack need?

For instance, a NiMh battery pack with 350V may require 292 cells to achieve that voltage (350V/1.2V = 292 cells). Whereas a lithium-ion-based battery pack would only require about 98 cells to achieve the same system voltage (350V/3.6V = 98 cells).

How EV battery pack capacity is determined?

Pack Capacity is Determined by Random Cell-to-Cell Variations and Deterministic Thermal Offsets One explanation for the larger cell-to-cell variation in used EV battery packs is the non-homogeneous load that each cell receives in real-life batteries. For instance, imperfect cooling systems result in a thermal gradient along the battery pack.

Are all lithium-ion batteries compatible?

While this may seem like a “no brainer,” the lithium-ion battery industry is only just beginning to get to some level of standardization so there are still many solutions available and each has different costs/benefits—and they are not all compatible with each other!

What are the requirements to ship lithium ion cells?

• Section 38.3 of the United Nations Handbook on the Transportation of Dangerous Goods regulates the testing that must be done in order to ship lithium-ion cells, modules, and packs. • Marine applications require type approval and certification by agencies such as DNV-GL, Lloyd’s, and ABS. This page intentionally left blank 153

What are the characterization and testing requirements for lithium-ion batteries?

The rest of the characterization and testing requirements are very similar to all other lithium-ion batteries and will include electrical performance and characterization testing, abuse testing, and calendar and cycle life testing. Commercial aviation is also moving toward greater integration of lithium-ion batteries.

Update Information

- Togo large capacity lithium battery pack

- Lithium battery pack has a string of small capacity

- Large capacity 26650 lithium battery pack

- Discharge capacity of lithium battery pack

- Large capacity explosion-proof lithium battery pack

- Italian Milan 36v lithium battery pack

- 11V lithium battery pack

- Indian lithium battery pack processing

- BOSCH 18V 4A lithium battery pack

- 11ov500A lithium battery pack price

- Lithium battery pack error

- What do the lithium battery pack labels mean

- Helsinki lithium battery pack series connection

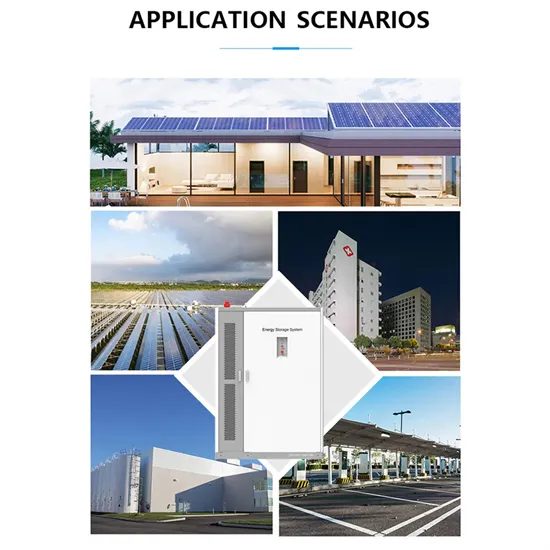

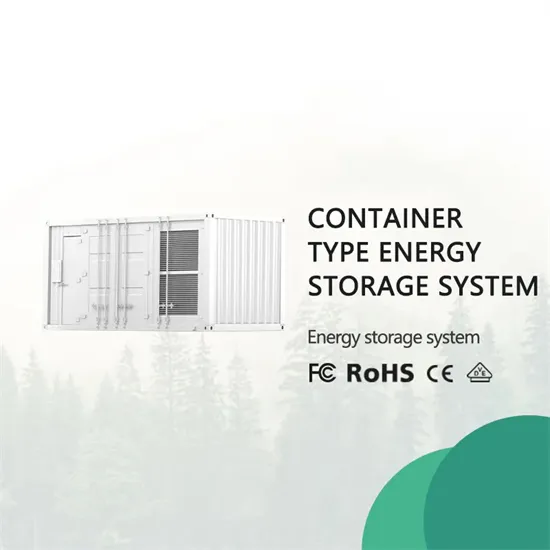

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

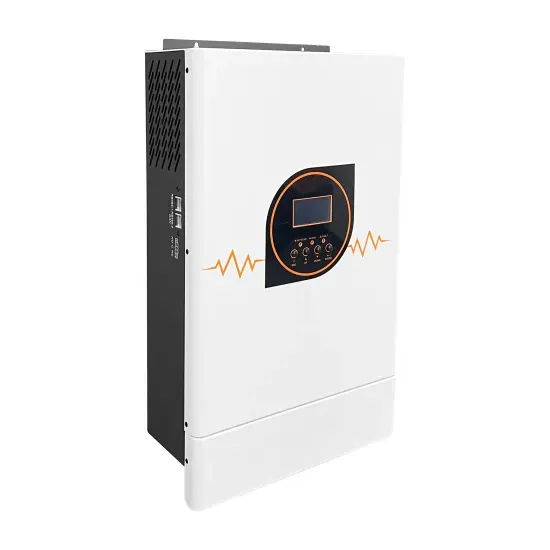

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.