PV Module Automation Production Line

Sunic Solar offers specialized equipment for solar energy production and fully automated production Line solution. We tailor factory layout, equipment configuration, and productionline

Solar Electric System Design, Operation and Installation

Nov 24, 2009 · Messenger, Roger A. and Jerry Ventre, "Photovoltaic Systems Engineering", Second Edition, CRC Press, New York, NY 2004 An engineering text with practical information

Topologies for large scale photovoltaic power plants

Jun 1, 2016 · The concern of increasing renewable energy penetration into the grid together with the reduction of prices of photovoltaic solar panels during the last decade have enabled the

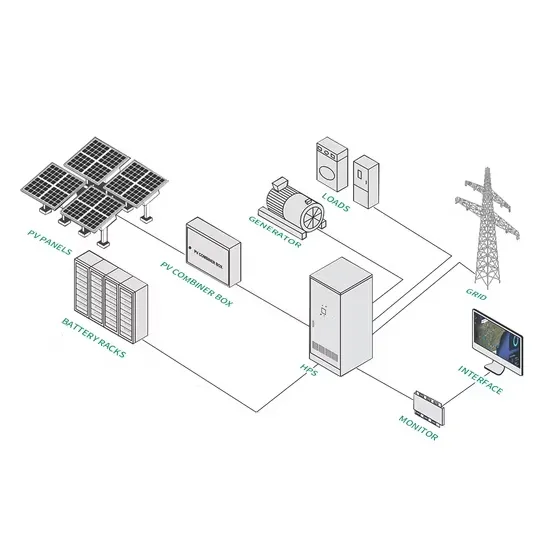

The Ultimate Guide to Understanding Pv System Diagrams

Learn about the PV system diagram and how solar panels convert sunlight into electricity. Understand the components involved in a solar photovoltaic system and how they work

How to Design a Solar PV System: A Comprehensive Guide

Designing a solar photovoltaic (PV) system can be a rewarding endeavor, both environmentally and financially. As the demand for renewable energy sources rises, so does the interest in

Free Solar Sales Software | Design Layouts | Energy Modeling

In five clicks you can create a solar design regardless of skill level. Estimate size, energy production, and cost in seconds. Rely and learn from satellite imagery, equipment and weather

Photovoltaic panel construction drawing design

Provide an architectural drawing and riser diagram for the homeowner showing the planned location for future photovoltaic and solar hot water system components. Space requirements

Solar Photovoltaic (PV) Manufacturing Expansions in the

Apr 1, 2021 · Solar Photovoltaic (PV) Manufacturing Expansions in the United States, 2017–2019: Motives, Challenges, Opportunities, and Policy Context

Cost and CO2 reductions of solar photovoltaic power generation in China

Nov 1, 2014 · To improve the understanding of the cost and benefit of photovoltaic (PV) power generation in China, we analyze the per kWh cost, fossil energy replac

BIM-BASED PHOTOVOLTAIC POWER STATION

Sep 4, 2020 · Abstract: This paper presented an area filling algorithm for automatic layout of photovoltaic power stations and a ray detection algorithm for shadow analysis. The functions

Solar panel production equipment and machinery

Oct 28, 2016 · To the machinery and solar panel production equipment are then added a series of services provided by the equipment supplier, such as training activities prior to delivery of the

Photovoltaic systems

Feb 25, 2016 · The output of a PV module depends on sunlight intensity and cell temperature; therefore components that condition the DC (direct current) output and deliver it to batteries,

Spatial layout optimization for solar photovoltaic (PV) panel

May 1, 2020 · How to make the best use of a solar photovoltaic (PV) system has received much attention in recent years. Integrating geographic information systems (GIS), this paper

Layout Optimization for Photovoltaic Panels in Solar Power

Dec 21, 2023 · Photovoltaic (PV) technology is one of the most popular means of renewable generation, whose applications range from commercial and residential buildings to industrial

Automation solutions for the photovoltaic industry

Jul 1, 2023 · The methodology answers three key questions in photovoltaic plant design: how many photovoltaic modules can be installed?, what is the optimal mounting system

Solar Panel Layout Secrets That Boost Energy

Feb 7, 2025 · Optimize solar array performance by calculating precise inter-row spacing ratios based on latitude-specific sun angles, preventing energy losses

Optimal design and cost analysis of single-axis tracking photovoltaic

Jul 1, 2023 · The methodology was demonstrated in detail for a Spanish photovoltaic plant (Granjera photovoltaic power plant), including the optimal layout of the mounting systems and

Solar PV systems design and monitoring

Jan 1, 2020 · A solar photovoltaic (PV) system includes the main components of PV modules, a solar inverter, and a bias of system (BoS), which can generate AC and DC power. However,

6 FAQs about [Photovoltaic automatic layout components and prices]

What is the optimal layout of single-axis solar trackers in large-scale PV plants?

The optimal layout of single-axis solar trackers in large-scale PV plants. A detailed analysis of the design of the inter-row spacing and operating periods. The optimal layout of the mounting systems increases the amount of energy by 91%. Also has the best levelised cost of energy efficiency, 1.09.

How are P V solar modules arranged?

The P V modules are represented by rectangles inside the mounting system. The packing scheme consists of placing rows of solar trackers to the North–South direction, with dimensions W × L inside the available land area P (see Fig. 9.a).

Which mounting system configuration is best for commercial photovoltaic plants?

The mounting system configuration used in the optimal layout is the one with the best levelised cost of energy efficiency, 1.09. The presented optimisation methodology can be utilised to facilitate the optimal design of commercial photovoltaic plants with single-axis trackers.

What percentage of solar power is generated by P V modules?

As the discount rates are country-specific , and the country is the same in this study, the same r can be considered (0.05%). The electrical power generated by the P V modules in a photovoltaic plant depends mainly on the incident solar irradiance, and P V cell temperature.

What are the design variables of a single-axis photovoltaic plant?

This paper presents an optimisation methodology that takes into account the most important design variables of single-axis photovoltaic plants, including irregular land shape, size and configuration of the mounting system, row spacing, and operating periods (for backtracking mode, limited range of motion, and normal tracking mode).

What size solar cell is compatible with Yili PV?

Compatible cell size: 156-210mm. uses an advanced and high-accuracy six-axis robot combined with a high-efficiency automatic solar string layup system independently developed by YiLi Pv to meet customers’ automatic layout needs for different solar cell strings. At the same time, it has a highly cost-effective advantage. 1.

Update Information

- Photovoltaic module prices in Kathmandu

- Venezuela solar panel photovoltaic power generation prices

- Prices of photovoltaic panels and auxiliary materials

- Praia automatic solar photovoltaic panel production equipment

- Andorra photovoltaic module prices

- Layout of photovoltaic inverter and combiner box bridge

- Transparent photovoltaic panels and prices

- Prices of p-type and n-type photovoltaic modules

- Ghana photovoltaic module prices

- Monocrystalline photovoltaic panel components

- Prices of photovoltaic panels on rural roofs in South America

- Photovoltaic panel prices in Mauritius

- 250w and 300w photovoltaic panel prices

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.