Quality Infrastructure for Photovoltaic Systems

May 16, 2024 · For PV module manufacturing, specific guid-ance is provided in IEC 62941 Terrestrial photovoltaic (PV) modules – Quality system for PV module manufacturing, which

INLINE QUALITY INSPECTION AND SMART PROCESS

Apr 23, 2020 · ls; Allowing reliable forecasting of the performance of PV systems on short and long time scales. This improved technical context will create better access to diverse types of

Future of photovoltaic technologies: A comprehensive review

Oct 1, 2021 · As a result of sustained investment and continual innovation in technology, project financing, and execution, over 100 MW of new photovoltaic (PV) installation is being added to

Enhancing Solar Quality: Key Insights and Recommendations

Sep 8, 2024 · Kiwa''s quality assurance process for solar modules focuses on four key areas - the Product Qualification Program (PQP), Pre-Shipment Inspection (PSI), Batch Testing, and

Power quality analysis of a large grid-tied solar

Jul 1, 2014 · This study presents practical approaches to a grid-connected solar photovoltaic plant with associated control circuits developed in the time

Power quality improvement of grid‐connected solar power

Oct 18, 2024 · Integrate renewable energy system (RES) into grid-connected load system in enhancing reliability and reducing losses. However, integrating these systems introduce power

Global perspectives on advancing photovoltaic system

Jan 1, 2025 · Wang et al. [240] proposed a photovoltaic-thermoelectric hybrid (PV-TEH) system with a dual-function thermoelectric module serving as both a thermoelectric generator and

Module quality is suffering as PV producers cut costs

Jun 4, 2025 · Every new iteration of Kiwa PV Evolution Labs'' (PVEL) Module Reliability Scorecard comes with its share of positive and negative news. On the positive front, for example, 50

VDE SPEC 90038-1 V1.1 (en) "Solar Module Quality Spec"

VDE SPEC 90038-1 (en) has been developed in a project group aiming for a Solar Module Quality Standard (SMQS) and it cannot be granted that all possibly interested parties could have been

13 Reliability and Performance of Photovoltaic Systems

Review of repair methods for PV modules in terms of efficiency and long-term stability. We will examine and discuss current best practices and technical challenges for reliability testing,

Explore Kiwa''s Update PV Module Guidance in "Raising the Bar"

Oct 29, 2024 · Explore Kiwa''s latest white paper, Raising the Bar, developed by PV quality experts Kiwa PVEL and Kiwa PI Berlin. This essential guide dives into quality assurance for

Performance and degradation analysis for long term

Nov 1, 2013 · The factors affecting the performance of PV module, PV module degradation modes, stress factors responsible for degradation, accelerated aging tests and current PV

PowerPoint Presentation

Feb 24, 2023 · Examples of low quality projects Quality Assurance for a Power Plant – TÜV Rheinland approach Examples of low quality modules Product quality of PV modules within

Enhancing grid-connected photovoltaic systems'' power quality

Mar 1, 2025 · This study focuses on enhancing power quality in on-grid photovoltaic (PV) schemes through an innovative dynamic voltage restorer (DVR) that integrates two control

Data Driven Quality Assurance of PV Power Plants

Fraunhofer ISE covers a wide range of digitalization solutions in PV systems, including intelligent PV monitoring, data-driven soiling analysis, digital twinning and PV power forecasting.

Facilitating circularity of end-of-life photovoltaic in China

May 16, 2025 · The rapid growth of global photovoltaic (PV) installation will lead to the emergence of end-of-life (EoL) modules in the coming decades. It is essenti

Solar Quality Assurance and Quality Control (QA/QC)

Nov 12, 2024 · Target customers Applus+ independent quality assurance and quality control PV services are provided to solar plant owners, developers, and EPC companies, and cover the

Review of degradation and failure phenomena in photovoltaic modules

May 1, 2022 · Secondly, a summary of the main stress factors and how they influence module degradation. Finally, a detailed review of degradation and failure modes, which has been

INLINE QUALITY INSPECTION AND SMART PROCESS

Apr 23, 2020 · The system design – one of the key factors for quality installations, can be traced back as the root source of failures which becomes evident in the later stage of a PV project.

The 2025 PV Module Manufacturing Quality Report

Mar 20, 2025 · manage quality for their PV module procurement. Policy changes within the U.S. market significantly impacte. PV module supply for buyers and manufacturers. The U.S. saw

Quality Management Plan for 300kW PV Solar Farm Installation

9. Conclusion The Communication Management Plan outlines the approach for effective communication throughout the installation of the 300kW PV solar farm in a remote village. By

Recent technical approaches for improving energy efficiency

Mar 1, 2023 · Photovoltaic (PV) technology is recognized as a sustainable and environmentally benign solution to today''s energy problems. Recently, PV industry has adopted a constant

Ensuring Quality in PV Module Manufacturing: Key Insights

In the fast-paced solar energy sector, maintaining high-quality photovoltaic (PV) modules is crucial for long-term performance and reliability. The 2025 PV Module Manufacturing Quality Report

