Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · The first three-dimensional distributed coupled electro-thermal equivalent circuit network (ECN) model is developed for a cylindrical lithium-ion battery. The model accounts for

The Handbook of Lithium-Ion Battery Pack Design:

May 16, 2024 · Today he serves as chief customer officer for American Battery Solutions, a lithium-ion battery pack manufacturer based in Michigan and Ohio. He is founder and

Battery Production Flyer: Lithion Ion Cell Production

Feb 7, 2024 · The manufacture of the lithium-ion battery cell comprises the three main process steps of electrode manufacturing, cell assembly and cell finishing. The electrode

A Comprehensive Guide to Cylindrical Lithium

Jul 31, 2025 · Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles,

Investigation on thermal management of cylindrical lithium

Aiming to tackle the issues of excessive module temperature and inadequate thermal balance of vehicle power batteries under high discharge rates, a novel interwound cooling belt structure

Analysis of Cylindrical Lithium Battery Advantages and

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

Development perspectives for lithium-ion battery cell

Dec 5, 2022 · As one central result, the market has witnessed a wide variety of manufacturer- and user-specific cell formats in the past. Standard formats for cylindrical cells were established

Room-temperature cylindrical lithium battery enabled by

Jun 1, 2025 · Herein, we report a sulfide-based cylindrical battery with a significantly reduced operating temperature of 30 °C, enabled by a sulfide solid electrolyte tube, a liquid lithium

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · In this study, we design a loading apparatus capable of precisely measuring the relationship between the loading distance and the contact area between the battery and the

Thermal modelling of cylindrical Lithium-Ion batteries to

Temperature has a profound impact on the performance of lithium-ion batteries. The temperature distribution in the cylindrical cell during charging and discharging cycles is governed by

Practical 4.7 V solid-state 18650 cylindrical lithium metal batteries

Jan 17, 2025 · Practical 4.7 V solid-state 18650 cylindrical lithium metal batteries with in-situ fabricated localized high-concentration polymer electrolytes

Design, Properties, and Manufacturing of Cylindrical Li

Jul 7, 2023 · In the last 3 years, cylindrical cells have gained strong relevance and popularity among automotive manufacturers, mainly driven by innovative cell designs, such as the Tesla

Optimal cell tab design and cooling strategy for cylindrical lithium

Apr 30, 2021 · The ability to correctly predict the behavior of lithium ion batteries is critical for safety, performance, cost and lifetime. Particularly important

Cylindrical Lithium Technologies

6 days ago · Proven battery design, refined materials, special electrolyte solvent, and precise calcination treatment result in a low self-discharge rate during storage. Panasonic Cylindrical

BAK''s big cylindrical battery will support mid-to-high-end EV

Feb 16, 2022 · As the firstly lithium battery company in China to release the 4680 full-tab big cylindrical, BAK''s progress in the research and development of full-tab big cylindrical batteries

BAK Large Cylindrical Batteries: Powering Safer, Smarter E

Jul 22, 2025 · BAK Battery unveils its full-tab cylindrical cell tech & diverse product matrix targeting e-bike safety, performance & cost needs at recent industry summit.

How electrode thicknesses influence performance of cylindrical lithium

Feb 1, 2022 · A design of anode and cathode thicknesses of lithium-ion batteries is a dilemma owing to the facts: 1) increasing the electrodes thicknesses is able t

6 FAQs about [Amsterdam EK34 cylindrical lithium battery]

What is a cylindrical lithium ion battery?

Cylindrical lithium-ion battery cells are a type of rechargeable battery commonly used in a wide range of electronic devices, electric vehicles, and energy storage systems. They are characterized by their cylindrical shape, standardized sizes, and high energy density, making them versatile and suitable for various applications.

What is a comprehensive electro-thermal model for a cylindrical lithium-ion cell?

In this work, a comprehensive electro-thermal model is developed for a cylindrical lithium-ion cell. The model is comprehensively parameterized and validated with experimental data for 2170 cylindrical cells (LG M50T, NMC811), including direct core temperature measurements.

How many Li-ion cylindrical battery cells are there?

This paper investigates 19 Li-ion cylindrical battery cells from four cell manufacturers in four formats (18650, 20700, 21700, and 4680). We aim to systematically capture the design features, such as tab design and quality parameters, such as manufacturing tolerances and generically describe cylindrical cells.

Which lithium-ion batteries have a negative electrode?

Experiments were performed on LG M50T (LG INR21700-M50T) cylindrical lithium-ion batteries. These cells utilise a SiO x-doped graphite negative electrode alongside a LiNi0.8 Mn 0.1 Co 0.1 O 2 (NMC 811) positive electrode, with a nominal capacity of 18.2 Wh (5 Ah).

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

How do you identify a cylindrical lithium-ion battery?

For instance, “65” represents a height of 65mm. Fifth Digit: The fifth digit indicates the cylindrical shape of the cell. Typically, it’s “0” for cylindrical cells. By following this naming convention, we can easily identify the size and shape of cylindrical lithium-ion battery cells.

Update Information

- Cyprus cylindrical lithium battery sales

- The smallest cylindrical rechargeable lithium battery

- Cylindrical lithium battery assembly parts wholesale

- Cylindrical lithium battery 22650

- Marshall Islands cylindrical lithium battery 7260

- Difference between Chilean lithium battery and cylindrical battery

- Lithuania s largest cylindrical lithium battery

- Rwanda cylindrical lithium battery use

- Cylindrical lithium battery fixing

- Cylindrical lithium battery waterproof

- Lithium battery cylindrical to nickel

- Huawei cylindrical lithium battery extra large

- Overcurrent protection of cylindrical lithium battery

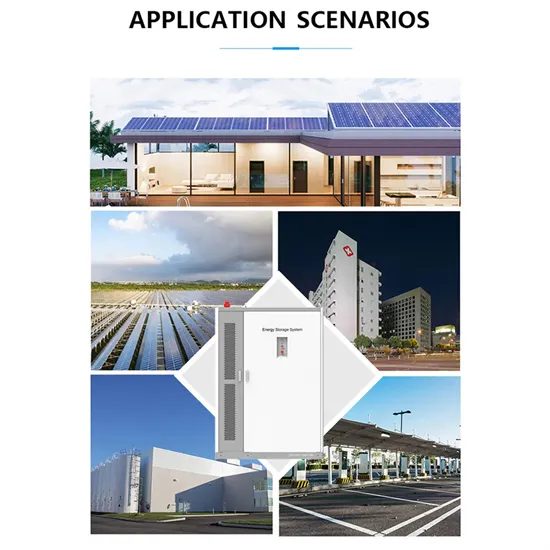

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.