Photovoltaic Cells and Systems | SpringerLink

Feb 15, 2023 · Silicon has four valence electrons. When silicon makes a bond with a group 15 element phosphorus (P), phosphorus donates one electron and forms the n-type layer. On the

Status and perspectives of crystalline silicon photovoltaics in

Mar 7, 2022 · Crystalline silicon solar cells are today''s main photovoltaic technology, enabling the production of electricity with minimal carbon emissions and at an unprecedented low cost. This

Characterization of Monocrystalline Silicon Solar Cells

Nov 18, 2021 · The n-type dopant source comprises of phosphorus compounds along with N2 and O2 gaseous environment is widely used in the thermal diffusion for commercial solar cell

Selective phosphorus doping of polycrystalline silicon on glass

Dec 15, 2021 · Abstract We report doping of thin (~60 nm) amorphous silicon (a-Si) on glass substrate to form n + polycrystalline silicon on glass in selective regions using Monolayer

Investigation of the P-doped lead-free glass frit based on the

Sep 15, 2021 · P-doped lead-free glass frit is prepared by the low-temperature phosphorus diffusion method, which solves the problem of low doping efficiency caused by phosphorus

(PDF) Ex-situ phosphorus-doped polycrystalline

Mar 31, 2023 · We present ex-situ phosphorus-doped polycrystalline silicon (poly-Si) passivating contacts fabricated by the physical vapour deposition method,

Understanding phosphorus diffusion into silicon in a

Sep 22, 2014 · Phosphorus (P) diffusion in crystalline silicon is a well-known phenomenon which has been thoroughly studied in the past 40 years [13]. However, the formation of the n++

Environmental impact assessment of the manufacture and

Sep 10, 2024 · Subsequently, we performed a life cycle assessment of Chinese silicon N-type- and P-type PV modules. The research system encompassed the production processes for

Characterization of Monocrystalline Silicon Solar Cells

Nov 18, 2021 · Crystalline silicon (c-Si) solar cells currently dominates roughly 90% of the PV market due to the high efficiency (η) of up to 25% [3]. The diffusion process is the heart of the

Optimizing phosphorus diffusion for photovoltaic

May 23, 2017 · The phosphosilicate glass (PSG), fabricated by tube furnace diffusion using a POCl3 source, is widely used as a dopant source in the manufacturing of crystalline silicon

A Well-Controlled PSG Layer on Silicon Solar Cells against

Jan 29, 2015 · This study proposes a promising silicon (Si) solar cell structure for reducing the potential induced degradation (PID) of crystalline Si solar cells. Phosphorous silicate glass

Solar Cells on Multicrystalline Silicon Thin Films Converted

Sep 2, 2024 · Fabrication and characterization of solar cells based on multicrystalline silicon (mc-Si) thin films are described and synthesized from low-cost soda-lime glass (SLG). The

Formation of Selective Emitter from Phosphorus Diffusion By

May 6, 2024 · We investigated laser parameters for a laser doping (LD) process that enables to improve cell characteristics through the formation of a selective emitter (SE) multicrystalline

Mechanisms involved in the formation of phosphosilicate glass

Apr 4, 2011 · This study focused on how the formation of phosphosilicate glass (PSG) film affects the solar cell emitter profile when using an inline ultrasonic mist phosphoric acid source and an

Revealing the effect of phosphorus diffusion gettering on

Apr 1, 2025 · Here we have conducted a comprehensive experimental and theoretical investigation into the impact of the phosphorus diffusion gettering (PDG) process on n-type

Influence of Pre-deposition Temperature of Phosphorous Silicate Glass

Jun 18, 2025 · Abstract In this work, we have studied the influence of pre-deposition temperature (from 600 to 800°C) of PSG (Phosphorous Silicate Glass) layers on the formation of n+/n

Suitability of POCl3 diffusion processes with in-situ

Sep 27, 2017 · Detailed characterizations of the grown layers on the silicon surface are performed after diffusion with respect to the individu-al layer thicknesses of the phosphosilicate glass

Understanding Crystalline Silicon PV Technology

Mar 6, 2023 · Understanding photovoltaic technology, and in particular, crystalline silicon PV technology is crucial for those seeking to adopt renewable energy

Optimizing phosphorus diffusion for photovoltaic

Sep 30, 2022 · The phosphosilicate glass (PSG), fabricated by tube furnace diffusion using a POCl3 source, is widely used as a dopant source in the manufacturing of crystalline silicon

What are Solar Cells and Solar Panels Made of?

