Analysis of Cylindrical Lithium Battery Advantages and

Among all lithium-ion batteries produced globally by lithium battery manufacturers, cylindrical lithium batteries have the highest degree of process standardization and are the earliest to

A Structure of Cylindrical Lithium-ion Batteries

Jul 14, 2016 · Cylindrical Lithium-ion Batteries have been used in many electronic devices. The electrochemical cell of the batteries consists of a layer of positive electrode, a layer of negative

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Meaning of Codes on Lithium Batteries

Lithium batteries are one of the most common components in our daily lives. They allow us to free ourselves from wires and use tools flexibly. Have you ever noticed the numbers printed on

Thermal Model of Cylindrical Lithium-ion Batteries

Jun 10, 2019 · Due to the high energy density, Lithium-ion batteries represent a viable candidate to increase vehicle performances. Much attention has been focused on the thermal behaviour

Thermal evaluation of lithium-ion batteries: Defining the cylindrical

Oct 1, 2022 · Managing temperatures of lithium-ion cells in battery packs is crucial to ensuring their safe operation. However, thermal information provided on typi

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

A Complete Cylindrical Cells Guide: From Basics

Jun 29, 2023 · It''s impossible to think about batteries without first seeing lithium-ion cells as their backbone. These battery cells have always been a top

What are cylindrical lithium batteries and their advantages?

Dec 11, 2023 · 3、 Advantages of cylindrical lithium batteries Compared with soft pack lithium batteries and square lithium batteries, cylindrical lithium batteries have the longest

3V Batteries: The Definitive Guide to Coin Cells

Feb 28, 2024 · In contrast to lithium coin cell batteries, alkaline cylindrical batteries operate on a different chemistry principle but share the common trait

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery

Pouch vs. Prismatic vs. Cylindrical? Your Lithium Battery Cell

Jul 29, 2025 · When selecting a lithium battery for your RV, marine vessel, or off-grid system, it''s not just about the shape of the cells. The format—prismatic, cylindrical, or pouch—directly

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

Cylindrical vs. Prismatic vs. Li-Po Battery: Key

Feb 29, 2024 · Curious about battery types? Learn how cylindrical, prismatic, and lithium polymer batteries stack up against each other. Make the best choice!

How to Understand Cylindrical Cell Batteries

Dec 17, 2024 · Cylindrical cell batteries are a popular choice in various industries due to their high energy density, durability, and versatility. These batteries are commonly used in portable

Cylindrical cell battery

Aug 5, 2025 · Cylindrical cell battery structure Typicalcylindrical cellbattery structure includes: case, cover, positive, negative, 膜片, 电解质, PTC element, gasket, safety valve, ETC.一般来

Everything about Cylindrical Batteries, the Power

May 29, 2024 · The importance of cylindrical batteries is only growing because they are used widely from small electronic devices to EVs. In line with the

[LiFePO4 Battery Types] Cylindrical vs. Prismatic

Oct 22, 2024 · LiFePO4 batteries, or lithium iron phosphate batteries, are increasingly recognized for their remarkable safety, longevity, and versatility.

Analysis of Cylindrical Lithium Battery Advantages and

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · There are many types of cylindrical cells, such as 14650, 17490, 18650, 21700, 26650 and so on. Cylindrical lithium batteries are more prevalent in Japanese and Korean

Power in Cylinders: The Significance of Cylindrical Battery

Feb 21, 2025 · What are cylindrical battery cells? Cylindrical battery cells are a type of rechargeable lithium-ion battery characterized by their cylindrical shape, which resembles a

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium batteries are divided into different systems such as lithium iron phosphate, lithium cobalt oxide, lithium manganese oxide, cobalt manganese hybrid, and ternary

6 FAQs about [Is the Italian cylindrical battery a lithium battery ]

What are the different types of cylindrical lithium batteries?

There are many types of cylindrical cells, such as 14650, 17490, 18650, 21700, 26650 and so on. Cylindrical lithium batteries are more prevalent in Japanese and Korean lithium battery companies, and there are also companies of appropriate scale in China that produce cylindrical lithium batteries. Ⅲ.

