Double-glass PV modules with silicone encapsulation

May 21, 2024 · ABSTRACT Double-glass PV modules are emerging as a technology which can deliver excellent performance and excellent durability at a competitive cost. In this paper a

Towards very low-cost mass production of thin-film silicon photovoltaic

Apr 28, 2006 · Production volume of PV modules increases at > 35% per year, but one is yet far from making a global impact on energy supply. One of the obstacles is given by the present

Global and China Photovoltaic Glass

May 21, 2019 · 7.15.3 PV Glass Business Classification of PV Glass Application of PV Glass in Crystalline Silicon Battery Module A ppli cati on of PV Gl ass i n Thi n-fil m B att ery M od ul e

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Glass/glass photovoltaic module reliability and

Aug 3, 2021 · Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with

This Is How PV Bill of Materials Impacts Module Production

Aug 13, 2024 · In Part 1, we explored the first four key components of the PV Bill of Materials (BOM): electroplated diamond wires, silver paste, PV glass, and encapsulants. Now, in Part 2,

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The growing solar photovoltaic (PV) installations have raised concerns about the life cycle carbon impact of PV manufacturing. While silicon PV modules share a similar framed

Performances of typical photovoltaic module production

Apr 1, 2024 · Considering the amount of each component of a PV module and the availability of database data, this study considers the production of the following main components:

Glass needs for a growing photovoltaics industry

Jan 1, 2015 · • As module prices decline, glass makes an even higher fraction of the PV module cost. • Without new glass production PV industry could experience shortage within 20 years. •

Assessing the sustainability of solar photovoltaics: the case of glass

Sep 12, 2024 · The life cycles of glass–glass (GG) and standard (STD) solar photovoltaic (PV) panels, consisting of stages from the production of feedstock to solar PV panel utilization, are

Global and China Photovoltaic Glass

May 21, 2019 · With production technology barriers broken in 2006, Chinese PV glass companies led by Xinyi Solar Holdings Limited has been pressing ahead with construction of PV glass

Assessment of long term reliability of photovoltaic glass–glass modules

Apr 1, 2015 · Quantifying the reliability of photovoltaic (PV) modules is essential for consistent electrical performance and achieving long operational lifetimes.

Huge PV Glass Project Goes Live in China, Paving the Way

May 13, 2025 · It features 20 base plate production lines and 16 solar panel and backsheet production lines, utilising world-leading ultra-thin photovoltaic calendering technology and

Experimental repair technique for glass defects of glass-glass

Aug 1, 2023 · Solar photovoltaic (PV) energy is a crucial supply technology in the envisioned renewable energy system. With enormous amounts of PV modules being installed, some will

Advancements in Photovoltaic Glass Technology

Aug 19, 2025 · Implementing PV glass technology requires careful planning, financial investment, and a willingness to adapt to new ways of operating. It is through collaboration, knowledge

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · This chapter examines the fundamental role of glass materials in photovoltaic (PV) technologies, emphasizing their structural, optical, and spectral conversion properties that

6 FAQs about [Production of photovoltaic module glass]

What is the production process of Photovoltaic Glass?

Production process of photovoltaic glass The deep processing process of photovoltaic glass involves two steps: tempering and coating. The original sheet is ground and then tempered to obtain tempered sheets, or tempered and coated to obtain coated sheets for component packaging.

Are glass-glass PV modules a good choice?

Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet (a). Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life.

What is Photovoltaic Glass?

At present, the mainstream product of photovoltaic glass is low-iron tempered patterned glass (also known as tempered suede glass) with a thickness of 3.2mm or 4mm.

Is glass/glass photovoltaic (G/G) module construction becoming more popular?

Yes Glass/glass (G/G) photovoltaic (PV) module construction is quickly rising in popularity due to increased demand for bifacial PV modules, with additional applications for thin-film and building-integrated PV technologies.

What if the PV industry doesn't have new glass production plants?

Thousands of new glass manufacturing plants needed for the growing PV industry. As module prices decline, glass makes an even higher fraction of the PV module cost. Without new glass production PV industry could experience shortage within 20 years. Shortage of glass production could drive up the cost especially of thin-film modules.