Nov 24, 2024 · The n-type silicon is created by including atoms that have one more electron in their outer level than silicon, such as phosphorus. A solar cell consists of a layer of p-type

How Do Solar Cells Work? Photovoltaic Cells

Jul 25, 2024 · In this article, we''ll look at photovoltaic (PV) solar cells, or solar cells, which are electronic devices that generate electricity when exposed to

Photovoltaic and interface characteristics of mono-crystalline silicon

Jan 1, 2023 · Then, a phosphorus diffused n + -emitter with a sheet resistance of 130 ± 10 Ω square −1 and phosphorus-silicon-glass removal were achieved. After rear n + -emitter

Advances in the Understanding of Phosphorus

Sep 24, 2012 · This is because, although the diffusion of phosphorus is very slow in an oxide layer, the phosphorus atoms actually react with the silicon oxide

6 FAQs about [Phosphorus silicon glass layer photovoltaic]

What is phosphosilicate glass (PSG) layer system?

The phosphosilicate glass (PSG) layer system grown on the silicon surface during diffusion processes with phosphorus oxychloride (POCl 3) is a two-layer stack system consisting of a PSG and a silicon dioxide (SiO 2) layer. Understanding the stack layers’ structure and composition is essential for further optimizing POCl 3 diffusion processes.

How do phosphorus silicate glass layers affect PV efficiencies?

Phosphorous silicate glass (PSG) layers were carefully designed on an emitter layer to determine how they affect the efficiencies of solar cells before and after PID. A current-voltage (I-V) tester was used to determine PV parameters. An ellipseometer and transmission electron microscope (TEM) were used to measure the thicknesses of the PSG layers.

What is phosphosilicate glass?

In the diffusion process, a glass, known as phosphosilicate glass, of phosphorus pentaoxide (P 2 O 5 ) and silicon dioxide (SiO 2 ) are formed due to the uncontrolled amount of dopant and irregular diffusion at the silicon surface.

Why is phosphorus diffusion gettering used in silicon photovoltaic technology?

Metallic impurities are one of the main recombination losses in silicon substrates, leading to a decrease in the PCE of solar cells [, , ]. Phosphorus diffusion gettering (PDG) has been most widely used in silicon photovoltaic technology due to its high capture efficiency and metal mobility at high temperatures [, , , ].

Why is phosphorus oxychloride used in photovoltaics?

The diffusion of phosphorus mediated by phosphorus oxychloride (POCl_3) is extensively used in photovoltaics due to its enhanced diffusion speed and to the high controllability of the phosphorus at the wafer surface.

What are crystalline silicon solar cells?

Crystalline silicon (c-Si) solar cells currently dominates roughly 90% of the PV market due to the high efficiency (η) of up to 25% . The diffusion process is the heart of the silicon solar cell fabrication. The n-type emitter of most crystalline p-type silicon solar cells is formed by phosphorus diffusion .

Update Information

- Kuwait New Energy Photovoltaic Power Generation Glass Crystalline Silicon

- Crystalline silicon thin film glass photovoltaic innovation products

- Regulation of photovoltaic glass usage

- Sierra Leone single glass photovoltaic module price

- Advantages of photovoltaic glass panels

- The lowest thickness of photovoltaic glass

- Montevideo China Glass Photovoltaic Glass Branch

- Txw photovoltaic glass

- Photovoltaic transparent glass manufacturers

- Photovoltaic Glass Briefing

- Kyrgyzstan Photovoltaic Glass Panel Company

- How many millimeters does photovoltaic glass use

- Photovoltaic glass transportation damage

Solar Storage Container Market Growth

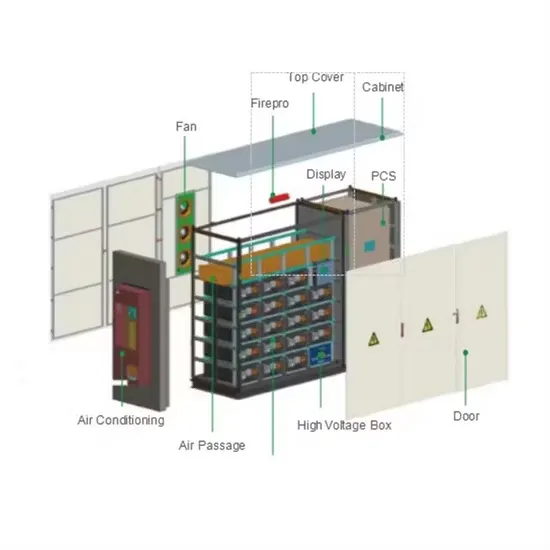

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.