HANDBOOK Primary Lithium Cells (english)

May 5, 2016 · The VARTA Microbattery lithium manganese dioxide cell chemistry was one of the first solid cathode cells commercially developed and is still the most widely used system today.

Heat generation rates and anisotropic thermophysical

Mar 25, 2023 · This paper investigates the variation in the heat generation rates and anisotropic thermophysical properties of cylindrical 18,650 and 21,700 lithium-nickel-manganese-cobalt

Thermal Study of Cylindrical Lithium-Ion Battery at

Jun 28, 2023 · A commercially available 26,650 cylindrical lithium-ion battery was used to simulate battery temperature rise. 26,650 means that the lithium-ion battery has dimensions of

Investigation on thermal management of cylindrical lithium

Aiming to tackle the issues of excessive module temperature and inadequate thermal balance of vehicle power batteries under high discharge rates, a novel interwound cooling belt structure

Thermal Study of Cylindrical Lithium-Ion Battery at

Jun 28, 2023 · This study aims to simulate a commercially available 26,650 lithium-ion battery temperature. The multi-scale, multi-dimensional NTGK model was used to simulate battery

A systematic investigation of thermal and electrochemical

The results showed that increases in the number of battery cells, electrode size, and electrode thickness all led to varying degrees of rise in the internal temperature and its non-uniformity,

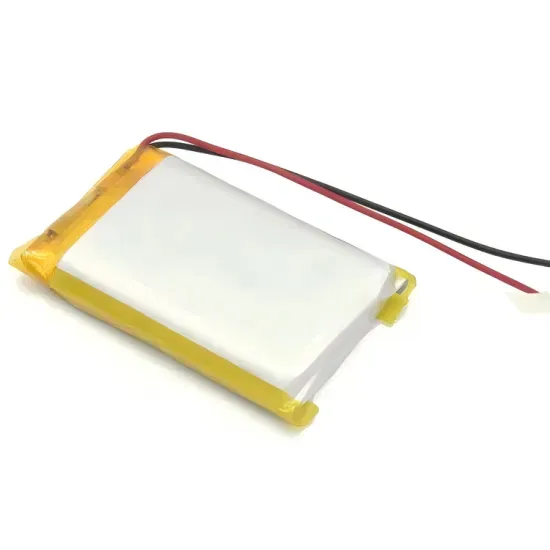

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · What''s the difference between pouch, prismatic, and cylindrical cells in lithium batteries? Read our guide to find the right battery cell type for your system.

Study on the battery thermal management system for cylindrical lithium

Jul 5, 2025 · The maximum temperature of 47 °C is obtained for a pure PCM battery module at a 3 C discharge rate, and it is well matched with experimental results.

Measurement of thermophysical parameters and thermal

Aug 15, 2023 · Cylindrical lithium-ion batteries are widely used due to the advantages of high performance and stable uniformity [1]. When the battery is operating, self-generated heat

Comparison on Thermal Runaway and Critical

Mar 3, 2025 · The thermal hazard results of commercial cylindrical lithium-ion batteries (LIBs) of different sizes from international laboratories are reviewed

Investigation on enhancing thermal performance of the Li-ion battery

Jan 15, 2025 · For the power supply of EVs, Li-ion batteries have emerged as the predominant option due to their impressive attributes, i.e. high-energy density, high power output, and low

Thermal runaway behaviour of a cylindrical lithium-ion battery

Mar 1, 2025 · Lithium-ion batteries (LIBs) may experience thermal runaway (TR) accidents during charge and discharge processes. To ensure the safe operation of batteries, it is very important

Thermal performance of a hybrid thermal management

Battery thermal management systems (BTMS) are crucial for ensuring the safety and performance of Lithium-ion batteries (LIBs). This study proposes a novel hybrid BTMS that integrates phase

ANALYSIS OF THERMAL MANAGEMENT SYSTEM OF

Jun 29, 2022 · Lithium-ion batteries are found suitable for hybrid electric vehicles (HEVs) and clean electric vehicles (EVs), and temperature control for lithium batteries is essential for long

