High Purity Graphite Crucible Manufacturer

4 days ago · You can reuse it many times, thus effectively reducing the cost of use. In addition, you can also choose isostatic pressed high-purity graphite crucibles, molded high-purity

Graphite grades

Jul 1, 2024 · The sun, an energy available for free Photovoltaic systems use cells to convert sunlight directly into electricity. When sunlight strikes a PV cell, electrons are dislodged,

Co-recovery of Ag and Si from PV cell panels: Directional

Jan 19, 2025 · In the current context, a significant accumulation of photovoltaic (PV) waste poses a challenge without an efficient method for recovering high-value metal materials, such as

What are the industrial applications of graphite? Explore Its

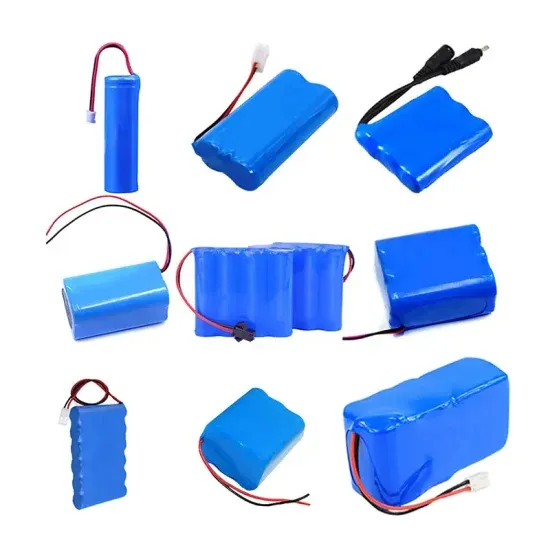

Lithium-Ion Batteries: Graphite is a key component in the anodes of lithium-ion batteries, which are widely used in portable electronics and electric vehicles. Photovoltaic Industry: It is used in

Graphite in renewable energy-solar

Feb 2, 2024 · Graphite''s high-temperature resistance, excellent electrical and thermal conductivity, and chemical stability are vital in the production of photovoltaic cells. Crystalline

CARBON AND GRAPHITE FOR PHOTOVOLTAIC INDUSTRY

Mar 23, 2012 · Carbone Lorraine is a world leader in isostatic graphite production, and proposes proven solutions to each step of the photovoltaic production chain, from polysili-con feedstock

Graphite Products: Revolutionizing the Glass Industry with

This blog explores the properties, production processes, applications, and recent advancements in graphite products for the glass industry, with a focus on their critical role in glass

Absorbed Glass Mat Battery

Jan 7, 2013 · AGM batteries, or Absorbed Glass Mat batteries, are sealed valve-regulated lead-acid batteries that utilize glass mats to hold the electrolyte, allowing for recombination of gases

Purification of Waste Graphite from Crucibles Used in

In this study, the waste graphite from crucibles used for photovoltaic crystal pulling was first purified by an alkali-acid method, and the experimental parameters were opti-mized to develop

Comparison of highly conductive natural and synthetic graphites

Jun 30, 2021 · The highest efficiency was achieved with a scaly graphite type electrode that yielded remarkably low sheet resistance of 4 Ohm/sq. and a PCE of 14.63% with a FF of

A review on electro-mechanical properties of solar photovoltaic

Jan 1, 2022 · The solar panels works based on photovoltaic effect. The photovoltaic effect is a process that generates voltage or electric current in a photovoltaic cell when solar energy

Experimental study of photovoltaic-thermoelectric systems

Jan 15, 2025 · Additionally, the use of pyrolytic graphite sheets led to a significant reduction in photovoltaic glass temperature, which was 28 % lower than the thermal grease arrangement

CARBON AND GRAPHITE FOR PHOTOVOLTAIC INDUSTRY

Mar 23, 2012 · The sun, an energy available for free Photovoltaic systems use cells to convert sunlight directly into electricity. When sunlight strikes a PV cell, electrons are dislodged,

What types of graphite products are used in the

Jun 20, 2023 · Graphite is a versatile material that finds its use in various industries, including the glass manufacturing industry. In this article, we will

