Good News — NorthGlass Achieved Stable Quantity Production

Jan 30, 2024 · The stable production of 1.6mm semi-tempered photovoltaic glass will promote the development of the photovoltaic industry in a more efficient and environmentally friendly

Environmentally Friendly Production

Jun 28, 2025 · The WIRTGEN GROUP''s brand headquarters in Germany and its local production facilities in Brazil, China and India are among the most advanced of their kind. Eco-friendly

Environmentally friendly photovoltaic glass research and

Here, we review the current research to create environmentally friendly glasses and to add new features to the cover glass used in silicon solar panels, such as anti-reflection, self-cleaning,

A comparative life cycle assessment of silicon PV modules:

Sep 15, 2021 · Life Cycle Assessments (LCA) of single-crystalline silicon (sc-Si) photovoltaic (PV) systems often disregard novel module designs (e.g. glass-glass modules) and the fast pace of

Recent Facts about Photovoltaics in Germany

Jun 23, 2025 · These include PV panels and PV tiles for pitched roofs, lightweight PV systems for roofs with low load-bearing capacity, PV systems for green roofs, PV modules for cold façades

New third party life cycle assessment reveals minimal carbon

Dec 10, 2018 · A new study commissioned by solar energy technology leader Midsummer shows that the company''s proprietary flexible CIGS thin film solar module manufacturing process is

Environmentally sustainable methodology for the extraction

Jun 15, 2025 · We demonstrated an efficient and environmentally friendly extraction method for the extraction of the thick layer of EVA-adhered intact glass after dismantled from module by

Global Solar Photovoltaic Glass Market Size, Share

The global solar photovoltaic glass market is expected to experience growth due to increasing demand for renewable energy and rising investment in the production of photovoltaic (PV)

European Glass-Glass Photovoltaic Modules Are Particularly Climate-Friendly

Sep 24, 2021 · Overall, the study results show that the CO 2 emissions for glass-foil modules (glass-glass modules) are 810 (750) in China, 580 (520) in Germany and 480 (420) kilograms

AGC Glass Europe and photovoltaic recycling pioneer ROSI

Jul 22, 2025 · Through this collaboration, AGC Glass Europe and ROSI aim to recycle and reuse high volumes of photovoltaic glass in the production of flat glass. This not only provides

THE RECOVERY OF GLASS AND SILICON FROM

Dec 3, 2024 · Engineering Faculty, "Lucian Blaga" University of Sibiu ABSTRACT: The implementation of photovoltaic (PV) panels has seen significant growth in recent years,

Sustainable Solar: Recycling Photovoltaic Panels for a

Feb 5, 2025 · This thorough assessment highlights the importance of sustainable recycling in tackling the end-of-life challenges of PV panels, which helps in creating a more

Schott powers German glass plants with green electricity

Feb 5, 2025 · Schott aims to achieve climate-neutral production by 2030; a key step is transitioning production from gas to electricity sourced from renewables such as photovoltaics

Solar Glass, a building-integrated photovoltaic technology:

Mar 2, 2025 · Figure 3: Glass-Backsheet vs Glass-Glass PV Module [2] It should therefore be encouraged to build PV manufacturing chain in Europe due to the reduced CO2 emissions and

European glass-glass PV modules particularly climate-friendly

Sep 24, 2021 · Researchers at the Fraunhofer ISE have calculated that silicon photovoltaic modules manufactured in the EU produce 40 per cent less CO2 emissions than modules

Type of the Paper (Article

Feb 5, 2025 · 1. Introduction Photovoltaic (PV) panels, praised for their environmentally friendly energy produc-tion, pose a growing problem for the environment. The rapid expansion of the

Sustainability is close to our hearts | PSL GmbH

Glass consists mostly of quartz sand and lime, which gives the glass its durability. These raw materials are sufficiently available in nature and are even mined directly in Germany and

Managing photovoltaic Waste: Sustainable solutions and

Nov 15, 2024 · The global shift to clean energy has resulted in a significant increase in photovoltaic (PV) panel installations. However, with their limited lifespan

Glass washing challenges in thin-film Glass washing

May 21, 2024 · Introduction: the role of glass in thin-film photovoltaics While classic PV modules are produced in a production process of several steps by wiring crystalline silicon wafers, in

Using PV Installations to Achieve Green Goals | Glass Magazine

Jun 9, 2025 · How PV works As a specialist in oversized glass, sedak has set several targets for 2023 to take steps towards even more environmentally friendly production, like creating

PV Glass: The Future of Sustainable Energy and Design

Jul 15, 2025 · Discover the innovative PV glass technology that combines renewable energy production with stunning architectural design. Learn about its benefits and applications for a

AGC Glass Europe and photovoltaic recycling pioneer ROSI

Jul 22, 2025 · By drawing on AGC Glass Europe''s extensive glassmaking experience and ROSI''s expertise in transforming end-of-life photovoltaic modules into high-purity raw materials, this

Environmentally Friendly Production

May 31, 2025 · The WIRTGEN GROUP''s brand headquarters in Germany and its local production facilities in Brazil, China, and India are among the most advanced of their kind.

SolarGlas AG Builds The First Float Glass Furnace 100

Dec 10, 2007 · Therefore, this furnace will produce solar glass in the most environmentally friendly way for the application in "green" products. Technology partners of SolarGlas AG are the

6 FAQs about [German environmentally friendly photovoltaic glass production]

Are glass-glass PV modules a good choice?

