Single-Phase Inverter With Wide Input Voltage and Power

Jan 25, 2019 · This paper proposes a single-phase inverter to achieve high power factor, wide input voltage range, and ripple power decoupling without using large passive components. The

Demystifying high-voltage power electronics for solar

Apr 1, 2023 · Here are the main features of the three inverter configurations: • Micro inverter: ° Integrates a separate inverter and MPP tracker in each solar panel ° No DC cabling, but

Photovoltaic-Powered High-Performance Common-Ground

Mar 1, 2025 · This article answers a critical requirement for switched-capacitor multilevel inverters SCMLI used in renewable energy applications: capability to provide the same sinusoidal

Improved Transformerless PV Inverter for Wide Input‐Voltage

Dec 26, 2024 · Therefore, a boost converter should be inserted between the PV array and the PV inverter (PVI) to boost the voltage of the PV array under SC, but it sustains the full power of

Wide Voltage AC DC Hybrid Maximum Power Output Inverter

Nov 28, 2023 · Get the best {Wide Voltage AC DC Hybrid Maximum Power Output Inverter} at our factory. We ensure superior performance and durability. Shop now for reliable power solutions.

Photovoltaic-Powered High-Performance Common-Ground

Mar 1, 2025 · This article answers a critical requirement for switched-capacitor multilevel inverters SCMLI used in renewable energy applications: capability to provide the s

High Voltage Inverter: Unlocking the Potential of High-Power

Aug 17, 2025 · Generally, a high voltage inverter is a type of inverter voltage that works by converting direct current (DC) into alternating current (AC) at high voltage. This high-voltage

A STUDY ON WIDE BANDGAP SEMICONDUCTORS IN

Feb 17, 2022 · Abstract: The development of new power plants is based on semiconductor materials such as silicon which are widely used in power converters. Wide bandgap, (WBG),

Wide Voltage Input High-Performance Solar Inverter

Wide voltage input high - performance solar inverters have a diverse range of application scenarios, spanning from residential and commercial settings to off - grid and mobile power

Wide Voltage AC DC Hybrid Maximum Power Output Inverter

Dec 20, 2023 · Get the best wide voltage AC DC hybrid maximum power output inverter from our factory. Quality, reliability, and efficiency guaranteed. Order now!

Wide output voltage range LLC resonant converter for 800 V

Feb 3, 2025 · In this paper, a wide voltage gain LLC resonant converter based on topology reconfiguration is proposed. The primary inverter bridge can be configured as a full bridge or a

Single-Phase Inverter With Wide Input Voltage and Power

Jan 25, 2019 · This paper proposes a single-phase inverter to achieve high power factor, wide input voltage range, and ripple power decoupling without using large passive components. The

MIT Open Access Articles A High Frequency Inverter for

Oct 1, 2022 · This paper presents a high-frequency inverter system that can directly drive widely-varying load impedances with high efficiency and fast dynamic response. Based on the

A novel wide input range transformerless PV microinverter

4 days ago · A novel microinverter topology that supports a wide range of input voltage with no floating interval for intermediate capacitance to ensure power decoupling is proposed.

Wide Voltage Input High-Performance Solar Inverter

For recreational vehicles (RVs) and boats, wide voltage input high - performance solar inverters offer a convenient and sustainable power solution. RVs and boats often have limited space for

A review on topology and control strategies of high-power inverters

Feb 15, 2025 · In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency

Analysis of the Working Principle and Application of High Voltage Inverter

May 15, 2024 · With the rapid development of modern industrial technology, high voltage inverter as the core equipment of the power transmission system, in the electric power, petroleum,

Guest editorial: Medium

Aug 3, 2023 · The next generation of power electronic converters and inverters will be expected to exhibit higher power density, improved reliability, increased compactness, greater efficiency,

A New Architecture for High-Frequency Variable-Load

Dec 4, 2023 · Abstract—Efficient generation and delivery of high-frequency (HF, 3-30 MHz) power into variable load impedances is difficult, resulting in HF inverter (or power amplifier) systems

6 FAQs about [Wide voltage and high power inverter]

What is a high-power MV inverter?

