What are double glass solar panels made of? | NenPower

Jun 22, 2024 · 1. MATERIAL COMPOSITION The construction of double glass solar panels involves various materials, each contributing to the overall efficacy and durability of the

EVA or POE, how to choose the encapsulation film of photovoltaic double

May 9, 2022 · At present, POE encapsulation film has almost become the mainstream choice of double glass components. Many owners of double glass power stations have designated POE

Glass Composition, Glass Types

Sep 6, 2011 · Numerous industrial glass compositions and their properties are included in the " High temperature glass melt property database for process modeling ". The glass

Design of additively manufactured glass components for glass

Feb 7, 2025 · Fused silica glass does not require a heated chamber due to its very low coefficient of thermal expansion (Scholze 2012). The disadvantage of processing fused silica glass are

What are the key components of double glazing?

What are the key components of double glazing? The double glazed unit, which slots into a window frame, is made up of a number of components. It includes: A spacer bar – this

(PDF) Design of additively manufactured glass components for glass

Feb 7, 2025 · For the manufacturing of complex glass components, the welding of semi-finished glass products is essential. In the majority of industry, this is realized by operating gas burners

Insulated Glass Units (IGUs): Components and Benefits in

Oct 21, 2023 · In the realm of building construction, where efficiency, sustainability, and aesthetics converge, insulated glass units (IGUs) have emerged as an indispensable component. This

Glass Composition: Key Elements, Types, Uses & Table

The topic of Composition of Glass is important in physics and material science and helps us understand the behavior of materials used in daily life, laboratories, construction, and industry.

How Insulating Glass is Made: A Step-by-Step

Sep 13, 2024 · Insulating glass is made up of two or more glass panes separated by a spacer and sealed to create an airtight unit. This design traps air or gas

Energy-saving performance of respiration-type double-layer glass

Dec 1, 2021 · The development of energy-saving technologies for buildings is an important means of achieving carbon neutrality. The respiration-type double-layer glass curtain wall (RDGCW)

The Typology of the Double Skin Façade System | SpringerLink

Sep 26, 2023 · The double envelope system realizes the diagonal passive ventilation through the integrated and functional constitution of two contiguous components, laterally enclosed by the

Glass structural material of buildings

Jan 6, 2024 · Experiments verifying the actual behaviour of the glass components allow analysing the deformations (deflections) and the ultimate load-carrying capacity, as well as the failure

The Difference Between the Double Glass Photovoltaic

This characteristic makes the double glass components suitable for acid or salt fog larger areas of photovoltaic power station. 9 do not need aluminum frame, double glass components, except

6 FAQs about [Glass material of double glass components]

What is a double glazed insulating glass?

wide variety of insulating glass configurations satisfy a variety of performance and aesthetic requirements. A double-glazed IGU typically consis s of two sheets of glass spaced apart, typically with a hollow aluminium frame that is sealed to both

What is a double glazed window?

The double glazed unit, which slots into a window frame, is made up of a number of components. The cavity – the gap formed between the component parts this can be filled with air or argon gas. Please attach any plans or photos you have. PDF, PNG or JPG under 5mb file size accepted. Maximum of 5 files per form submission.

How is insulating glass made?

Understanding how insulating glass is made will shed light on its benefits and applications. What is Insulating Glass? Insulating glass is made up of two or more glass panes separated by a spacer and sealed to create an airtight unit. This design traps air or gas between the panes, acting as an insulator that reduces heat transfer.

What is DGU glass?

DGU glass or double-glazing units comprise two panes of glass, are separated with a spacer, and filled with argon gas between the two layers of glass. The double-glazed glass suppliers providing dual-glazed glass that easily fits into the window frame comprise seven main components.

What is the composition of glass in Mol%?

Flat panel displays, example glass composition in mol%: Solid oxide fuel cell glass-ceramic seal, example glass composition in mol%: Fused silica glass is pure silicon dioxide (100% SiO2) in the non-crystalline state. It is very difficult to fabricate, so it is the most expensive of all glasses.

What is glass–glass module technology?

In this paper a glass–glass module technology that uses liquid silicone encapsulation is described. The combination of the glass–glass structure and silicone is shown to lead to exceptional durability. The concept enables safe module operation at a system voltage of 1,500V, as well as innovative, low-cost module mounting through pad bonding.

Update Information

- Application scenarios of single and double glass components

- Double glass single glass monocrystalline silicon components

- Solar double glass aluminum alloy components

- Photovoltaic installation of double glass components

- Use double glass components to make a sun room

- Light-transmitting components and double glass

- Mbabane cheap monocrystalline double glass modules

- Photovoltaic module double glass insulation

- Phnom Penh non-standard photovoltaic curtain wall glass components cadmium telluride

- 9BB double glass module

- Amorphous silicon cell double glass module

- Morocco double glass photovoltaic curtain wall customization company

- Double glass module standard

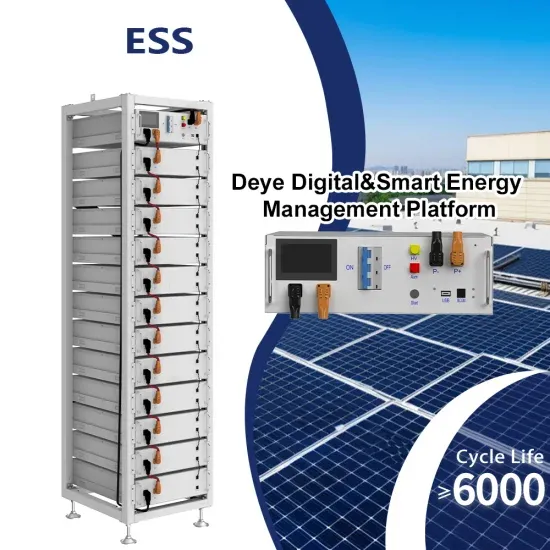

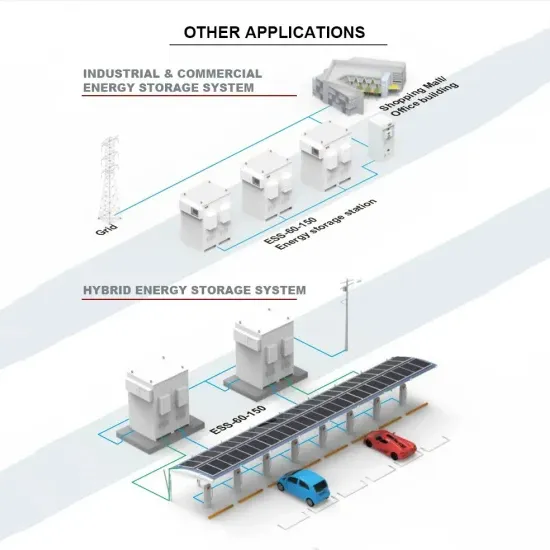

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.