Everything You Need to Know About Cylindrical Batteries

Apr 24, 2025 · Cylindrical batteries can be categorized based on their filler materials into several types: lithium iron phosphate batteries, lithium cobalt oxide batteries, lithium manganese oxide

Analysis of Cylindrical Lithium Battery Advantages and

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

Practical 4.7 V solid-state 18650 cylindrical lithium metal batteries

Jan 17, 2025 · Significantly, our LHCE-GPE allows for the operation of practical solid-state 18650 cylindrical LMBs at 4.7 V and industrial Li-ion batteries at 4.6 V, achieving high energy

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium-ion cells are usually represented by five digits unting from the left,the first and second digits refer to the diameter of

【New message】Innovative Polymer Battery Solutions

Choose GeB for expertly engineered cylindrical lithium batteries that precisely meet your specifications. In a world increasingly reliant on advanced energy storage, the demand for

Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · Herein, we report a sulfide-based cylindrical battery with a significantly reduced operating temperature of 30 °C, enabled by a sulfide solid electrolyte tube, a liquid lithium

Cylindrical lithium ion battery – types,

Aug 4, 2023 · This article provides an overall introduction of cylindrical lithium ion battery, about its different types and different sizes, also the pros and cons.

Lithium-Sulfur Batteries

Aug 19, 2025 · Lithium-Sulfur''s performance is perfect to electrify anything that moves. Lyten has begun the multi-year qualification process for EVs, Trucks, Delivery Vehicles, and Aviation.

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · There are many types of cylindrical cells, such as 14650, 17490, 18650, 21700, 26650 and so on. Cylindrical lithium batteries are more prevalent in Japanese and Korean

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Lithium‐based batteries, history, current status,

Oct 7, 2023 · Currently, the main drivers for developing Li-ion batteries for efficient energy applications include energy density, cost, calendar life, and

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion batteries use lithium in ionic form instead of in solid metallic form and are usually rechargeable, often without needing to remove the battery from the device. They

Cylindrical vs. Prismatic vs. Li-Po Battery: Key

Feb 29, 2024 · Curious about battery types? Learn how cylindrical, prismatic, and lithium polymer batteries stack up against each other. Make the best choice!

Battery Size Chart – SizeChartly

When it comes to powering your devices, choosing the right battery size is crucial for performance and longevity. The correct size ensures efficiency, but selecting the wrong one can lead to

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery

6 FAQs about [Mobile cylindrical lithium battery]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

Are cylindrical lithium-ion batteries a smart choice?

Cylindrical lithium-ion batteries have become a smart choice for several implementations. It can form an energy storage battery pack,store energy from renewable sources like solar and wind. These batteries offer long runtimes, lightweight designs, and high power output.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

Why are cylindrical battery cells so popular?

In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla tabless design. This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680).

Why should you choose a cylindrical lithium ion battery?

They have a long cycle life compared to other rechargeable battery technologies, and cell design ensures better safety features. With its remarkable standardization, the cylindrical lithium ion battery presents an combination of affordability and unwavering quality performance.

How to design cylindrical Li-ion battery cells?

A generic overview of designing cylindrical Li-ion battery cells. Function 1: Two types of jelly roll designs can be distinguished: With tabs and tabless. Jelly rolls with tabs can be realized with a single tab (Design A) or several tabs in a multi-tab design (Design B).

Update Information

- Is the Italian cylindrical battery a lithium battery

- BAK cylindrical lithium battery

- Amsterdam EK34 cylindrical lithium battery

- 60300 cylindrical lithium battery

- Maximum temperature of cylindrical lithium battery

- Cylindrical lithium battery sales in Costa Rica

- Senegal lg lithium battery cylindrical

- Cylindrical lithium battery waterproof

- Mongolian cylindrical lithium battery is a battery

- What is the capacity of cylindrical lithium battery

- Algiers cylindrical power lithium battery with large capacity

- Battery Lithium Cylindrical Battery

- Heterotropic cylindrical lithium battery

Solar Storage Container Market Growth

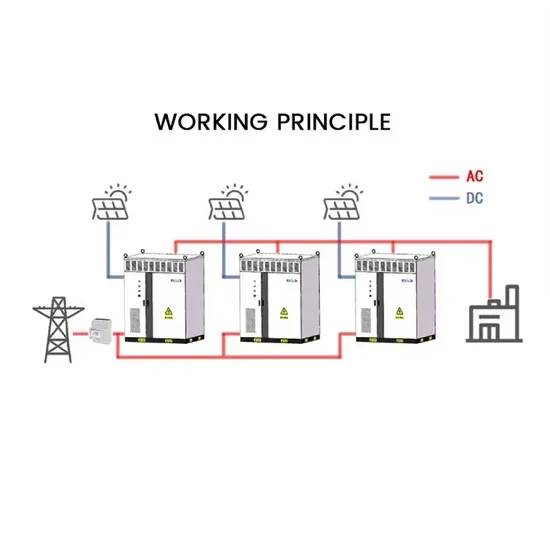

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

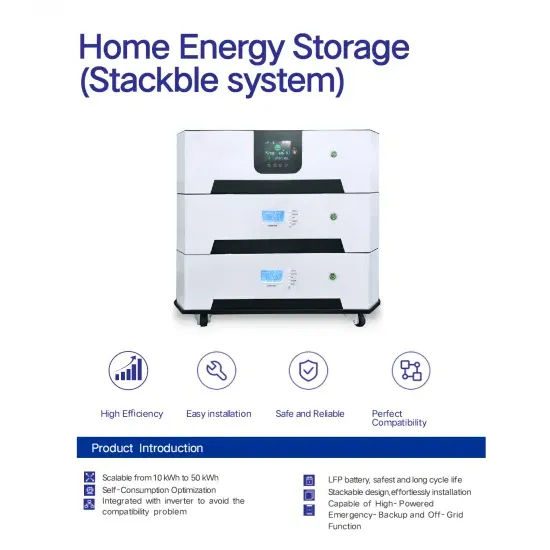

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.