How to Build a Lithium Ion Battery Pack: Expert Guide for

Aug 1, 2025 · What are the key components needed to build a lithium-ion battery pack? The key components include lithium-ion cells (cylindrical, prismatic, or pouch), a battery management

Lithium-ion Battery Pack Manufacturing Process

Jul 28, 2023 · CMB''s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium),

Lithium Battery Pack Introduction to Common Equipment

Jan 30, 2024 · The production process of lithium battery pack involves many equipments, including mixing equipment, coating equipment, winding equipment, hot pressing equipment,

Understanding Lithium Ion Battery Packs: Types, Uses, and

Feb 13, 2025 · Lithium ion batteries have become a fundamental part of our daily lives, powering everything from smartphones to electric vehicles. With the increasing reliance on these

Design approaches for Li-ion battery packs: A review

Dec 20, 2023 · What kind of tools and methods are involved in designing Li-ion batteries? This review paper analyzes the changes and developments in battery design methods investigating

Introduction: What Is a Lithium-Ion Battery Pack?

Jul 4, 2025 · Lithium-ion battery packs are essential power sources used in medical equipment, drones, robots, and countless other devices. These packs are made of multiple Li-ion cells

How to equalization charge Lithium ion battery

Dec 14, 2022 · When the lithium-ion battery pack is produced and stored for a long time, due to the difference in static power consumption of each circuit of

Advanced lithium-ion battery process manufacturing equipment

Jul 18, 2025 · Manufacturing equipment evaluation highlights significant challenges in electrode preparation, cell assembly, and finishing. Using space-saving machinery and cost-effective,

Key Processes and Equipment for Lithium

Nov 29, 2023 · Theoretically, it is difficult for lithium iron phosphate to exceed an energy density of 200Wh/kg. Ternary polymer lithium batteries refer to lithium

Ultimate Guide to Equipment for Lithium Battery Assembly

Jan 23, 2025 · Here are some common types: Electrode Coating Machines: Used to apply active materials onto metal foils. Slitting Machines: Cut coated electrodes into precise widths.

Lithium-Ion Batteries Hazards

Jan 17, 2024 · Hazards Lithium-ion batteries are used in e-mobility devices, consumer electronics, power tools, electric vehicles, and energy storage systems (ESS). They have a higher energy

Battery production equipment and services

Jun 14, 2024 · BATTERY PACK ASSEMBLY and fitting of entire battery factories. Our aim is to offer the manufacturers of lithium-ion batteries a single source of supply for fitting their acilities

Introduction to Production Equipment and Testing Methods for Lithium

Jul 13, 2025 · The production of lithium-ion battery packs requires several key pieces of equipment: Electrode Coating Machines: Used to coat the electrodes with active materials.

Lithium-Ion Battery Pack Manufacturing Process

Jun 4, 2025 · Discover how lithium-ion battery packs are made—sorting, welding, assembly, BMS integration, and testing—to deliver reliable power for EVs,

Fire safety in Lithium-ion battery pack

Jun 13, 2021 · There is a high fire risk related to the storage, processing and use of Lithium-ion batteries. In this article, guest author Neeraj Kumar Singal talks

What Equipment Will Be Used for Lithium Battery Pack

If you''ve ever wondered what equipment will be used for lithium battery pack assembly, you''re not alone. From electric vehicles to grid storage systems, the demand for efficient and safe battery

Lithium Cell Manufacturing Line

Dec 12, 2024 · Lithium Cell Manufacturing Line: Key to Efficient and Scalable Battery Production A lithium cell manufacturing line is a specialized production facility designed to manufacture

How to Assemble a Lithium Battery Pack: Step-by-Step

Feb 9, 2025 · Conclusion Assembling a lithium battery pack requires careful planning, the right tools, and a thorough understanding of series and parallel configurations. By following this

Lithium-ion Battery Safety

Jan 13, 2025 · Lithium-ion Battery Safety Lithium-ion batteries are one type of rechargeable battery technology (other examples include sodium ion and solid state) that supplies power to

6 FAQs about [What equipment will be used for lithium battery pack]

What is a lithium battery pack?

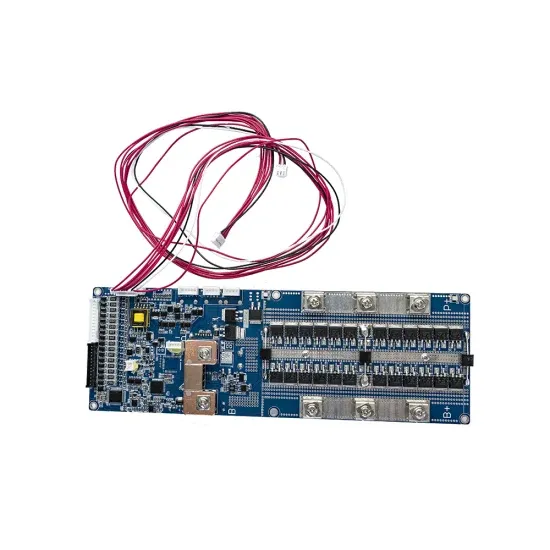

The Lithium Battery PACK line is a crucial part of the lithium battery production process, encompassing cell assembly, battery pack structure design, production processes, and testing and quality control. Here is an overview of the Lithium Battery PACK line: Cell Types Cells are the basic units that make up the battery pack, mainly divided into:

How to contact lithium battery pack engineering team?

