Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · Monocrystalline solar panels work by converting sunlight into electricity through the photovoltaic effect. When sunlight hits the solar panels, the silicon cells absorb the photons

Carport photovoltaic monocrystalline solar panel

Defining Monocrystalline Solar Panels. Monocrystalline solar panels are developed from a single, pure crystal structure, hence the term "mono". The panel is made by cutting a single crystal

What Are The Main Components of Solar Panels?

Mono-Glass Solar Panels: Typically employ 3.2mm fully tempered glass, with a backsheet used on the rear. Dual-Glass Solar Panels: Generally utilize 2.0mm or 1.6mm semi-tempered glass

A Guide to Monocrystalline Solar Panels

Oct 7, 2024 · A Guide to Monocrystalline Solar Panels Monocrystalline solar cells are the most popular option on the market, as well as the most efficient form of solar cell. While they also

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Photovoltaic Accessories Components | SaveDelete

Nov 28, 2022 · Solar panel types For usage in Photovoltaic accessories, there are three common varieties of solar panels: monocrystalline, polycrystalline, and amorphous thin film. There are

Experimental, economic and life cycle assessments of

Mar 15, 2022 · Abstract The utilization of solar technology for clean energy generation has seen a dramatic increase over the past decade. Eyeing the ever-growing solar capacity and the

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

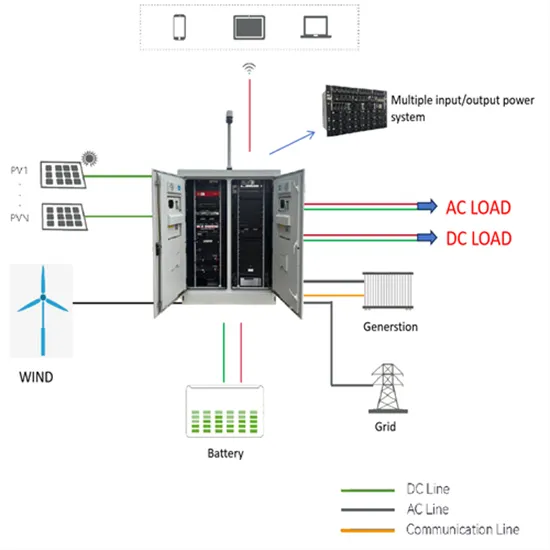

Photovoltaic Basics (Part 2): Integrating the

Sep 30, 2024 · To effectively harness solar energy, it''s essential to understand how to properly configure the components of a system. This article focuses on

100W 12V Flexible Monocrystalline Solar Panel | Renogy Solar

Lightweight, thin, and capable of flexing up to 248 degrees, this Renogy 100W Flexible Solar Panel is your perfect solution for a power-independent journey! IP68 junction box and IP67

Unlocking the Potential of Monocrystalline Solar Modules: A

Monocrystalline solar modules, often recognized by their signature black or dark blue cells, are a pinnacle of photovoltaic technology. Crafted from a single, continuous crystal structure, these

Comprehensive Guide to Monocrystalline Solar

Aug 13, 2025 · Monocrystalline solar panels are photovoltaic cells composed of a single piece of silicon. These cells contain a junction box and electrical cables,

Techno-economic performance comparison of crystalline and thin film PV

Oct 1, 2020 · This investigation compares the financial performance of three different photovoltaic (PV) panel technologies, namely, monocrystalline, polycrystalline and thin film copper indium

6 FAQs about [Monocrystalline photovoltaic panel components]

What are monocrystalline solar panels?

Monocrystalline solar panels are photovoltaic cells composed of a single piece of silicon. These cells contain a junction box and electrical cables, allowing them to capture energy from the sun and convert it into usable electricity. Monocrystalline solar panels are popular for their high efficiency, durability, and relatively low costs.

How does a monocrystalline solar module work?

How Does Monocrystalline Solar Module Work? The working of monocrystalline panels is quite simple and it starts as the sunlight hits the surface of the panel, the photons within the light interact with the silicon atoms in the solar cell which allow electrons to liberate from their atomic bonds.

What is a monocrystalline photovoltaic (PV) cell?

Monocrystalline photovoltaic (PV) cells are made from a single crystal of highly pure silicon, generally crystalline silicon (c-Si). Monocrystalline cells were first developed in the 1950s as first-generation solar cells. The process for making monocrystalline is called the Czochralski process and dates back to 1916.

What are the advantages of monocrystalline solar panels?

Monocrystalline solar panels offer a series of advantages. Thanks to their high degree of silicon purity, they are considered the most efficient. The efficiency rate, which measures the amount of solar energy converted into electrical energy, usually ranges between 12% and 19%.

Why is monocrystalline silicon better than other types of solar panels?

Monocrystalline silicon has a more uniform structure than other silicon types, allowing for better electron flow through the solar cell. This results in a higher power output per square foot of solar panel compared to other types of solar panels.

How to maintain monocrystalline solar panels?

The maintenance required for monocrystalline solar panels is minimal, as they are designed to be durable and resistant to the elements. Cleaning the panels regularly with warm water and a soft cloth will help them perform at optimal levels. However, it is important not to use any abrasive cleaners as these can damage the delicate cells.

Update Information

- Italian monocrystalline photovoltaic panel procurement

- 10w monocrystalline silicon photovoltaic panel

- Photovoltaic panel monocrystalline silicon power

- Libya photovoltaic panel monocrystalline panel manufacturer

- Mongolia monocrystalline photovoltaic panel price

- Photovoltaic panel inverter components

- Monocrystalline silicon photovoltaic panel sample

- Nouakchott Monocrystalline Photovoltaic Panel Company

- India Mumbai Monocrystalline Photovoltaic Panel BESS

- Photovoltaic panel manufacturers direct sales components

- Serbia Monocrystalline Photovoltaic Panel Purchase

- Caracas monocrystalline photovoltaic panel manufacturer

- Norwegian monocrystalline silicon photovoltaic panel manufacturer

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.