CFD Analysis of Cylindrical Lithium ION Battery Cooling

Jun 2, 2025 · Using aluminum nanoparticles (NPs) as opposed to copper nanoparticles quickly reduced the battery''s maximum temperature by 9.31% [7]. The authors found that increasing

Numerical simulation on the temperature behavior of

May 23, 2024 · The increasing temperature during charge/discharge of Lithium-ion batteries may cause thermal runaway which can lead to a potential factor of igniting a very dangerous

Experimental measurement and modeling of the internal

Dec 1, 2024 · The internal pressure evolution of cylindrical lithium-ion battery cells under abuse tests is evaluated in this work. The pressure evolution is record

ANALYSIS OF THERMAL MANAGEMENT SYSTEM OF

Jun 29, 2022 · Huanwei Xu et al. (2021) developed a proposed development design framework to minimize the maximum temperature difference (MTD) of a car lithium battery pack. First, the

Minimization of Maximum Temperature of Lithium-Ion Batteries

Mar 23, 2025 · Lithium-ion battery pack''s maximum temperature difference (MTD) as well as the average temperature is aimed to improve in this study. Tesla electric car lithium battery pack

Thermal Management of Lithium-Ion Batteries: A

Mar 14, 2025 · This research examines PCM and air cooling systems to enhance battery heat transfer performance. The effects of each system on maximum temperature, minimum

Characterisation of thermal runaway behaviour of cylindrical lithium

Dec 1, 2021 · The maximum temperatures recorded from ARC tests were between 404 and 522 °C, lower than oven tests since some of the battery energy content was released slowly during

Thermal performance of cylindrical lithium-ion battery

Jul 5, 2020 · To overcome the temperature increase of battery along the flow direction of coolant in cylindrical lithium-ion battery module, a composite thermal man

Thermal Performance of a Cylindrical Lithium-Ion Battery

Jun 5, 2024 · The results demonstrated the effectiveness of the cooling system. It was found that the refrigerant-based battery thermal management system could maintain the battery module

Thermal management characteristics of a novel cylindrical lithium

Oct 1, 2024 · To improve the thermal performance of large cylindrical lithium-ion batteries at high discharge rates while considering economy, a novel battery therm

How electrode thicknesses influence performance of cylindrical lithium

Feb 1, 2022 · The effects of the electrode thickness on the energy efficiency and the thermal energy conversion efficiency are quantitatively discussed, respectively. The thermal energy

How to enable large format 4680 cylindrical lithium-ion batteries

Nov 1, 2023 · The demand for large format lithium-ion batteries is increasing, because they can be integrated and controlled easier at a system level. However, increasing the size leads to

Thermal evaluation of lithium-ion batteries: Defining the cylindrical

Oct 1, 2022 · Managing temperatures of lithium-ion cells in battery packs is crucial to ensuring their safe operation. However, thermal information provided on typi

Thermal management of cylindrical lithium-ion battery based

Nov 5, 2019 · To maintain the maximum temperature within the optimum range and to improve the temperature uniformity of cylindrical lithium-ion battery, a liquid cooling method based on the

Numerical simulation of the effect of battery distance and

Jan 1, 2022 · Highlights • Cooling system of a two-dimensional lithium-ion battery pack with 9 battery cells. • Evaluating the pressure drop and temperature of the cooling system. •

A Comparative Study on Prismatic and Cylindrical Lithium-Ion Batteries

Jan 26, 2022 · The study presented concentrates on the thermal performance of prismatic and cylindrical lithium-ion batteries at different discharge rates. Lithium-ion batteries possess the

Study on the battery thermal management system for cylindrical lithium

The operating range of lithium-ion batteries is 25–40 °C, and the temperature difference between the cells in the battery pack should be less than 5 °C 4 – 6. If the temperature of the batteries

Evaluation of cooling effectiveness for cylindrical and

May 26, 2025 · This study investigates the thermal management of cylindrical and prismatic lithium-ion cells under fast discharge rates (2C) using natural air cooling and ester oil-based

Effective cooling and thermal management strategies for cylindrical

Aug 1, 2025 · Abstract This study presents a novel supercritical CO 2 based thermal management system for cylindrical lithium-ion battery packs, leveraging 3D finite volume simulations with

6 FAQs about [Maximum temperature of cylindrical lithium battery]

What is the maximum temperature of a lithium ion battery?

