Enhancement of efficiency in monocrystalline silicon

Sep 6, 2024 · As the representative of the first generation of solar cells, crystalline silicon solar cells still dominate the photovoltaic market, including monocrystalline and polycrystalline

Monocrystalline silicon solar energy specifications

Download scientific diagram | Specifications of mono-crystalline silicon PV modules at STC from publication: Modeling a Simple Single-phase Grid-connected Photovoltaic System

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

Experimental, economic and life cycle assessments of

Mar 15, 2022 · Experimental, economic and life cycle assessments of recycling end-of-life monocrystalline silicon photovoltaic modules Mitchell Shyan Wei Lim a, Dong He a, Jasmine

Material intensity and carbon footprint of crystalline silicon module

Feb 1, 2024 · The solar photovoltaics (PV) market has been booming to meet the global energy demand and to reduce the carbon emissions from energy production. Among all the PV

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · When discussing solar panel meaning, monocrystalline silicon solar panels refer to photovoltaic panels made from a single-crystal silicon structure.

Progress in n-type monocrystalline silicon for high

May 21, 2024 · ABsTrACT Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Degradation analysis of photovoltaic modules with solar cells

May 1, 2025 · This paper presents an evaluation of monocrystalline silicon photovoltaic (PV) modules after 8.3 years of operation at an electric vehicle station in southern Brazil. Silicon

Environmental impact of monocrystalline silicon photovoltaic

May 9, 2025 · Solar photovoltaics is crucial in the low carbon transformation of the global energy industry, while the mainstream types of photovoltaic modules have changed considerably. The

Environmental impact of monocrystalline silicon photovoltaic modules

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Their study revealed that in both types of monocrystalline silicon PV modules, the production of monocrystalline silicon cells contributed the most to global warming potential,

Progress in n-type monocrystalline silicon for high

May 21, 2024 · Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are

Environmental impact of monocrystalline silicon photovoltaic

May 9, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Silicon for photovoltaic applications

Oct 15, 2006 · Silicon is used in photovoltaics (PV) as the starting material for monocrystalline and multicrystalline wafers as well as for thin film silicon modules. More than 90% of the annual

Environmental impact assessment of monocrystalline silicon

Jan 20, 2016 · Life cycle assessment on monocrystalline silicon (mono-Si) solar photovoltaic (PV) cell production in China is performed in the present study, aiming to evaluate the

Environmental impact of monocrystalline silicon photovoltaic modules

Download Citation | On Jun 1, 2025, Xuerou Sheng and others published Environmental impact of monocrystalline silicon photovoltaic modules | Find, read and cite all the research you need on

Mono-crystalline silicon photovoltaic cells under different

Dec 1, 2020 · First, mathematical modeling of the Mono-crystalline PV module in case of various irradiation levels is presented. A performance assessment of a PV module by considering the

Optimization of monocrystalline silicon photovoltaic module

Jun 11, 2025 · This study presents a systematic approach to enhance the efficiency of monocrystalline silicon photovoltaic module assembly lines using advanced simulation

Comparison of Monocrystalline and Polycrystalline Solar Modules

Jun 14, 2020 · As the typical representative of clean energy, solar energy generating systems has the characteristics of long development history, low manufacturing cost and high efficiency,

Explanation of the principle of monocrystalline silicon

Photovoltaic (PV) installations have experienced significant growth in the past 20 years. During this period, the solar industry has witnessed technological advances, cost reductions, and

High-efficiency Monocrystalline Silicon Solar Cells:

In this paper, the typical high-efficiency c-Si solar cells with conversion efficiencies of 25% or above are firstly summarized. The corresponding device structure, key technology and

What is the difference between monocrystalline and polycrystalline PV

Monocrystalline silicon photovoltaic modules use high-purity monocrystalline silicon materials, which have higher light conversion efficiency, typically ranging from 15% to 22%, generating

Comparative Analysis of the Performance of

Feb 17, 2022 · B. Photovoltaic (PV) A solar cell or also called Photovoltaic (PV) is a semiconductor chip that can convert solar energy directly into direct current electrical energy

6 FAQs about [Magadan monocrystalline silicon photovoltaic modules]

Will high efficiency solar cells be based on n-type monocrystalline wafers?