A new method to improve the power quality of photovoltaic

Apr 24, 2025 · With the steady annual growth of grid-connected photovoltaic (PV) power generation, the intermittent nature of this energy source has been increasingly drawing

Photovoltaic (PV) Module Technologies: 2020

Nov 2, 2021 · Photovoltaic (PV) module prices are a key metric for PV project development and growth of the PV industry. The general trend of global PV module pricing has been a rapid and

Automated Photovoltaic Module Quality Assessment: Defect

Jun 16, 2023 · To help address the important challenge of photovoltaic module end-of-life (EoL) management, an automated module quality assessment methodology to determine the

Solar Energy Quality Infrastructure in India

Jan 16, 2025 · Executive Summary This report is about the quality of infrastructure (QI) used in renewable energy installations, pertaining specifically to solar PV and solar thermal. The study

6 FAQs about [Photovoltaic module quality improvement project]

How does the US market affect PV module supply?

manage quality for their PV module procurement.Policy changes within the U.S. market significantly impacte PV module supply for buyers and manufacturers. The U.S. saw increased domestic manufacturing capacity, driven by the IRA (Inflation Reduction Act)

How has the photovoltaic module manufacturing market changed in 2024?

61617181818191920212223IntroductionIn 2024, the photovoltaic (PV) module manufacturing market experienced significant changes due to regulatory policy, new facility capacity, cell technology, product design,

What challenges did the PV module industry face in 2023 & 2024?

machines and advanced quality control measures.In 2023 and 2024, the PV module industry faced new challenges due to shifting policies, increased demand for supply chain transparency, and

What are the five fundamental rules for PV module buyers?

on five fundamental rules for PV module buyers:A PV module’s quality is determined by the quality of it component parts and manufacturing consistency.Adequa e testing prevents ailures & underperformance. Warranties do not.Manufacturers set thei own quality standards unless buyers intervene.Tru but verify the quality of deliver-ed modules.

How to manage PV equipment quality?

estors to actively manage PV equipment quality.Through the use of pre-production factory audits, sup-ply chain traceability assessments, production oversight, pre-shipment inspections, and lab testing, buyers must leverage the tools at the

What are recurring issues in PV module production?

on of recurring issues in PV module production. Defects are non-conformances related to inspection criteria agreed to (or provided by the manufacture as it relates to a buyer’s supply contract. Another significant defect sub-category is “Cell Cracks,” which represent a substantial issue in terms of cell quali

Update Information

- Photovoltaic module factory cost reduction and efficiency improvement project

- Sierra Leone Photovoltaic Module Industry Chain Project

- Photovoltaic Module Innovation and Entrepreneurship Project

- Malabo Photovoltaic Module Project

- Double-glass photovoltaic module efficiency improvement

- Photovoltaic module project investment

- Advantages of Photovoltaic Module Project

- Malabo High Efficiency Photovoltaic Module Project

- Chile photovoltaic module project

- Double-glass photovoltaic module manufacturers

- Dili Solar Photovoltaic Module Factory

- Kinshasa double glass photovoltaic module price

- Sukhumi Photovoltaic Glass Base Project

Solar Storage Container Market Growth

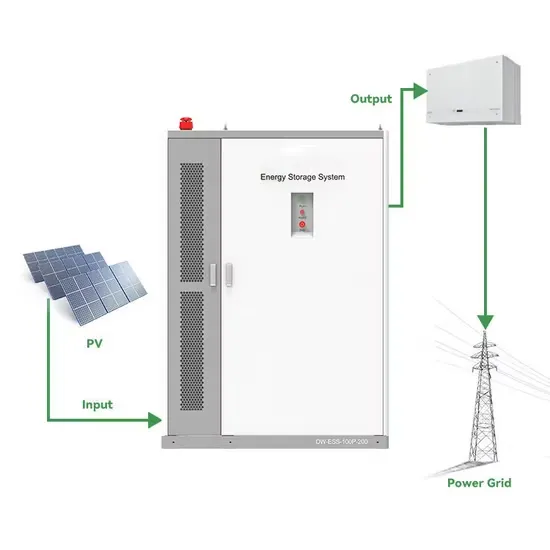

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

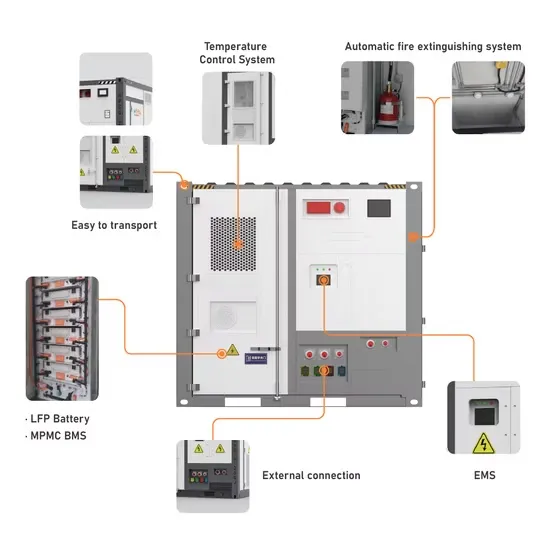

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.