Under composite PCM conditions for a 5 C discharge rate, the maximum battery temperature reaches 46 °C, with a temperature difference of 4 °C 27. Another study included a thorough experimental analysis of a composite phase change material made from expanded graphite and paraffin to manage the thermal state of lithium-ion batteries.

How hot does a lithium ion battery get?

Another study included a thorough experimental analysis of a composite phase change material made from expanded graphite and paraffin to manage the thermal state of lithium-ion batteries. According to the results, the battery temperature drops from 77 °C to 43 °C under 3 C discharging conditions.

How hot is a 26650 lithium-ion battery?

This study aims to simulate a commercially available 26,650 lithium-ion battery temperature. The multi-scale, multi-dimensional NTGK model was used to simulate battery temperature. The highest maximum battery temperature was 346.110 K obtained at 3.0C rate, while the lowest maximum battery temperature of 311.934 K was exhibited at 1.0C rate.

What is the operating range of lithium ion batteries?

The operating range of lithium-ion batteries is 25–40 °C, and the temperature difference between the cells in the battery pack should be less than 5 °C 4, 5, 6. If the temperature of the batteries in the pack exceeds this working range, it can lead to thermal runaway and may even result in the fire and explosion of the battery packs.

What is the maximum battery temperature?

The highest maximum battery temperature was 346.110 K obtained at 3.0C rate, while the lowest maximum battery temperature of 311.934 K was exhibited at 1.0C rate. The highest average battery temperature of 345.164 K and the lowest average battery temperature of 311.627 K were obtained at 3C rate and 1C rate, respectively.

Are lithium-ion batteries compatible with thermal management systems for electric vehicles?

Recent advances in lithium-ion battery integration with thermal management systems for electric vehicles: A summary review. J. Energy Storage 91, 112061 (2024). Shan, S. et al. Numerical investigation of a compact and lightweight thermal management system with axially mounted cooling tubes for cylindrical lithium-ion battery module.

Update Information

- Is the Italian cylindrical battery a lithium battery

- Cylindrical lithium battery sales in Costa Rica

- Togo custom made cylindrical lithium battery

- Amsterdam EK34 cylindrical lithium battery

- 60300 cylindrical lithium battery

- Honiara 10AH cylindrical lithium battery

- Praia lithium battery large cylindrical manufacturer

- Cylindrical lithium battery screening equipment

- BAK cylindrical lithium battery

- Senegal lg lithium battery cylindrical

- Doha energy storage low temperature lithium battery

- Sucre energy storage low temperature lithium battery

- Mobile cylindrical lithium battery

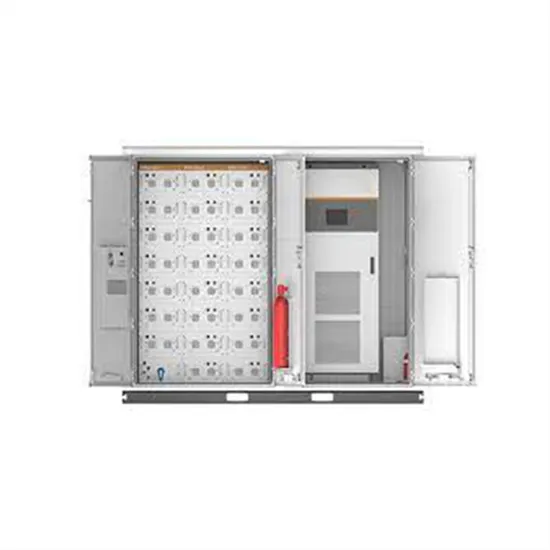

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.