Are cylindrical lithium batteries a good choice?

Cylindrical lithium batteries are more suitable for large-volume automated combination production. Large-volume lithium-ion batteries such as electric bicycles and electric motorcycles are basically produced from cylindrical lithium batteries. Not only that, cylindrical lithium batteries are also recognized as green and healthy batteries.

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

What is a cylindrical battery?

This durability is why many industries use cylindrical cells in power tools, electric vehicles, and battery banks that experience rough handling or frequent travel. Prismatic cells (rectangular lithium batteries) are encased in a rigid aluminum or steel shell. The shell provides solid protection for stationary or gently handled applications.

What is a cylindrical lithium ion cell?

The structure of cylindrical lithium-ion cell The round lithium battery refers to the cylindrical lithium-ion cell. The earliest cylindrical lithium-ion cell was the 18650 lithium battery invented by the Japanese company SONY in 1992. Due to the long history of the 18650 cylindrical lithium-ion cell, the popularity of the market is very high.

What is a cylindrical lithium battery used for?

Cylindrical lithium batteries can be used as power sources. In addition, they can also be seen in digital cameras, MP3 players, notebook computers, car starters, power tools, and other portable electronic products. Part 2. Structure of cylindrical battery

Update Information

- The best cylindrical lithium battery cell

- Asuncion cylindrical lithium battery custom manufacturer

- Cylindrical lithium battery assembly parts wholesale

- 3 4v8000ma cylindrical lithium battery

- Difference between Chilean lithium battery and cylindrical battery

- Rwanda cylindrical lithium battery use

- Professional cylindrical lithium battery of different models

- Mobile cylindrical lithium battery

- Cylindrical lithium battery fixing

- Cylindrical lithium battery sales in Costa Rica

- 7cm cylindrical lithium battery

- BAK cylindrical lithium battery

- Cylindrical lithium battery screening equipment

Solar Storage Container Market Growth

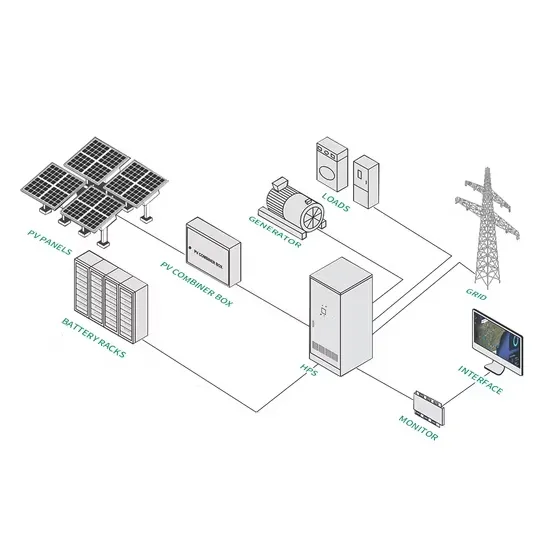

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

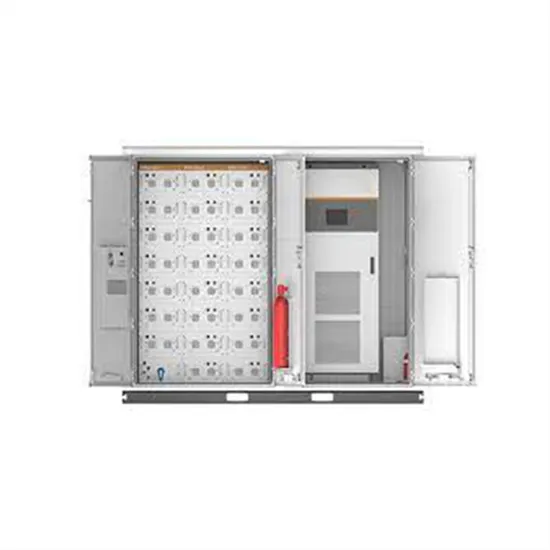

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.