Numbers on Lithium-Ion Battery Shipping Label-News

Oct 29, 2024 · The numbers and symbols on lithium-ion battery shipping labels serve a complex purpose: to encapsulate safety, compliance, and logistical details in a compact format.

Lithium Battery Labels Guide | NS Labels

UN3481 covers lithium-ion batteries packed with or contained in equipment (e.g., a phone, laptop, or tool). These classifications fall under Class 9: Miscellaneous Dangerous Goods, and are

Top 7 Lithium Battery Shipping Label Essentials

Apr 22, 2025 · A lithium battery shipping label is a specialized label for packages containing lithium-ion or lithium-metal batteries. International regulations

Lithium Battery Export: Packaging, Labeling & Safety Guide

Nov 1, 2024 · Lithium batteries or battery packs that comply with the special provisions of Article 188 must be labeled with the "Lithium Battery Handling Label." The external part of lithium -

Lithium Battery Labels 101: A Beginner''s Guide

Jan 22, 2025 · Ensure safe and compliant shipping of lithium batteries with proper labeling. Learn about the requirements and regulations to prevent accidents and ensure safe delivery.

What Are the New CR Lithium Battery Warning Label

Apr 22, 2025 · The updated CR lithium coin battery warning label requirements mandate clearer hazard warnings, child safety symbols, and multilingual text to reduce ingestion risks. These

BU-704b: CAUTION & Overpack Labels

Oct 28, 2021 · All shipments of lithium-based battery products are classified "Dangerous Goods" that must follow these rules: Batteries must be protected against short circuit. (Place in

Mi a lítium akkumulátorok NFPA 704 minősítése?

Jul 31, 2025 · NFPA 704 rating of lithium battery: lithium-ion is 010, lithium metal is 2-3-2. Understand hazard labels and compliance for safe lithium battery storage.

The Complete Guide to CAUTION and Overpack Labeling for Lithium Battery

Jul 30, 2025 · When you ship batteries, you must use caution & overpack labels of lithium battery to comply with IATA Section 11. These labels identify lithium batteries in transit, reduce risks,

What Does the Lithium Battery Mark Mean for Your Devices?

Mar 7, 2025 · The lithium battery mark is a mandatory safety symbol indicating compliance with international transportation regulations. It ensures batteries meet specific testing standards for

Lithium Battery Labels Guide | NS Labels

Lithium batteries power much of the modern world, but when it comes to transport, they present serious risks—particularly fire. That''s why shipments containing lithium-ion batteries fall under

Understanding UN3481 Lithium Ion Batteries: Safety and

Feb 17, 2025 · Proper packaging is essential to meet safety standards. Lithium-ion batteries should be packed in strong, sturdy outer packaging that is capable of withstanding damage

Meaning of Codes on Lithium Batteries

What do the S and P on a lithium battery pack stand for? In short, they represent the series and parallel connection of batteries. For example, a 3s2p lithium battery represents three batteries

6 FAQs about [What do the lithium battery pack labels mean ]

What are lithium battery labels?

Lithium battery labels are like treasure maps. They provide a wealth of information that’s crucial for identifying the battery, ensuring safety, and complying with various regulations. Here’s a breakdown of what you’ll typically find on these labels: Product Information: Basic details about the battery.

What is a lithium battery handling label?

Another required label is the Lithium Battery Handling Label, often seen with shipments classified as UN3481 or UN3091. What it includes: Text that reads: “Caution: Lithium battery.” This label is crucial for alerting handlers about damage, puncture, or overheating risks. It’s also used when batteries are contained in or packed with equipment.

What are the labeling requirements for lithium batteries?

Labeling requirements for lithium batteries are quite strict. They ensure safety and compliance with regulations. Here are some key requirements: Clear and Legible: Labels must be easy to read. If you can’t read the label, it’s useless. So, clarity is crucial. Durable: Labels should withstand handling and environmental conditions.

What are battery warning labels?

Battery warning labels are adhesive indicators on battery packaging specifically designed to alert handlers and consumers about the potential risks associated with batteries. These labels contain hazard information and handling instructions, which are crucial for safe transport, especially for lithium batteries.

What information should be included on a lithium battery label?

The information that should be included on a lithium battery label includes the battery type, capacity, voltage, and any relevant safety warnings or handling instructions. Are there specific regulations for lithium battery labels?

What is a lithium battery hazard label?

These labels contain hazard information and handling instructions, which are crucial for safe transport, especially for lithium batteries. They are designed to be highly visible and resilient, capable of withstanding any environmental conditions that might occur during transportation.

Update Information

- What is the resistance of a lithium battery pack

- What is MOS for lithium battery pack

- What is the charging voltage of a 24V lithium battery pack

- What is the maximum volt of lithium battery pack

- What is the minimum voltage of the 6-series lithium battery pack in China and Europe

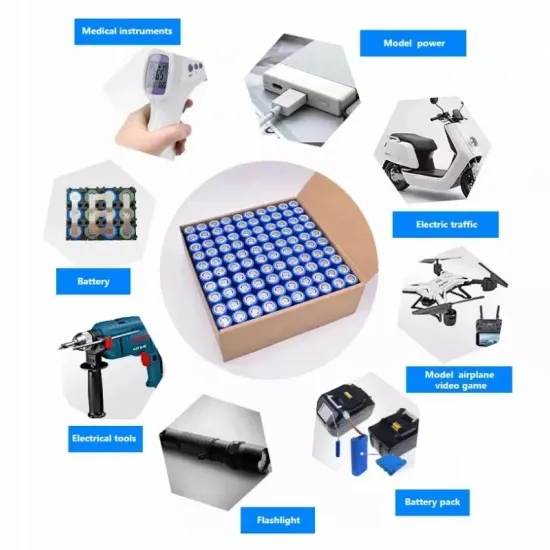

- What equipment will be used for lithium battery pack

- What does lithium battery ESS mean

- Skopje Power Lithium Battery Pack

- What does it mean to connect the inverter to a 12vdc battery

- Nairobi lithium battery pack processing

- Caracas 12v lithium battery pack

- Which 24v lithium battery pack is better

- What is cp in lithium battery energy storage power station

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

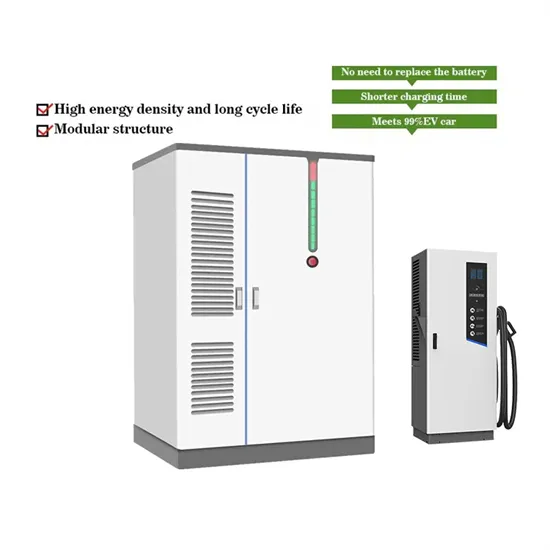

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.