In large-scale applications such as PV power plants, "high-power" in medium voltage (MV) inverters is characterized by the use of multilevel inverters to enhance efficiency and scalability. These high-power MV systems generally function within a power range of 0.4 MW–40 MW, and in certain applications, can reach up to 100 MW.

What are the applications of control systems in high-power inverters?

One of the application of control systems in high-power inverters is to increase the speed and accuracy in achieving MPPT. Control algorithms continuously examine the input of the inverter and adjust its operational parameters to extract the maximum available power . Another essential factor is computational complexity.

What is a high power inverter with a NPC topology?

The high-power inverter with a NPC topology, also known as a three-level inverter, is a type of multilevel converter. In contrast to traditional two-level inverters, which have two voltage levels (positive and negative), this inverter has an additional intermediate voltage level known as the neutral point .

Which inverter provides voltage boosting capacity with single SC?

Provide Voltage Boosting Capability with Single SC. A five-level common ground type (5L-CGT) transformer-less inverter with double voltage boosting using eight switches and two capacitors. low-power PV applications and centralized inverter for higher power handling.

Should a boost converter be inserted between PV array and PV inverter?

Therefore, a boost converter should be inserted between the PV array and the PV inverter (PVI) to boost the voltage of the PV array under SC, but it sustains the full power of the PVI under normal conditions (NCs). To address the problem, an improved transformerless PVI with a minimum power processing unit (MPPU) is proposed.

Do multilevel inverters have transformers?

The presence of transformers in multilevel inverters deployed in PV systems, besides increasing size and costs, provides insufficient efficiency. In Ref. , a 5-level voltage source topology is presented, in which an MPC controller is utilized to control the current and voltage of the capacitors.

Update Information

- High voltage power inverter

- High voltage power supply full bridge inverter price

- Processing high voltage inverter

- High Voltage DC Step-Down Inverter

- High voltage inverter sm

- Can t the high voltage of the inverter be adjusted to a lower voltage

- Huawei inverter 5000 watt high power

- High quality off grid solar power inverter Wholesaler

- High voltage cabinet can use UPS uninterruptible power supply

- Shangneng Electric High Power Inverter

- 6 kW high power inverter

- Inverter power AC voltage

- How much does a high power inverter cost

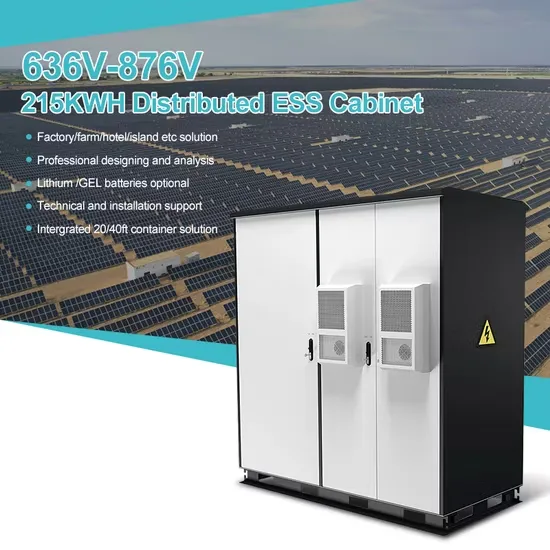

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

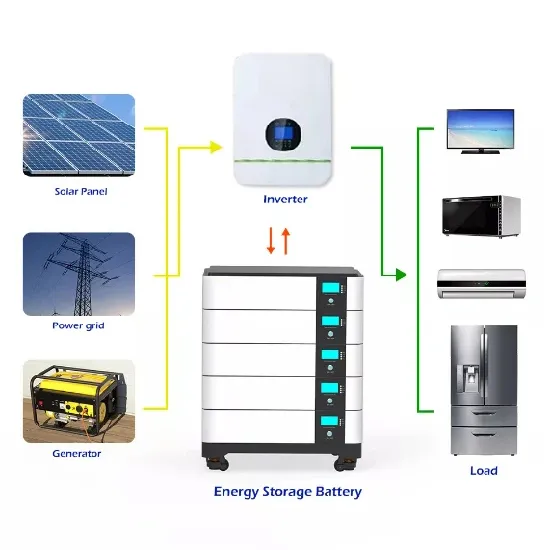

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.