What Scenarios Are Double-Glass Solar Panels Suitable For

Oct 28, 2024 · What scenarios are double-glass solar panels suitable for? With the continuous advancement of technology and the reduction of costs, the application prospects of dual-glass

What is the difference between a double-sided double-glass

May 22, 2025 · The difference between double-sided double-glass n-type monocrystalline solar photovoltaic module and ordinary components is reflected in multiple dimensions, from core

Evaluation of Different Glazing Materials, Strategies, and

Aug 12, 2025 · Covering strategies, such as covers materials as single or double layers, are a crucial technical feature that can significantly affect the heat dynamics and thermal

Verifying a Glass Pane Under Combined In-Plane

Abstract Using glass elements as designated members of the structural design of buildings does not only require conscientious planning of structural redundancies, but also proof of safety for

Evaluating the Performance and Sustainability of Glass

Jan 1, 2023 · Evaluating the Performance and Sustainability of Glass Facade Materials for Office Buildings: A Comparative Analysis of Single and Double-Glazed Glass in Bangladesh

Design Considerations for Laminated Glazing Applications

Nov 18, 2021 · Aesthetic Color Commercial clear float glass is nearly colorless, however, a green or blue-green tint, which is faint in thin glass may become noticeable in glazing applications

What are the application scenarios for single

May 28, 2025 · Yo, what''s up everyone! I''m a supplier of Light Guide Moulds, and today I wanna chat about the application scenarios for single - cavity and multi - cavity light guide moulds. It''s

Advancements in dual-band electrochromic smart windows:

Jul 1, 2024 · Highlights • Overview of the emerging technology of dual-band electrochromic smart windows (DESWs) designed for the independent regulation of visible and near-infrared light. •

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · Canadian Solar''s Dymond double glass module passed 3 times IEC standard test and IEC 61730-2:2016 multiple combination of limit test and obtained VDE report, which fully

Life cycle assessment based optimization of scenarios of reusable glass

Dec 1, 2024 · Reusable glass bottles are experiencing a resurgence, driven notably by societal concerns and regulations. While single-use glass bottles generally have higher environmental

Hybrid Glass Structures – Design Philosophy and

In this paper authors will summarise current design approaches for hybrid glass structures. Our past and present projects will be used to demonstrate how such structures can be justified

Compression performance analysis of hexagonal and re

Apr 1, 2025 · The performance of honeycomb structures is closely related to the shape of the unit cell, and traditional honeycomb structures with a single design often fail to meet the diverse

(PDF) Glass Application in Solar Energy Technology

May 3, 2025 · By incorporating the ASTM-G173-03 solar spectrum and the response of the commercial silicon sensor, this framework quantitatively predicts solar cell performance,

Single and Double Window Sight Glasses and Sight

Oct 13, 2019 · General product information 2.1 Single window and double window sight glasses General description A range of single and double window sight glasses having screwed

Direct Selling Application of Multiple Scenarios Double Insulated Glass

Apr 6, 2025 · Warranty: 5 Years Type: Float Glass Shape: Flat Structure: Hollow Glass Thickness: 4mm, 5mm, 6mm, 8mm, 10mm Air Cavity Depth: 12mm

Current Status And Future Development Trends of Single And Double Glass

Jun 17, 2024 · Looking forward to 2025, since there will still be a significant cost difference between double-glass and single-glass modules, and the water resistance and reliability

Different Types of Glass and Their Application Scenarios

Jan 18, 2025 · 1. Annealed Glass What it is: Float glass is produced in four types: annealed glass, tempered glass, heat-strengthened glass, and laminated glass. Annealed glass is the simplest

6 FAQs about [Application scenarios of single and double glass components]

Are double-glass modules better than single-sided glass panels?

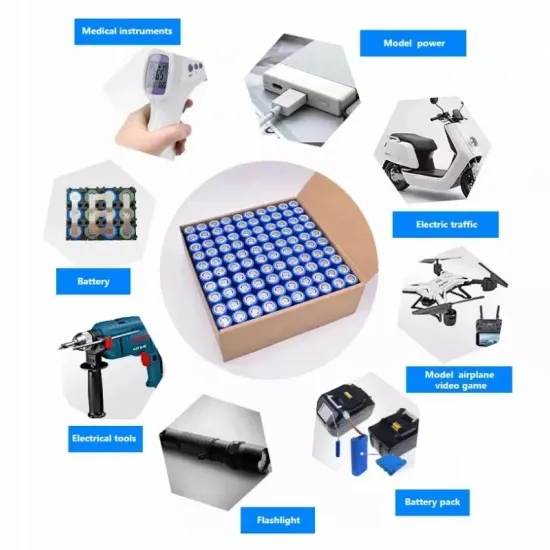

However, advancements in glass technology have mitigated this issue to some extent. Weight: Double-glass modules are generally heavier than single-sided glass panels due to the additional glass layer. Applications: Double-glass modules are well-suited for environments with harsh weather conditions, high humidity, or corrosive elements.

Are double-glass modules better than glass-on-glass?

Aesthetics: Double-glass modules can offer a sleeker appearance due to the glass-on-glass design, which some people find more aesthetically pleasing. Cost: Double-glass modules tend to be more expensive to produce and install due to the added materials and manufacturing complexity.

What is the encapsulation reliability risk of double glass module?

The double glass module is superior to the conventional single glass module, which indicates that the encapsulation reliability risk of double glass module is good without delaminating risk. 90 Jing Tang et al. / Energy Procedia 130 (2017) 87–93 4 J. Tang et al./ Energy Procedia 00 (2017) 000–000 Fig. 3.

Why should you choose a double glass module?

Durability: Double-glass modules are more robust and resistant to environmental stressors, such as moisture, UV radiation, and temperature fluctuations. The dual glass layers provide enhanced protection against physical damage, moisture ingress, and degradation over time.

What is the difference between double-glass solar panels and single-sided solar panels?

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which can impact their durability, performance, and applications. Construction: Double-glass modules consist of two layers of glass sandwiching the solar cells and other components.

What is a single sided glass panel?

Weight: Single-sided glass panels are lighter than double-glass modules, which can be advantageous for certain installation scenarios. Applications: Single-sided glass panels are commonly used in residential and smaller commercial installations where aesthetics and cost-effectiveness are important factors.

Update Information

- High crystal components and single crystal double glass

- Double glass single glass monocrystalline silicon components

- What is the current price of single crystal double glass photovoltaic panels

- Use double glass components to make a sun room

- Solar double glass aluminum alloy components

- 48 pieces of 182 double glass components

- The difference between single glass and double glass

- Photovoltaic installation of double glass components

- Double glass 540 components

- Light-transmitting components and double glass

- Malta double glass photovoltaic curtain wall customization

- Photovoltaic module double glass insulation

- All black single glass module

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.