The Hidden Cost of Poor Quality During PV Module

🔍 The Hidden Cost of Poor Quality During PV Module Manufacturing. In a gigawatt-scale solar factory, poor quality doesn't just mean product defects — it means hidden #financial,

Review of photovoltaic module degradation, field inspection

Sep 1, 2022 · Considering the relevance of photovoltaic technology in the power generation system, degradation and failure of photovoltaic modules are becoming particularly relevant. To

Solar PV Module Quality Concerns Still Exist for Developing

Oct 8, 2013 · Conversations with solar industry executives from across the value chain reveal concerns about low-quality materials being used in the manufacturing of solar modules, and

Nation''s PV growth, exports chase demand

5 days ago · The share of modules exported to European markets now accounts for more than half of the total as demand for PV products in Europe climbs. Demand from Spain, Germany

The 2025 PV Module Manufacturing Quality Report

Mar 20, 2025 · Introduction In 2024, the photovoltaic (PV) module manufacturing market experienced significant changes due to regulatory policy, new facility capacity, cell technology,

India''s solar panel exports surge as world looks

Jan 2, 2025 · India also exported $25 million of photovoltaic cells that were not assembled into modules in April-October FY25 with 90 per cent of the exports

Solar PV Module Quality Risks

Jan 8, 2024 · Damage and Defects Can Occur Throughout the Entire Module Lifecycle. • Many module buyers are procuring from new and inexperienced suppliers due to supply chain

India''s solar module exports to USA to keep

Oct 30, 2023 · The report notes that India''s PV module exports to the USA have grown exponentially recently—16 times (by value) in FY 2023 vis-à-vis FY

SILICON SOLAR MODULE VISUAL INSPECTION GUIDE

Sep 26, 2023 · ABOUT THIS DOCUMENT This document is designed to be used as a guide to visually inspect front-contact poly-crystalline and mono-crystalline silicon solar photovoltaic

China''s Overhaul of Export Tax Rebates to Further Squeeze

Nov 18, 2024 · Last year, Chinese PV makers exported 70.3 gigawatts of silicon wafers, 39.3 GW of solar cells, and 211.7 GW of PV modules, accounting for more than 80 percent of the global

Module quality is suffering as PV producers cut costs

Jun 4, 2025 · ''We''re seeing that manufacturers have tried to remove materials, remove costs from those modules, to cut their losses, and that presents reliability risks,'' says Tristan Erion-Lorico.

Degradation of poor quality photovoltaic panels

Degradation of poor quality photovoltaic panels Uncover the secrets of solar panel longevity! Learn how long solar panels last in Australia, understand the degradation science and

China''s PV Industry Restructuring Begins: Europe Sees a

In the first half of 2024, China exported 94.4 GW of PV modules to Europe, accounting for over 40% of total shipments. However, reports by PV-Tech and Euractiv indicate that several

Assessing the real quality of PV modules

May 21, 2024 · AbSTrACT With new industrial challenges faced by the PV industry – such as the striking development of Chinese manufacturers, and ever more demanding investors and

Poor quality solar photovoltaic panels

rials to ensure reliable, durable, dling. Inferior panel quality. How much efficiency doe a solar panel lose over its lifetime? Solar panels typically degrade at an average rate of about 0 alike,

China Customs PV Export Data Released in April

May 23, 2024 · On May 21, China Customs updated its monthly export data. Firstly, we summarize the PV main material export situation. From January-April 2024, China''s PV main

Poor quality solar photovoltaic panels

The payback performance of a solar PV systems is based, besides FITs and irradiation, on the initial power output, power degradation and the lifetime of the pv module(s). Needless to say

China''s solar PV module exports hit 236 GW in 2024, with

Feb 4, 2025 · China exported 16.63 GW of modules in December 2024, up 9% MoM from 15.2 GW and up 3% YoY from 16.18 GW, according to InfoLink''s customs data. China exported

The 2025 PV Module Manufacturing Quality Report

Mar 20, 2025 · PV module performance, reliability, and safety. Contamination during production can lead to issues such as moisture ingress and mechanical degradation, while poor

