Photovoltaic panels solar energy auxiliary materials

Is solar photovoltaic technology a viable option for energy storage? In recent years,solar photovoltaic technology has experienced significant advances in both materials and

Price of auxiliary materials for solar panels

PV Auxiliary Materials: Cost Reduction and Benefits Increase Since 2023, prices within the PV industry chain have continued to decline, leading to reduced investment costs for downstream

PHOTOVOLTAIC MODULE AUXILIARY MATERIAL LIST

Price list of photovoltaic energy storage system In the cost table, we have estimated battery costs based on typical battery output as follows: battery power 7kW peak / 5kW continuousfor each

Designing new material for PV : Opportunities for

Apr 27, 2021 · Designing New Materials for Photovoltaics: Opportunities for Lowering Cost and Increasing Performance through Advanced Material Innovations 2021 SReport IEA-PVPS T13

Photovoltaic Module Auxiliary Materials 2025-2033

Jun 5, 2025 · The photovoltaic (PV) module auxiliary materials market is experiencing robust growth, driven by the increasing global demand for solar energy. The market, currently valued

How to calculate the price of photovoltaic panel auxiliary

How to calculate the price of photovoltaic panel auxiliary materials (Actual price Solar panels cost between $8,500 and $30,500 or about $12,700 on average. The price you''''ll pay depends

Photovoltaic Auxiliary Materials Market Report: Strategic

Apr 15, 2025 · The photovoltaic (PV) auxiliary materials market is experiencing robust growth, driven by the increasing global demand for solar energy. The market, estimated at $15 billion

Recent advances in solar photovoltaic materials and

Jul 20, 2023 · Hence, the devel-opment of materials with superior properties, such as higher eficiency, lower cost, and improved durability, can significantly enhance the performance of

Recent advances in solar photovoltaic materials and systems

Jul 17, 2023 · Hence, the development of materials with superior properties, such as higher efficiency, lower cost, and improved durability, can significantly enhance the performance of

Photovoltaic panel auxiliary materials market

There are several motivations for investigating new materials for PV modules. Reducing or replacing expensive materialsis important for the overall economics of module production. For

How much does solar auxiliary materials cost | NenPower

Jul 19, 2024 · The cost of solar auxiliary materials can vary widely depending on several factors such as the type of materials, manufacturer, and market conditions. 1. Genera

Price of auxiliary materials for photovoltaic panel

Jun 27, 2020 · Price of auxiliary materials for photovoltaic panel mounting bracket What are adjustable solar panel mounting brackets? Adjustable solar panel mounting brackets designed

Photovoltaic Module Auxiliary Materials Market

Quick Q&A Table of Contents Infograph Methodology Customized Research What are the primary demand drivers for photovoltaic module auxiliary materials across different global regions?

How to calculate the price of photovoltaic panel auxiliary

Page 1/2 How to calculate the price of photovoltaic panel auxiliary materials (Actual price Solar panels cost between $8,500 and $30,500 or about $12,700 on average. The price you''''ll pay

Designing New Materials for Photovoltaics

In the last decade and longer, photovoltaic module manufacturers have experienced a rapidly growing market along with a dramatic decrease in module prices. Such cost pressures have

Photovoltaic module auxiliary material list

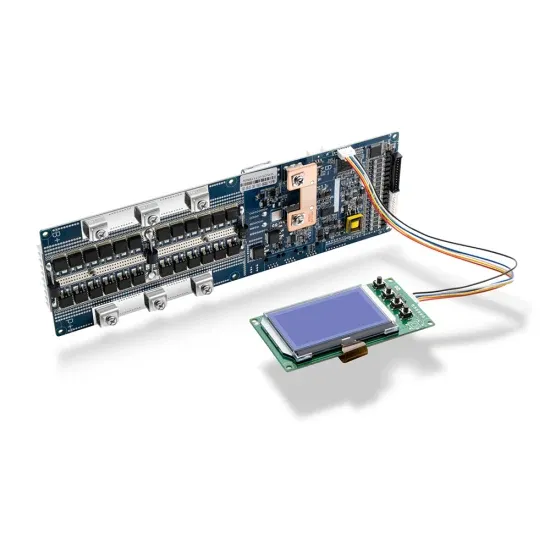

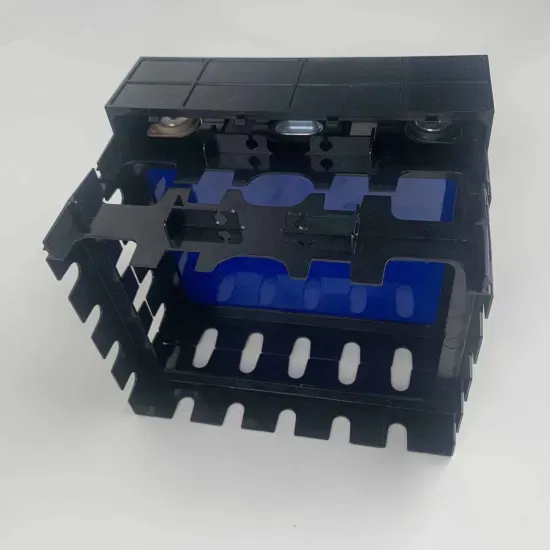

Mar 24, 2023 · From the cost side, the top five auxiliary materials in terms of cost are frame, glass, film, backsheet, and welding tape. The highest percentage of