Glass-glass PV modules (b) do not require an aluminum frame and therefore have a lower carbon footprint than PV modules with backsheet (a). Although photovoltaic modules convert sunlight into electricity without producing emissions, PV-generated solar energy does produce CO2 emissions during production, transport and at the end of module life.

Can a photovoltaic system be installed in a European location?

"If I want to install a photovoltaic system in a European location with average irradiation values, I have a great influence on its climate friendliness with the choice of my PV modules," explains Dr. Holger Neuhaus, Head of Department for Module Technology at Fraunhofer ISE.

Do glass-glass solar panels reduce emissions?

In the process, they also found that glass-glass modules enable an additional emissions reduction ranging between 7.5 to 12.5 percent compared to PV modules with backsheet films, regardless of their production location.

Why should glass and photovoltaic panels be partnered?

This not only provides necessary raw material for the glass industry, but also reduces the end-of-life environmental impact of photovoltaic panels. The collaboration marks a great milestone in the journey towards creating a more sustainable and circular glass and photovoltaic value chain.

Do silicon photovoltaic modules produce less CO2?

In a new study, researchers at the Fraunhofer ISE have calculated that silicon photovoltaic modules manufactured in the European Union produce 40 percent less CO2 than modules manufactured in China.

Can Photovoltaic Glass be recycled?

Photovoltaic glass is very transparent and clean, making it a valuable source of recycled material for our factories. However, it has a different composition from our standard products, meaning technical innovation is mandatory to allow for recycling within our processes.

Update Information

- Panama environmentally friendly photovoltaic glass research and development

- Production of photovoltaic glass panels

- Photovoltaic glass production and assembly

- Environmentally friendly photovoltaic curtain wall system

- Is tin used in the production of photovoltaic glass

- Photovoltaic glass substrate production rate

- Photovoltaic glass production company in Valparaiso Chile

- Production of photovoltaic module glass

- Photovoltaic industry glass production stopped

- Curtain wall photovoltaic glass production

- The second largest photovoltaic glass

- Photovoltaic container production method

- Mongolia 300W photovoltaic glass

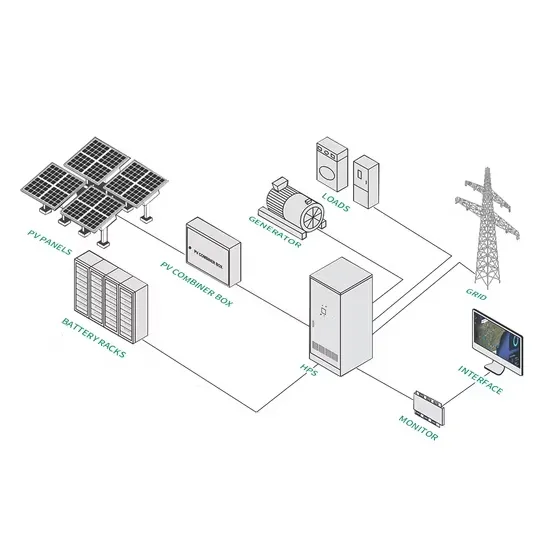

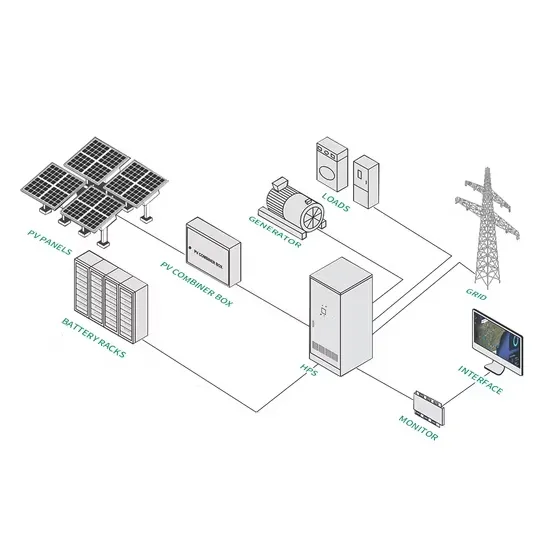

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

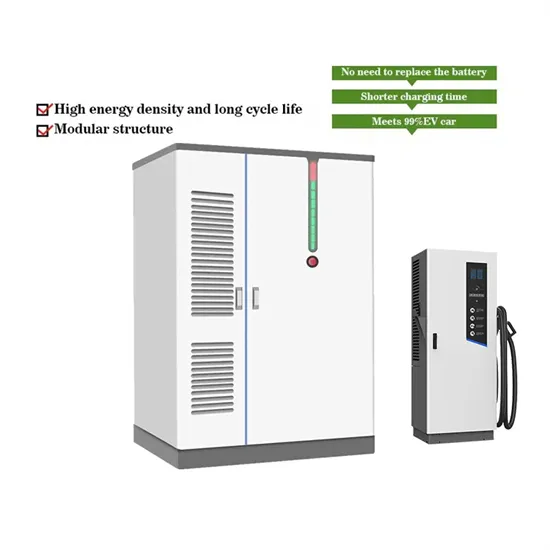

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.