Double-sided solar panels that follow the sun prove most

Jun 3, 2020 · Solar power systems with double-sided (bifacial) solar panels -- which collect sunlight from two sides instead of one -- and single-axis tracking technology that tilts the

Electrical performance of bifacial silicon PV modules under

Jan 1, 2019 · Agreement between single-side and double-side illumination approaches. Bifacial photovoltaic (PV) modules can increase the performance with respect to traditional PV

Which is heavier single-sided or double-sided

What is the difference between double-glass solar panels and single-sided solar panels? The main difference between double-glass photovoltaic modules and single-sided glass solar

Key Differences Between Double-sided and Single-sided

This article focuses on the advantages and disadvantages of double - sided and single - sided coated fluorinated backsheets for photovoltaic modules. Double - sided coated ones offer

Double-sided solar panel can provide the lowest

Jun 26, 2023 · Simply put, double-sided solar PV is a solar module that absorbs light from both sides of the panel. Traditional "single-sided" panels have a

RESULTS OF THE BIFACIAL PV CELLS AND PV MODULES

May 9, 2023 · Three different types of bifacial PV cells and three different types of bifacial PV modules are measured. The intercomparison involves measurements with systems using both

Differences between single-sided and double-sided

The model suggests that double-sided solar panels combined with single-axis tracking technology is most cost effective almost anywhere on the planet, although dual-axis trackers--which

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · According to the packaging technology of double-sided cells, it can be divided into double-sided double-glass modules and double-sided (with frame) modules. The structure of

Enhancement in efficiency of solar photovoltaic power

Jul 1, 2024 · Abstract Solar photovoltaic power generation is a productive and environmentally friendly technique. The results of objective evaluations show that double-sided power

The difference between single-sided and double-sided

Construction: Single-sided glass panels have a traditional design where the solar cells and other components are enclosed between a single layer of glass and a backing material. Durability:

Environmental impact assessment of the manufacture and

Sep 10, 2024 · Carbon emissions for both the P-type and N-type PV modules were lower only during the cell production phase but higher during the other stages when compared to the P

The Difference Between Double-glass and Single

Aug 17, 2023 · The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which

Which is heavier single-sided or double-sided

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design,which can impact their durability,performance,and

What is a double-sided double-glass photovoltaic module?

Jul 7, 2022 · Functional level: longer life cycle PERC double-glass double-sided modules integrate the anti-PID characteristics of double-glass modules, and have the advantages of high

The successful combination of double-sided solar cells and

Features of double-sided solar panels Conventional solar panels can only generate electricity from the front, while double-sided solar panels can not only generate electricity on both the

MATLAB modelling of double sided photovoltaic cell module

Keywords: double sided photovoltaic module • back irradiance • modelling • output characteristics • MPPT 1. Introduction Different from the traditional monofacial photovoltaic cells (mPV) with

A systematic literature review of the bifacial photovoltaic module

Aug 12, 2024 · Besides, the double-sided illumination method is quite expensive [59], and a single-sided illumination with a flash solar simulator at standard test conditions (STC) is

Photovoltaic panel single-sided specifications and

A photovoltaic (PV) module is an equipment that converts solar energy to electrical energy. A mathematical model should be presented to show the behavior of this device. The well-known

Horizontal single-axis tracking photovoltaic support for double-sided

The photovoltaic support can effectively increase the quantity of illumination of the back faces of the double-sided photovoltaic modules (1), and improve the photoelectric conversion efficiency

What is the difference between single-sided and double

Construction: Single-sided glass panels have a traditional design where the solar cells and other components are enclosed between a single layer of glass and a backing material. Durability:

Differences between single-sided and double-sided

Bifacial solar panels are a great type of solar panel that generates electricity by absorbing sunlight from both sides, increasing overall energy production. On the other hand, monocrystalline

What is the difference between single-sided and double

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design,which can impact their durability,performance,and

Differences between bifacial and single-sided photovoltaic modules

Monofacial solar panels utilize single-sided absorption to convert sunlight into electricity, while bifacial solar panels employ dual-sided absorption, capturing light from both the front and rear

6 FAQs about [Single-sided and double-sided photovoltaic modules]

What is a double sided solar cell?

The double-sided solar modules can be divided into P-type double-sided and N-type double-sided according to the different crystal silicon substrates. At present, the mass-produced double-sided solar cell structure is mainly composed of P-type PERC double-sided, N-PERT double-sided and HIT.

What is the difference between double-glass solar panels and single-sided solar panels?

The main difference between double-glass photovoltaic modules and single-sided glass solar panels lies in their construction and design, which can impact their durability, performance, and applications. Construction: Double-glass modules consist of two layers of glass sandwiching the solar cells and other components.