What is a G/G PV module?

The G/G construction contains a sheet of glass on each side of the PV module, replacing the opaque polymer backsheet traditionally used in conventional glass/backsheet (G/B) modules (figure 1) [7, 8]. The glass provides better mechanical support and improved moisture impermeability over polymer backsheets .

Update Information

- N Djamena polycrystalline photovoltaic module glass

- Latest news on photovoltaic glass mass production

- Tunisia double glass photovoltaic module price

- There are several types of photovoltaic module glass

- Photovoltaic glass production plant in Mauritania

- Solar photovoltaic module production stopped

- Photovoltaic 2 5mm glass production

- Photovoltaic glass substrate production rate

- Photovoltaic glass production company in Valparaiso Chile

- Kinshasa double glass photovoltaic module price

- Tuvalu double glass photovoltaic module manufacturer

- Glass photovoltaic module installation angle

- German environmentally friendly photovoltaic glass production

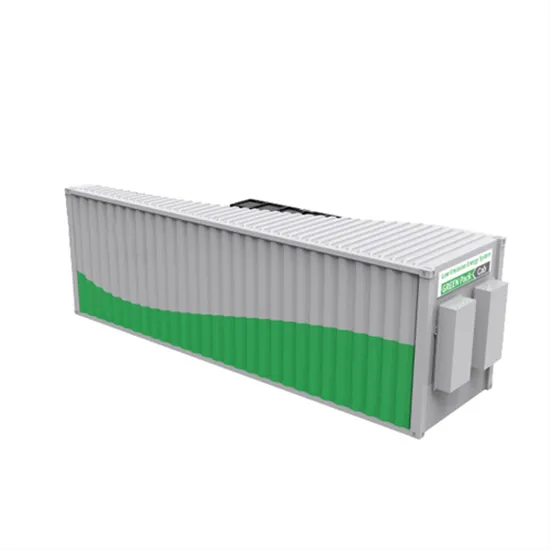

Solar Storage Container Market Growth

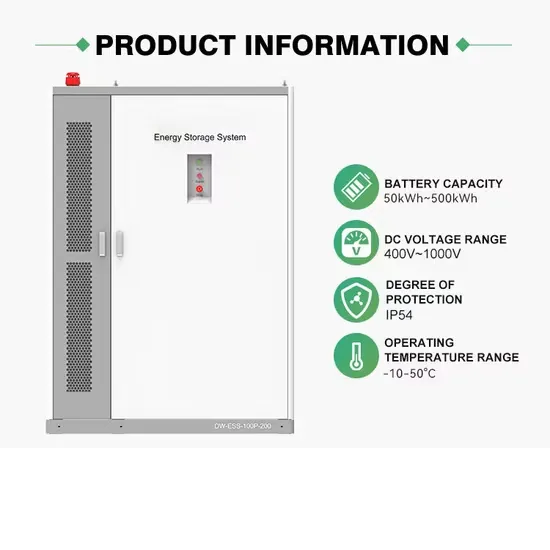

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

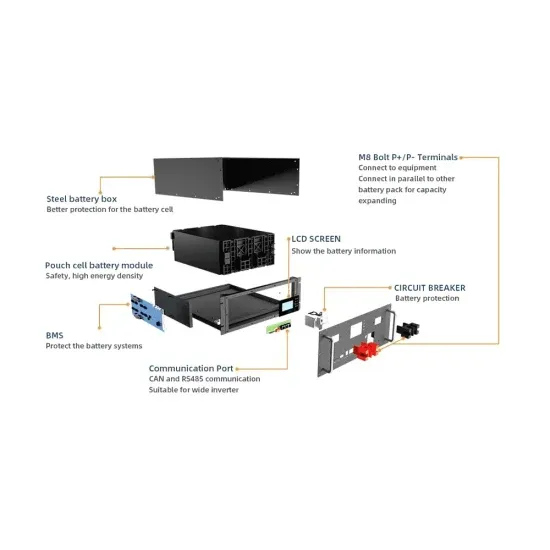

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.