Hotspot testing of glass/backsheet and glass/glass PV modules

Jan 1, 2023 · Continuous advances in the crystalline silicon photovoltaic (PV) module designs and economies of scale are driving down the cost of PV electricity and improving its reliability

The Hidden Downsides of Photovoltaic Glass Panels: What

But before you rush to replace your traditional windows, there''s a darker side to this shiny technology that''s often glossed over in marketing brochures. From unexpected costs to

What are the advantages of double-glass photovoltaic modules?

Oct 24, 2024 · 3. High conversion efficiency Double-glass photovoltaic modules use high-efficiency solar cells as photoelectric conversion devices, so they generate more electricity per

Photovoltaic glass panel disadvantages analysis chart

Photovoltaic glass panel disadvantages analysis chart What are the risks associated with PV panels? Recently,PV panel installations have also faced significant risks of degradation and

Are Glass-Glass PV Modules Right for Your Project? How to

Compared to single-glass PV modules, glass-glass PV modules deliver superior performance and longer service life. Learn more about their advantages, key purchasing considerations, and

Photovoltaic glass on it? What are its pros and cons?

May 10, 2024 · It is an important part of solar photovoltaic modules and has important values of protecting cells and light transmission. The advantages and disadvantages of photovoltaic

The advantages of glass glass solar panels with TOPCon cell

Dec 8, 2023 · With the evolution of solar energy as a dominant power source, industry leaders and experts are beginning to explore solutions beyond traditional solar panels. The technology

The Performance of Double Glass Photovoltaic Modules

Sep 1, 2017 · In recent years, with the rapid development of the photovoltaic industry, double glass module as a high reliability and high weather resistance produc

6 FAQs about [Disadvantages of glass photovoltaic modules]

Are glass-glass PV modules a problem?

Unfortunately, glass-glass PV modules are, similar to regular PV modules, subject to early life failures. A failure of growing concern are defects in the glass layer (s) of PV modules. The scale of decommissioned PV modules with glass defects will increase with the development of solar PV energy [ 7 ].

Are glass-glass PV modules more expensive than regular GBS modules?

While there are no technical disadvantages to glass-glass PV modules [ 10, 19 ], in general glass-glass PV designs are more expensive than regular GBS modules due to the use of an additional costly glass layer and the increased weight that may lead to higher costs for support structures.

How do glass defects affect a PV system?

Glass defects impact the economic performance of a PV system in multiple ways. The most obvious effect is the potential (in)direct performance loss of PV modules, which results in reduced economic revenues. Secondly, PV modules that suffer from glass defects may no longer meet safety requirements, therefore these modules are replaced.

How thick is a glass-glass PV module?

2.2. Glass characteristics Glass-glass PV modules generally use 2–3 mm thick glass layers, since thicker glass layers negatively impact the module's weight and costs, while trends are to reduce glass thickness to below 2 mm [ 10 ].

Why do PV modules need glass panels?

The replacement of the back sheet layer with a glass panel drastically reduces the proneness to water penetration. Ingress of water (vapor) at glass-glass PV modules is negligible and restricted to the edge area only [ 18 ].

Can PV modules survive a glass defect?

However, glass defects do not directly imply that PV modules endure internal damage nor that PV modules cannot continue to operate with minimal microcracks. Thus far, glass defects have been regarded as a failure beyond repair and no noticeable attempt has been made to develop reparation methods.

Update Information

- Russia St Petersburg double glass photovoltaic modules

- Photovoltaic glass photovoltaic modules

- Is double glass in photovoltaic modules conductive

- Middle East double glass photovoltaic modules

- How many millimeters does photovoltaic glass use

- Does photovoltaic glass have a front and back

- Which is the best photovoltaic glass customization company in Luanda

- Regulation of photovoltaic glass usage

- Photovoltaic glass factory design plan

- Glass photovoltaic roof sun room

- Glass curtain wall BIPV photovoltaic integration

- Athens Group Photovoltaic Tempered Glass

- Double-width polysilicon photovoltaic glass

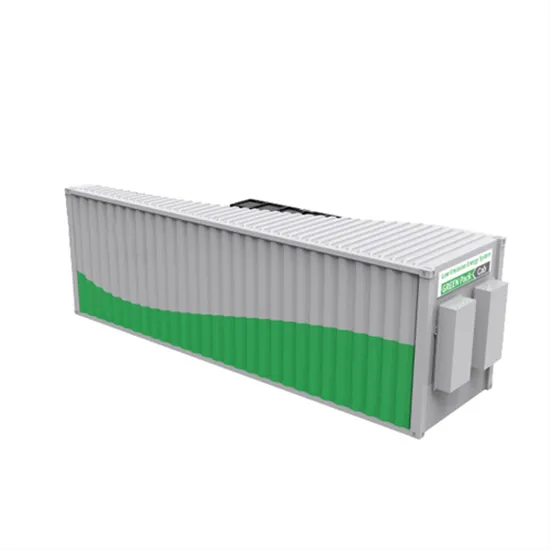

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.