Managing photovoltaic Waste: Sustainable solutions and

Nov 15, 2024 · The global shift to clean energy has resulted in a significant increase in photovoltaic (PV) panel installations. However, with their limited lifespan

Photovoltaic Module Export Process and Classification,

Nov 1, 2024 · Disadvantages: Low conversion efficiency, relatively poor stability, short lifespan. High-Efficiency Photovoltaic Modules: Such as heterojunction solar cells, tandem solar cells,

Ensuring Quality in PV Module Manufacturing: Key Insights

In the fast-paced solar energy sector, maintaining high-quality photovoltaic (PV) modules is crucial for long-term performance and reliability. The 2025 PV Module Manufacturing Quality Report

6 FAQs about [Poor quality of exported photovoltaic modules]

How does the US market affect PV module supply?

manage quality for their PV module procurement.Policy changes within the U.S. market significantly impacte PV module supply for buyers and manufacturers. The U.S. saw increased domestic manufacturing capacity, driven by the IRA (Inflation Reduction Act)

What are the disadvantages of PV modules?

PV module performance, reliability, and safety. Contamination during production can lead to issues such as moisture ingress and mechanical degradation, while poor lamination increases the risk of delamination, str ctural instability, and environmental exposure. Glass damage, including scratches, compromises mechanical strength an

How has the photovoltaic module manufacturing market changed in 2024?

61617181818191920212223IntroductionIn 2024, the photovoltaic (PV) module manufacturing market experienced significant changes due to regulatory policy, new facility capacity, cell technology, product design,

What challenges did the PV module industry face in 2023 & 2024?

machines and advanced quality control measures.In 2023 and 2024, the PV module industry faced new challenges due to shifting policies, increased demand for supply chain transparency, and

What is a PV module failure?

The International Energy Agency (IEA) Photovoltaic Power Systems Programme (PVPS) defines the term PV module failure as any effect causing module power degradation which normal operation does not reverse or an effect causing safety issues , .

What are recurring issues in PV module production?

on of recurring issues in PV module production. Defects are non-conformances related to inspection criteria agreed to (or provided by the manufacture as it relates to a buyer’s supply contract. Another significant defect sub-category is “Cell Cracks,” which represent a substantial issue in terms of cell quali

Update Information

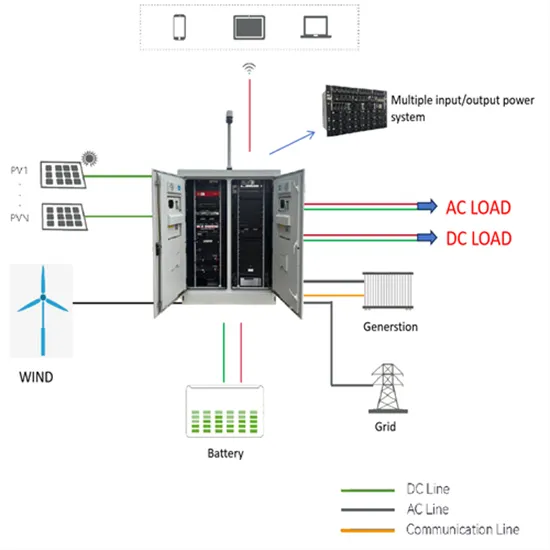

- What are the batteries for photovoltaic modules

- Efficiency comparison between double-glass and single-glass photovoltaic modules

- Photovoltaic inverter quality ranking

- Photovoltaic module quality improvement project

- Degradation rate of photovoltaic monocrystalline silicon modules

- Price and quality of photovoltaic panels

- Disadvantages of glass photovoltaic modules

- Equatorial Guinea photovoltaic cell modules

- Single-sided and double-sided photovoltaic modules

- Black double-glass photovoltaic modules

- Magadan monocrystalline silicon photovoltaic modules

- Spanish high quality photovoltaic folding container wholesale

- Photovoltaic Neighborhood Inverter Quality Comparison

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.