Tel & Wechat: (0086) 158 6765 3608 Mr.Pan Our engineering team offers design solutions. The Lithium Battery PACK production line encompasses processes like cell selection, module assembly, integration, aging tests, and quality checks, utilizing equipment such as laser welders, testers, and automated handling systems for efficiency and precision.

How to choose a lithium ion battery?

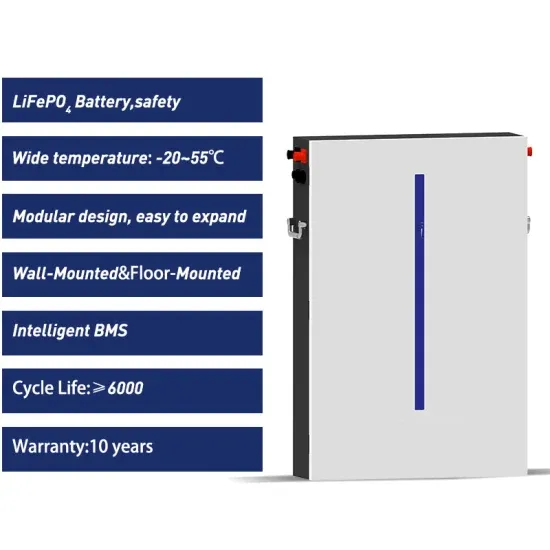

The lithium-ion battery manufacturer should have a strict gap standard of less 5mv voltage gap, less 15mΩ internal resistance, and less 5mAh capacity gap. To ensure the li-ion battery with a long-lasting cycle and reliable performance, the cell sorting process should be very strict.

What is battery pack assembly?

The battery pack assembly is the process of assembling the positive electrode, negative electrode, and diaphragm into a complete battery. This involves placing the electrodes in a cell casing, adding the electrolyte, and sealing the cell.

What is advanced lithium battery pack design?

Advanced Lithium Battery Pack Design: These custom batteries are made when the customer has special requests for temperature capabilities, dimensions, discharge current, and/or battery cycles. In this case, our chemistries, enclosure, and battery management system (BMS) experts are required to monitor each project closely.

Which battery cells are used in a CMB battery pack?

CMB’s battery pack designer gives priority to the following three most common battery cells for the battery pack design: INR (Ternary Lithium), LFP (Lithium Iron Phosphate Chemistry) and LiPo (Lithium Polymer).

Update Information

- Egypt lithium battery pack assembly equipment

- What is MOS for lithium battery pack

- What is the maximum watt inverter that can be used with a 12v 60A lithium battery

- What do the lithium battery pack labels mean

- What is the minimum voltage of the 6-series lithium battery pack in China and Europe

- What is the resistance of a lithium battery pack

- Which lithium battery pack is cheaper in Montenegro

- Hanoi lithium battery pack

- New Delhi special-shaped lithium battery pack

- Tanzania electric sanitation vehicle lithium battery pack

- Bogota 3000-5000mah lithium battery pack

- Huawei Sophia lithium battery energy storage equipment

- Zero cycle battery secondary lithium battery pack

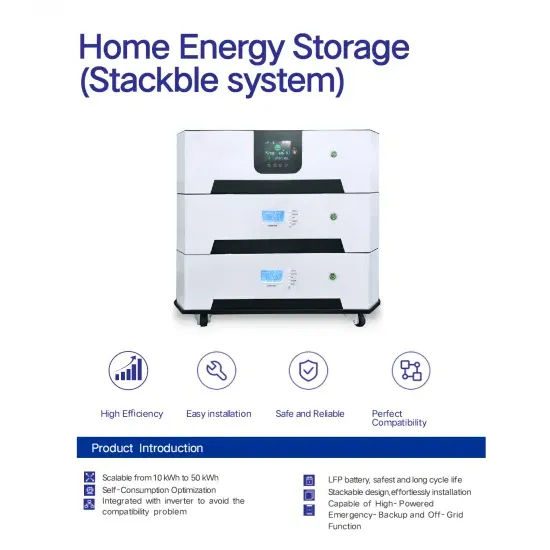

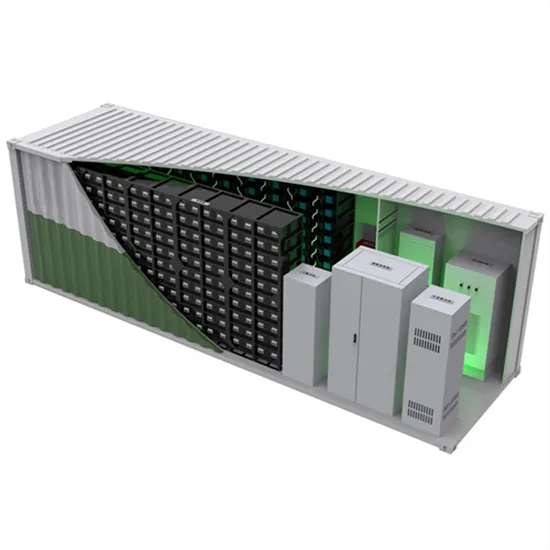

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.