Overview of batteries and battery management for electric

Nov 1, 2022 · Advances in EV batteries and battery management interrelate with government policies and user experiences closely. This article reviews the evolutions and challenges of (i)

Trends in batteries – Global EV Outlook 2023 –

Aug 19, 2025 · The increase in battery demand drives the demand for critical materials. In 2022, lithium demand exceeded supply (as in 2021) despite the

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · Today he serves as chief customer officer for American Battery Solutions, a lithium-ion battery pack manufacturer based in Michigan and Ohio. He is founder and

Lithium Battery Production Process and Key Equipment

Lithium battery packs are the heart of the new energy revolution, and their assembly is a critical process. This article dives into the key stations and equipment that make up a lithium battery

Production requirements of lithium battery PACK

May 27, 2024 · Lithium battery processing, production requirements of lithium battery PACK manufacturers. The process of assembling lithium battery cells into groups is called PACK,

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · , this brochure presents the process chain for the production of battery modules and battery packs. The individual cells are connected in series or parallel in a module. Several

PRODUCTION PROCESS OF BATTERY MODULES AND

Feb 7, 2024 · VDMA The VDMA represents more than 3,700 German and European mechanical and plant engineering companies. The Battery Production specialist department is the point of

Sustainable battery manufacturing in the future

Oct 11, 2023 · Lithium-ion battery manufacturing is energy-intensive, raising concerns about energy consumption and greenhouse gas emissions amid surging global demand. New

Challenges and opportunities for high-quality battery production

Jan 12, 2025 · The rise in battery production faces challenges from manufacturing complexity and sensitivity, causing safety and reliability issues. This Perspective discusses the challenges and

National Blueprint for Lithium Batteries 2021-2030

Jul 1, 2024 · Lithium-based batteries power our daily lives from consumer electronics to national defense. They enable electrification of the transportation sector and provide stationary grid

Comparison of Different Packaging Methods for Lithium-ion Batteries

Lithium-ion batteries are divided into two categories, hard casesoft pack, according to the different s of the cells. The materials of the hard are mainly steel aluminum s, while the soft pack uses

Current and future lithium-ion battery manufacturing

Apr 23, 2021 · Currently, the manufacturing of LIBs still needs to go through slurry mixing, coating, drying, calendering, slitting, vacuum drying, jelly roll fabrication (stacking for pouch cells and

LITHIUM-ION BATTERY CELL PRODUCTION PROCESS

The battery production department focuses on battery production technology. Member companies supply machines, plants, machine components, tools and services in the entire process chain

Advancing lithium-ion battery manufacturing: novel

Jun 15, 2024 · Lithium-ion batteries (LIBs) have attracted significant attention due to their considerable capacity for delivering effective energy storage. As LIBs are the predominant

6 FAQs about [Production of lithium battery pack types]

What is a lithium battery pack?