What is a single sided solar panel?

Construction: Single-sided glass panels have a traditional design where the solar cells and other components are enclosed between a single layer of glass and a backing material. Durability: While still durable, single-sided glass panels may be slightly more vulnerable to environmental factors compared to double-glass modules.

What is a double sided solar panel?

As the name suggests, it refers to a photovoltaic cell module formed by two pieces of glass and solar cells composed of a composite layer, and the cells are connected in series and connected in parallel to the lead ends. In recent years, double sided glass solar panels are like riding on a rocket, and their popularity is soaring.

How many double sided solar modules are there?

Among them, the total number of medium and double-sided solar modules in the application leader is about 2.6GW, accounting for 52%; the technical leader three bases 6 In the standard section, there are 4 sections to declare the double-sided technology.

What is a single glass solar panel?

Single glass solar panels typically feature a 3.2mm sheet for the front side and a backsheet made from a polymer material such as PVA. I didn’t make our choice of solar panels hinge on whether they were single or dual glass. But some of the claimed benefits of the latter include:

Update Information

- Photovoltaic modules double-glass double-sided

- Price of single-sided photovoltaic modules

- Prices of photovoltaic modules in Kinshasa

- Poor quality of exported photovoltaic modules

- Degradation rate of photovoltaic monocrystalline silicon modules

- Middle East double glass photovoltaic modules

- Photovoltaic modules on communication base station inverter

- Latest price of n-type photovoltaic modules

- Prices of p-type and n-type photovoltaic modules

- What are battery modules and photovoltaic modules

- Solar roof photovoltaic modules

- How much is the price of photovoltaic modules in Kigali

- Polish solar photovoltaic modules

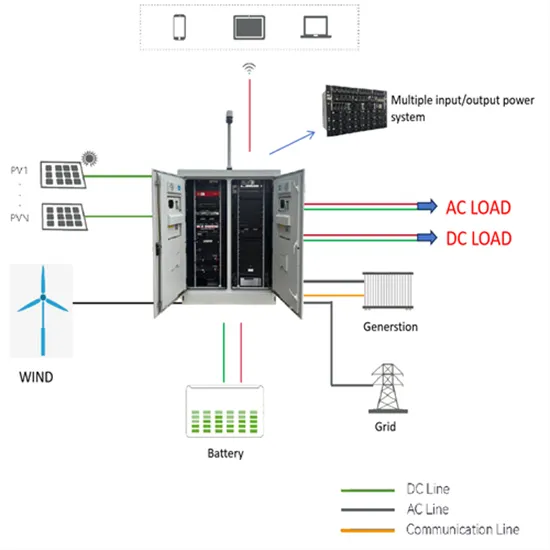

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

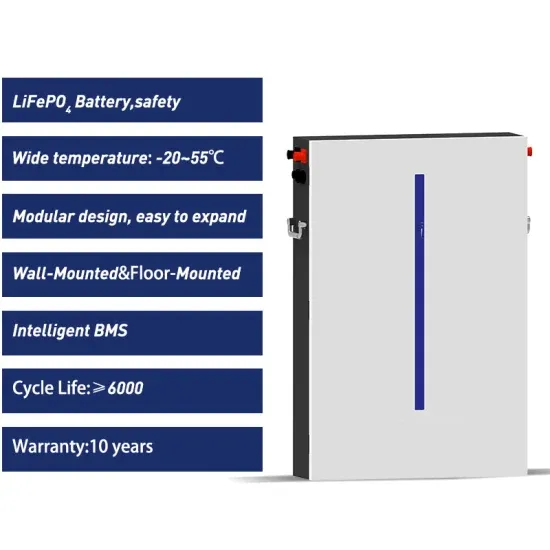

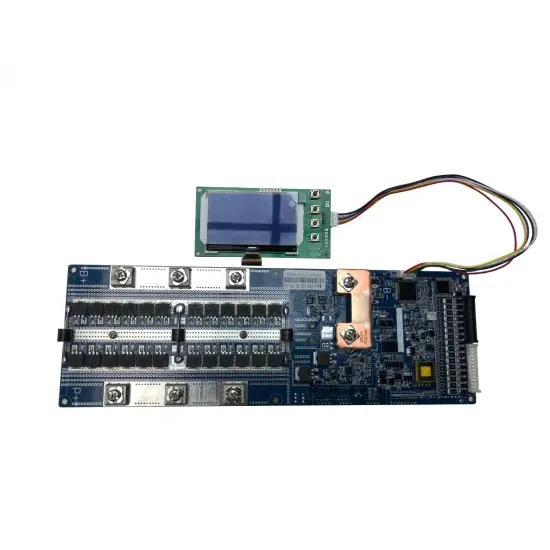

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.