48V Battery Full Charge Voltage Chart: What Matters?

Jun 22, 2025 · The 48V Battery Full Charge Voltage Chart provides a comprehensive overview of the optimal voltage levels for fully charging a 48-volt battery system. Serving as a vital

Lithium Rechargeable Batteries – IBEX Resources

Don''t allow the battery voltage to drop below 3.0V as it can damage the battery. Lithium batteries will often have a specified maximum discharge current of say 2C, which means 2x their mAh

What is the Battery Charge Voltage Limit?

Dec 4, 2023 · Lithium-Ion Batteries: For lithium-ion batteries, the maximum charge voltage is usually 4.2 volts per cell. For example, a 3-cell lithium-ion pack would have a maximum

What is the upper limit capacity of 18650 lithium

Aug 19, 2025 · The voltage of lithium-ion batteries is 3.6V and 4.2V, and the voltage of lithium iron phosphate batteries is 3.2V. The capacity is usually

Lithium-Ion Information Guide | Houston, Texas USA

Lithium-Ion batteries use 3 cells to provide an 11.1 volt battery, 4 cells to provide a 14.8 volts battery or 10 cells to provide 37 volts battery. CAPACITY: Lithium-Ion cells are place in parallel

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · Lithium-ion battery packs are essential power sources used in medical equipment, drones, robots, and countless other devices. These packs are made of multiple Li-ion cells

Battery Voltage Explained: Nominal, Charged, Minimum, and

Feb 17, 2025 · When selecting a lithium-ion battery pack, understanding its voltage characteristics is crucial for ensuring optimal performance and longevity. Three key voltage terms define a

batteries

May 1, 2020 · The jump start pack voltage of 16V + will drop to around the current battery voltage as soon as it is connected. There is good reason to expect it to be safe to use*. 150 W Inverter

A Guide to Understanding Battery Specifications

Dec 18, 2008 · Battery Basics Cell, modules, and packs – Hybrid and electric vehicles have a high voltage battery pack that consists of individual modules and cells organized in series and

Battery pack calculator : Capacity, C-rating, ampere, charge

Battery calculator : calculation of battery pack capacity, c-rate, run-time, charge and discharge current Onlin free battery calculator for any kind of battery : lithium, Alkaline, LiPo, Li-ION,

Lithium-Ion Battery Voltage: How Many Volts And Types

Mar 15, 2025 · A lithium-ion battery has a nominal voltage of 3.7 volts per cell. When connected in series, the total voltage increases by 3.7 volts for each cell. This configuration allows for

What is the maximum voltage of a Lithium Ion Battery

Dec 15, 2014 · The datasheet I''m reading says those batteries (like almost all other Li-Ion battery packs) have a charging voltage of 4.2V +/- 0.05V per cell. So two cell pack would be 8.4V plus

Voltages | Li-Ion & LiPoly Batteries | Adafruit

Jul 29, 2012 · If you want to take your project portable you''ll need a battery pack! For beginners, we suggest alkaline batteries, such as the venerable AA or 9V

Understand Minimum and Maximum Voltage for Lithium Batteries

Apr 8, 2025 · This article will delve into the minimum and maximum voltage levels for lithium batteries and discuss their significance. Lithium batteries have specific voltage limits: the

What Is the Full Charge Voltage for a 48V

Nov 9, 2024 · The full charge voltage for a standard 48V lithium battery, typically configured as a 13-series (13S) lithium-ion battery pack, is approximately 54.6

6 FAQs about [What is the maximum volt of lithium battery pack]

What is the voltage of a lithium ion battery?

Common lithium-ion cells typically have a nominal voltage of about 3.6 to 3.7 volts. This range is standard for most consumer applications, including smartphones and laptops. The actual voltage can vary slightly based on the specific chemistry and design of the cell. Most lithium-ion batteries consist of multiple cells connected in series.

What is a safe voltage for a lithium ion battery?

Lithium-ion batteries function within a certain range at which their voltage operates optimally and safely. The highest range where the fully charged voltage of a lithium-ion battery is approximately 4.2V per cell. The lowest range which is the minimum safe voltage for lithium-ion batteries is approximately 3.0V per cell.

How do I choose a lithium-ion battery pack?

When selecting a lithium-ion battery pack, understanding its voltage characteristics is crucial for ensuring optimal performance and longevity. Three key voltage terms define a battery's operation: Nominal Voltage, Charged Voltage, and Cut-Off Voltage.

What is the nominal voltage of a battery pack?

This value is commonly used to specify battery packs and serves as a general reference for comparing different battery chemistries. For a 3S Li-ion battery pack (three cells in series), the nominal voltage would be 10.8V (3.6V × 3). 2. Charged Voltage: The Maximum Voltage When Fully Charged What Is Charged Voltage?

What should you know about lithium ion batteries?

The most important key parameter you should know in lithium-ion batteries is the nominal voltage. The standard operating voltage of the lithium-ion battery system is called the nominal voltage. For lithium-ion batteries, the nominal voltage is approximately 3.7-volt per cell which is the average voltage during the discharge cycle.

What is the SOC voltage chart for lithium batteries?

The SoC voltage chart for lithium batteries shows the voltage values with respect to SoC percentage. A Li-ion cell when fully charged at 100%SoC can have nearly 4.2V. As it starts to discharge itself, the voltage decreases, and the voltage remains to be 3.7V when the battery is at half charge, ie, 50%SoC.

Update Information

- What do the lithium battery pack labels mean

- What is the minimum voltage of the 6-series lithium battery pack in China and Europe

- 12 volt power supply with lithium battery pack

- What equipment will be used for lithium battery pack

- Lithium titanate battery 12 volt battery pack

- What is the charging voltage of a 24V lithium battery pack

- What is MOS for lithium battery pack

- Nairobi lithium battery pack processing

- Pr3 7v lithium battery pack

- 48v lithium battery pack brand

- Lithium battery pack balance control

- Cook Islands lithium iron phosphate battery pack

- Bolivian lithium battery pack company

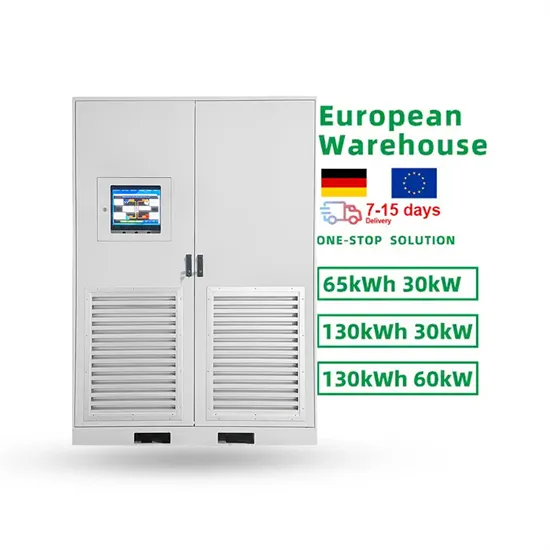

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.