800 MW Fully Automatic Production Line for Photovoltaic Panel

Aug 7, 2025 · Ecoprogetti''s production lines are configured to accommodate two primary panel sizes: 2.3×1.4 m for residential use, and 2.5×1.4 m for utility-scale projects. Additionally, our

Solar panels manufacturing machines: our

Oct 28, 2016 · Published: 20 July 2016 2022-> Discover the latest Solar panels'' production & testing machines from Ecoprogetti Srl by clicking here. FROM 20

Edobo solar Photovoltaic (PV) production equipment

Photovoltaic (PV) production equipment refers to the machinery and tools used in the manufacturing process of photovoltaic cells and modules. These equipment are essential for

800 MW Fully Automatic Production Line for Photovoltaic Panel

Aug 7, 2025 · Solar Panel Production: Automated solutions specifically for making high-efficiency solar panels. High Standards: Ecoprogetti''s systems meet strict standards for efficiency and

What equipment is included in the photovoltaic panel

Jan 26, 2024 · The above introduction is a comprehensive production of photovoltaic panels. The entire equipment of the photovoltaic panel production line covers the entire process from raw

Solar Production Equipment

Mar 5, 2025 · In the solar sector, European companies originally played a key role in developing the production equipment needed for the mass production of solar wafers, cells, and modules.

Specialist in Solar Panel Manufacturing Equipment | Horad

Jan 16, 2025 · We offer complete solar panel production lines for global customers to manufacture photovoltaic modules based on their specific requirements. Since foundation, Horad has been

Praia rooftop photovoltaic panel manufacturer

As one of leading solar panel suppliers in China, the Sunrise module solar products currently mainly include the development, production installation, and sales of sunrise pv modules, as

PV Module Testing Machines | Solar Equipment | Horad

Jan 16, 2025 · Our portfolio includes not only automatic solar panel production lines, but also individual equipment for PV modules production, from glass loading equipment at the

4 FAQs about [Praia automatic solar photovoltaic panel production equipment]

What is a high-efficiency automated solar panel production line?

High-Efficiency Automated Solar Panel Production Line Product Overview: Our fully automated solar panel production line integrates cutting-edge photovoltaic panel machinery technology, offering manual operations ranging from 5MW to 15MW and fully automatic turnkey production lines up to 500MW.

Who is Supo solar panel manufacturer?

Powered by dyyseo.com SUPO is a top brand solar panel manufacturing equipment manufacturer from China,export fully automatic solar panel production line,solar panel making machine,solar cell ter stringer,laminator,testing machine and tunrkey line solution,best factory layout plan.

Where can I find the latest solar panels production & testing machines?

Discover the latest Solar panels’ production & testing machines from Ecoprogetti Srl by clicking here. Solar panel production equipment and machinery Nowadays the solar panels’ production equipment is divided into the following required machinery and accessories.

What are the parts of BIPV solar panel production line?

BIPV Line Overview: BIPV Solar panel production line consists of the following parts: (Before lamination)PV glass loading area, EVA loading area, Solar cells stringer, Solar strings layup, manual flow soldering area, EVA and backplane loading area, pre-layer EL inspection and repair area, and conveyor system, Lamination area

Update Information

- Photovoltaic solar panel production in the Netherlands

- Riyadh Solar Photovoltaic Panel Equipment

- Price of automatic photovoltaic panel assembly equipment

- Solar panel photovoltaic panel price

- Solar photovoltaic panel 7v

- Mobile base station equipment solar panel usage fee

- Venezuela solar panel photovoltaic power generation prices

- 6v3w solar photovoltaic panel

- Vatican photovoltaic solar panel manufacturers

- Solar photovoltaic panel parameters i

- 50W Solar Photovoltaic Panel

- Huawei photovoltaic panel equipment

- Solar photovoltaic panel 12 volt 60 amp

Solar Storage Container Market Growth

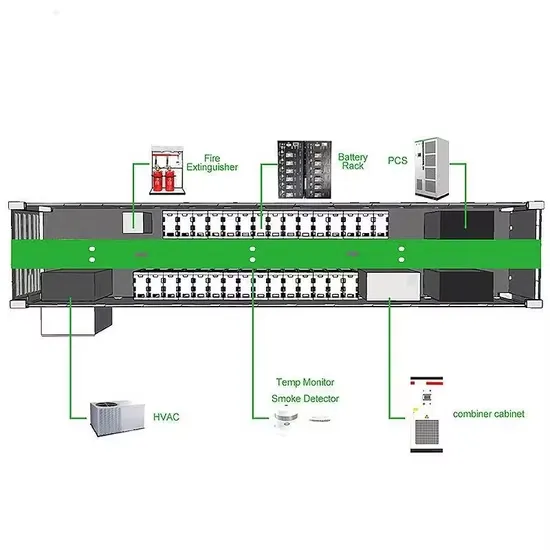

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.