Graphite Solutions for Photovoltaic Industry – Unlocking

Graphite is an excellent conductor of electricity, which makes it ideal for use in the electrical contacts of solar cells. Electrical conductivity is vital to efficiently transmit the electrical energy

Graphite for Photovoltaic Applications | High-Precision Graphite

Jul 18, 2025 · Graphite is the go-to material for high-performance photovoltaic components, from crucibles to jigs. With unmatched thermal conductivity and purity, it ensures consistent, reliable

Upcycling of photovoltaic waste graphite into high performance graphite

May 1, 2025 · Ultra-high temperatures (>3000 K) were provided by flash joule heat to remove harmful impurities in the PV waste graphite, while improving the graphitization degree of WG

6 FAQs about [Is graphite used in photovoltaic glass ]

Why is graphite important for the production of solar cells?

For the production of multicrystalline and monocrystalline silicon, the most important raw material in the production of solar cells in the photovoltaic industry, we are developing essential components based on specialty graphite for the highly sensitive process of crystal growth.

Can photovoltaic waste graphite be recycled?

High-value recycling of photovoltaic waste graphite (WG) is an effective path to achieve “carbon neutrality”. However, the current most adopted methods are landfilling, incineration and leaching, which can lead to undesirable environmental contamination and waste of resources.

Can photovoltaic waste graphite be recycled by flash Joule heating?

Conclusion In conclusion, the upcycling of photovoltaic waste graphite into high performance graphite anode realizes by flash Joule heating effectively. After rapid heating, the impurity content was reduced from 3.91 % to 1.45 %. The ID/IG value was reduced from 0.53 to 0.14, which effectively improved its graphitization degree.

Can photovoltaic WG be converted to graphite anode for lithium-ion batteries?

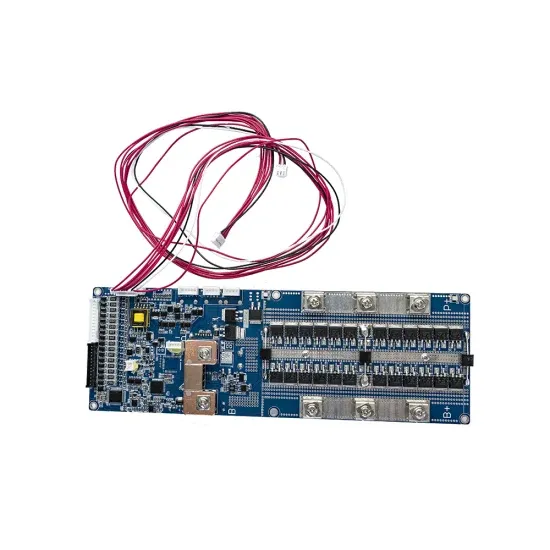

Here, an energy-efficient and high-value flash recycling strategy is developed in which photovoltaic WG is converted to high-capacity and high-rate graphite anode for lithium-ion batteries (LIBs) in milliseconds.

Does Flash Joule heat remove harmful impurities in PV waste graphite?

Ultra-high temperatures (>3000 K) were provided by flash joule heat to remove harmful impurities in the PV waste graphite, while improving the graphitization degree of WG and the (002) layer spacing of WG, making the upcycled graphite more suitable for lithium-ion (Li +) intercalation and deintercalation.

Why is graphite used in lithium ion batteries?

Graphite has been become the mainstream product of anode materials for LIBs owing to its advantages of low voltage platforms of in-deintercalation lithium, excellent conductivity and low price . It is estimated that 285 million tons of the battery-grade graphite will be required by 2035 .

Update Information

- Is tin used in the production of photovoltaic glass

- What kind of vehicle is used to transport photovoltaic glass

- Photovoltaic glass is used in houses

- Where is photovoltaic glass used

- Photovoltaic glass companies investigated

- Cuban photovoltaic glass company

- Photovoltaic glass 900x400

- FeSi and Photovoltaic Glass

- Photovoltaic Glass Greenhouse Ecological Park

- Photovoltaic glass selection

- Philippine Photovoltaic Glass Company

- Phosphorus silicon glass layer photovoltaic

- Botswana Photovoltaic Glass Sun Room

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.