Full Automatic Lithium Battery Recycling Equipment Scrap Cylindrical

Key attributes type battery recycling Power 224.7kw machinery test report Provided video outgoing-inspection Provided warranty 1 Year material other weight (kg) 5000 Product name

Cylindrical Cell Grading Machine for Accurate

Jun 8, 2024 · Cell grading machines, also known as cylindrical cell battery testing machines, are designed with several key features that make them essential for

Safety Analysis of Lithium-Ion Cylindrical

Jan 17, 2024 · In the mass production of cylindrical lithium-ion batteries, end-of-line testing is generally limited to capacity and open circuit voltage tests, which

Lithium Ion Battery (LIB) for X-ray Inspection

Jun 12, 2025 · Matsusada Precision offers X-ray inspection systems of the horizontal irradiation type, ideal for the observation of cylindrical lithium-ion

Full Automatic Lithium Battery Separation and Crushing Equipment

Raw material:Prismatic Battery/ Pouch Battery / Cylindrical Battery;Technology:Crushing/ Vibrating Screening/Air Separation;Advantage:Green and Low-Carbon

Lithium Battery Recycling Equipment Scrap Cylindrical Lithium Battery

The pretreatment process of Electric Car Traction Battery Lithium Ion Battery Recycling Machine mainly comprises the following steps: after discharging the recovered waste batteries,

Quantitative Ultrasound Spectroscopy for Screening

Mar 1, 2024 · Diagnosing lithium-ion battery degradation is a crucial part of managing energy storage systems. Recent research has ex-plored ultrasonic testing for non-invasive health

2000kg/h Lithium Battery Recycling Equipment Scrap Cylindrical Lithium

The waste lithium battery recycling production line mainly includes crushers, sorting equipment, pyrolysis furnaces, leaching systems, and electrolysis devices, which are used for battery

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Batteries A lithium-ion battery contains one or more lithium cells that are electrically connected. Like all batteries, lithium battery cells contain a positive electrode, a

Fast screening of lithium-ion batteries for second use with

Jul 1, 2023 · Fast and accurate screening of retired lithium-ion batteries is critical to an efficient and reliable second use with improved performance consistency, contributing to the

Fully Automatic Cylindrical Lithium Battery Recycling

The waste lithium battery recycling production line mainly includes crushers, sorting equipment, pyrolysis furnaces, leaching systems, and electrolysis devices, which are used for battery

Explosion‑Proof Battery Test Chamber | DHT® Battery Safety

The DHT® Explosion-Proof Battery Test Chamber is a next-generation solution purpose-built for the safety testing of lithium batteries used in electric vehicles (EVs), energy storage systems

Cylindrical Lithium Battery Winding Equipment Market

Jul 23, 2025 · Global Cylindrical Lithium Battery Winding Equipment market was valued at USD 527M in 2024 and is projected to reach USD 1917M by 2032, at a 20.2% CAGR.

6 FAQs about [Cylindrical lithium battery screening equipment]

What is a lithium ion cylindrical cell grading machine?

Lithium-ion cylindrical cell grading machines greatly improve production and quality control for battery manufacturers. They ensure each cell meets precise standards, resulting in consistent quality. By segregating underperforming cells early in production, waste is minimized.

What is a precision battery test system?

The Precision Battery Test System is essential for battery scientists and engineers. We ensure the necessary accuracy and efficiency to streamline the battery test process. The most popular battery tester for coin cell tests High-precision battery test with a test accuracy of ±0.01%FS Designed for pouch cell and cylindrical cell tests

How to ensure optimal performance and lifespan of Li on cylindrical battery cell testers?

To guarantee optimal performance and lifespan of li on cylindrical battery cell testers, certain best practices should be observed. Routine calibration of the machines is essential for maintaining accuracy. Regular cleaning helps prevent dust and debris from impacting sensors.

What are Li-ion batteries used for?

Needless to say, we have catalyzed the widespread application of Li-ion Batteries in consumable electronics, electric vehicles, and energy storage systems. Landt Instruments is a leading supplier of high precision Battery Testing System for battery research and development. Contact us to get a quote.

What is a lithium battery recycling machine?

KERUI Machine’s Lithium Battery Recycling Machine specializes in dismantling and recycling various lithium battery types, including soft package, cellphone, shell, and cylindrical batteries. Each type undergoes a unique recycling procedure tailored to its specific characteristics.

What types of lithium batteries can be recycled?

KERUI Machinery’s lithium battery recycling machine is capable of recycling various types of lithium batteries, including soft package battery, cellphone battery, shell battery, cylindrical battery etc.

Update Information

- Lithium battery assembly cylindrical

- Cylindrical lithium battery core

- Djibouti cylindrical lithium battery module manufacturer

- Azerbaijan cylindrical lithium battery model

- Huawei cylindrical lithium battery extra large

- Professional cylindrical lithium battery of different models

- Brussels cylindrical lithium battery price

- The best cylindrical lithium battery cell

- Papua New Guinea Small Base Station Equipment Lithium Ion Battery Project

- Cylindrical lithium battery 22650

- The smallest cylindrical rechargeable lithium battery

- Difference between Chilean lithium battery and cylindrical battery

- Guatemala cylindrical lithium battery manufacturer

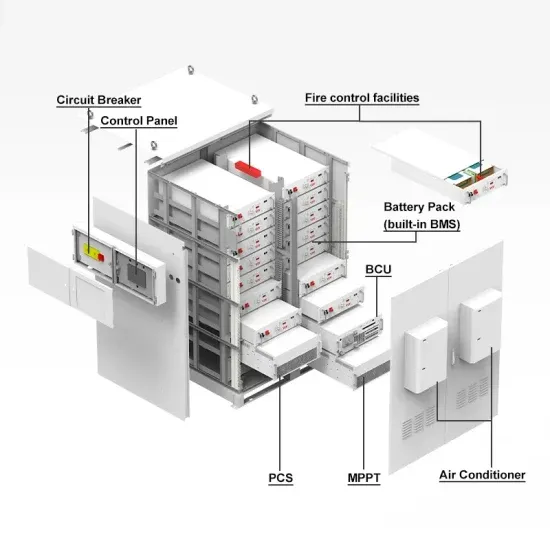

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.