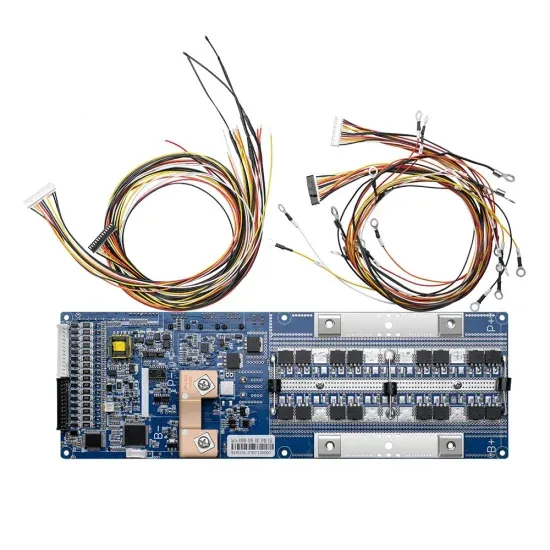

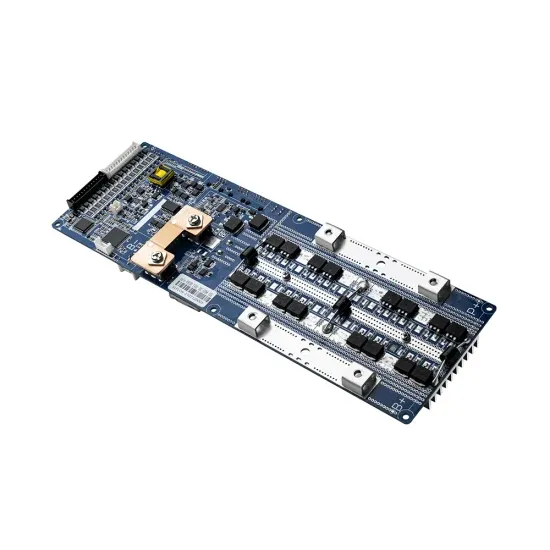

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

How are lithium-ion battery cells made?

Contact us! The production of the lithium-ion battery cell consists of three main process steps: electrode manufacturing, cell assembly and cell finishing.

What are the production processes of a battery pack?

Outer Packaging: Provides physical protection. Output Interfaces: For connecting the battery pack with external devices. Production processes cover cell selection and grouping, welding, assembly, aging testing, inspection, and packaging. Assembly Production Line The process flow of the PACK production line includes:

What is the process chain for the production of battery modules?

, this brochure presents the process chain for the production of battery modules and battery packs. ● The individual cells are connected in series or parallel in a module. Several modules and other electrical, mechanical and thermal components are assembled into a pack. Battery value chain Overview of the production sequence from cell to system

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

Are competencies transferable from the production of lithium-ion battery cells?

In addition, the possible transferability of competencies from the production of lithium-ion battery cells is illuminated. 2ndedition ISBN 978-3-947920-29-7 Ed. PEM of RWTH Aachen University & VDMA

Update Information

- Production of lithium iron phosphate battery pack

- Lithium battery pack production cost

- RV 12v lithium battery pack

- What is MOS for lithium battery pack

- Lithium battery pack has a string of small capacity

- 12 volt power supply with lithium battery pack

- 24v lithium battery pack 8 strings

- The largest lithium battery pack in Slovenia

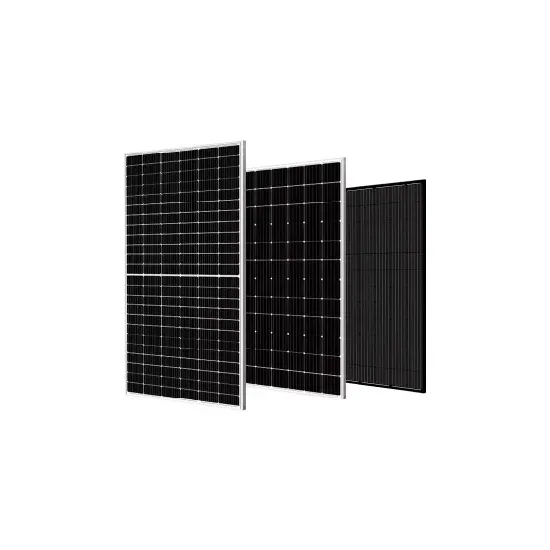

- Riga solar lithium battery pack usage

- 48V lithium battery pack in parallel

- Irish low temperature lithium battery pack

- Saudi Arabia lithium battery pack 3D configuration

- Alofi replaces lithium battery pack

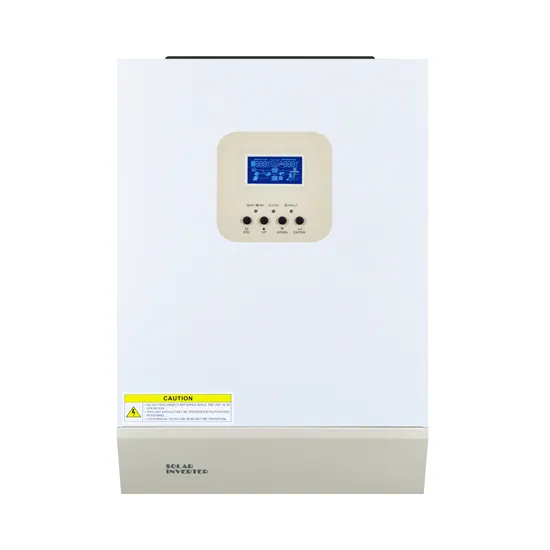

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.