Photovoltaic Module Auxiliary Materials Market

Evolving trade policies and tariffs dramatically alter cost structures and supply chain dynamics for photovoltaic (PV) module auxiliary material suppliers. Recent U.S. tariffs on Chinese solar

Price trend of photovoltaic circuit board auxiliary materials

About Price trend of photovoltaic circuit board auxiliary materials InfoLink Consulting provides weekly updates on PV spot prices, covering module price, cell price, wafer price, and

Price of photovoltaic brackets and auxiliary materials

Since 2023, prices within the PV Galvanized material photovoltaic bracket material has excellent performance, providing long-lasting durability and a service life of more than 30

How much does solar auxiliary materials cost | NenPower

Jul 19, 2024 · The cost of solar auxiliary materials can vary widely depending on several factors such as the type of materials, manufacturer, and market conditions. 1. Generally, the expenses

What are the manufacturers of raw materials and

May 30, 2024 · Implications for Critical Raw Materials and Ecodesign Analysis of Material Recovery from Silicon Photovoltaic Panels March 2016 EUR 27797 EN. 2 This publication is a

An overview of solar photovoltaic panels'' end-of-life material

Jan 1, 2020 · The natural resources used in manufacturing solar PV panels qualify as auxiliary raw materials within the applicable regulations [9]. However, PV waste must be properly

Photovoltaic panel auxiliary material cost

Here we use the average yearly price for technologies ''''Thin film a-Si/u-Si or Global Price Index (from Q4 2013)''''. 328 PV panels with 40 kW rated power: Stand-alone mode: The auxiliary

PHOTOVOLTAIC MODULE AUXILIARY MATERIAL LIST

Photovoltaic panel assembly quotation list details Many NREL manufacturing cost analyses use a bottom-up modeling approach. The costs of materials, equipment, facilities, energy, and labor

Understanding Photovoltaic Panels Price Trends in China

Dec 30, 2024 · This article delves into the current state of photovoltaic panel prices in China, exploring the factors driving these changes, the technical features of solar panels, and the

6 FAQs about [Prices of photovoltaic panels and auxiliary materials]

Which solar panel and polysilicon pricing report adheres to Iosco reporting requirements?

The only solar panel and polysilicon pricing report that adheres to IOSCO reporting requirements. The OPIS Solar Weekly Report is the first and only solar panel and polysilicon pricing report to follow the International Organization of Securities Commissions’ (IOSCO) requirements for fair and transparent pricing.

How are PV production costs modeled?

The costs of materials, equipment, facilities, energy, and labor associated with each step in the production process are individually modeled. Input data for this analysis method are collected through primary interviews with PV manufacturers and material and equipment suppliers.

What is changing in the solar PV industry?

This in-depth webinar explores the dynamic transformations occurring within the global solar photovoltaic (PV) industry. As geopolitical factors, trade policies, and manufacturing strategies evolve, the landscape of solar PV production and distribution is undergoing significant change. WATCH IT NOW >

What's happening in the solar photovoltaic industry?

On-Demand Webinar This in-depth webinar explores the dynamic transformations occurring within the global solar photovoltaic (PV) industry. As geopolitical factors, trade policies, and manufacturing strategies evolve, the landscape of solar PV production and distribution is undergoing significant change.

How much does non Xinjiang polysilicon cost?

Currently, non-Xinjiang polysilicon with traceability data generally carries a quoted premium of RMB 3–5/kg. Polysilicon prices in dollar terms are prices for polysilicon with non-China origins in dollar terms, not translated from RMB prices.

When will 182mm module price report be based on 182*182-210mm format?

Weekly spot price report for 182mm modules will be based on the 182*182-210mm format from June 2024 onwards due to the slim price gap among varying formats . In India, domestically produced modules will be changed to TOPCon products, and the export price from China will be removed from May 2025.

Update Information

- What auxiliary materials are needed for photovoltaic inverters

- Transparent photovoltaic panels and prices

- Photovoltaic panels and prices in Cape Town

- Small area photovoltaic panels and prices

- Retail prices of photovoltaic panels in the Democratic Republic of Congo

- Prices of photovoltaic panels for industry and commerce in Helsinki

- Prices of photovoltaic panels in Shanghai

- Houses with photovoltaic panels installed on roofs can be sold

- Huawei San Jose photovoltaic panels

- Huawei Benin new photovoltaic panels

- Transparent carbon photovoltaic panels

- How many watts of current does 54 photovoltaic panels have

- Solar photovoltaic panels with batteries

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.