Future high efficiency silicon solar cells are expected to be based on n-type monocrystalline wafers. Cell and module photovoltaic conversion efficiency increases are required to contribute to lower cost per watt peak and to reduce balance of systems cost.

When will n-type mono-Si become a dominant material in the solar module market?

n-type mono-crystalline material to reach ~10% of the total Si solar module market by the year 2015, and over 30% by 2023 . This roadmap predicts a substantial shift from p-type to n-type mono-Si within the mono-Si material market . Past barriers to adoption of

What is a bifacial solar module?

LONGi launched its mono-PERC modules in 2016, featuring integrated PERC technology on monocrystalline silicon and low light degradation, and its cell efficiency has increased from 21% to 24.06%. Bifacial modules collect solar energy from both the front and back side of the module, increasing the total power output per module.

What is the difference between polycrystalline and monocrystalline solar panels?

At present, the polycrystalline and monocrystalline modules are mainly used in the rooftop or ground photovoltaic systems, the monocrystalline module has the good power generation yield and save the cost of land or rooftop with the same installed capacity.

How much power does a monocrystalline solar panel lose?

For the average solar radiation above 1000 W/m2 with an average ambient temperature of 33o C, the surface temperature of monocrystalline solar cells is around 30.6o C, a power loss of 2.3% occurs. Whereas in polycrystalline panels, when the surface temperature is 47.5o C, there is a power loss of about 10.12%.

Does partial shading affect the efficiency of photovoltaic modules?

In this research, partial shading influences on the efficiency of photovoltaic modules are explored. First, mathematical modeling of the Mono-crystalline PV module in case of various irradiation levels is presented. A performance assessment of a PV module by considering the electrical influence of the partial shading are then presented.

Update Information

- Degradation rate of photovoltaic monocrystalline silicon modules

- Cambodia monocrystalline silicon solar photovoltaic panels

- Benin monocrystalline silicon photovoltaic panel 580w

- Monocrystalline silicon photovoltaic panel price per square meter

- Canadian Monocrystalline Silicon Photovoltaic Panel Charging Station

- Sri Lanka monocrystalline silicon photovoltaic panel manufacturer

- Semi-transparent monocrystalline silicon photovoltaic panel price

- Afghanistan monocrystalline silicon photovoltaic panel charging

- Benefits of 315w monocrystalline silicon photovoltaic panels

- Rooftop monocrystalline silicon photovoltaic panels

- Photovoltaic panel monocrystalline silicon power

- Norwegian monocrystalline silicon photovoltaic panel manufacturer

- Kathmandu polycrystalline silicon solar photovoltaic panels

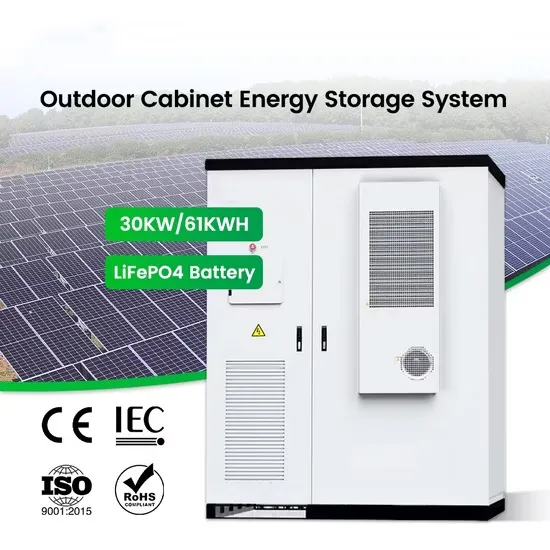

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.