The Application of ITO Glass in Photovoltaic Cells – Demo

Indium Tin Oxide (ITO) glass plays a crucial role in the field of photovoltaics, contributing to the enhancement of solar cell performance. This transparent conductive oxide is widely utilized as

Solar Glass: What Is It & What Is Its Role In Solar

Jul 22, 2021 · It should be pointed out that there are differences between the production lines of PV embossed glass and float glass. If the supply of PV

Photovoltaic Glass Tin Application Revolutionizing Solar

Photovoltaic glass tin application has emerged as a game-changer in the solar energy sector. By integrating tin-based coatings into glass surfaces, this technology enhances light absorption

What are thin-film solar cells? description, and types

Sep 26, 2019 · Where are thin-film solar cells used? It is used in constructing integrated photovoltaic power systems and as a semi-transparent photovoltaic glazing material that can

Critical sustainability issues in the production of wind and

Mar 10, 2022 · However, there are critical sustainability issues connected to the production of wind turbines, solar photovoltaic modules, electric vehicles and lithium-ion batteries such as

The use of recycled semiconductor material in crystalline silicon

Feb 1, 2020 · The analysis of the photovoltaic cell life cycle scenario including material recycling presented in this article was performed using SimaPro software and data combined and

Solar Glass & Mirrors, Photovoltaics | Solar Energy

Solar Glass & Mirrors Glass is used in photovoltaic modules as layer of protection against the elements. In thin-film technology, glass also serves as the substrate upon which the

Behaviour of oxygen in the tin bath used in float glass

May 19, 2017 · In addition, float glass is produced for various solar applications such as substrate and cover glass for photovoltaic cells, cover glass for thermal collectors and mirrors for solar

A novel recycling approach: separation and analysis of TCO-coated glass

Apr 3, 2025 · The ubiquitous adoption of photovoltaic (PV) modules as a renewable energy source for electricity generation has led to significant increase in their deployment. Among thin

How photovoltaic glass is made

Apr 23, 2024 · Once the glass mix is sufficiently liquid, it is poured onto a bed of molten tin and allowed to float on top of the tin, creating a smooth, flat sheet of glass of uniform thickness.

PHOTOVOLTAIC GLAZING IN BUILDINGS

Jul 15, 2022 · PV glazing is an innovative technology which apart from electricity production can reduce energy consumption in terms of cooling, heating and artificial lighting. It uses

Enhancing photovoltaic performance in tin-based perovskite

May 30, 2025 · Abstract The quest for solar energy focuses on photovoltaics, with perovskites emerging as efficient materials due to their high energy conversion and low production costs.

Solar Photovoltaic Glass: Features, Type and

Jun 27, 2023 · Photovoltaic glass is a special type of glass that utilizes solar radiation to generate electricity by laminating into solar cells, and has relevant

Photovoltaic Glass Waste Recycling in the Development of Glass

Apr 3, 2023 · Fluorine-doped tin oxide (FTO) was deposited as back contact on the glass substrates by spray pyrolysis. The chemical composition of the glass materials was evaluated

Addressing uncertain antimony content in solar glass for

Nov 7, 2023 · Glass accounts for a significant propor on of PV module weight, making glass recycling an environmentally beneficial process due to reduced CO2 emissions and energy

Glass for photovoltaics – a promising material for the

May 21, 2024 · ABSTRACT Glass plays an increasingly important role in photovoltaics. The rising demand for solar modules is pushing the glass industry to the fore. As a result, mechanical

Insight on tin use in glass production

Oct 17, 2017 · Tin is used in the production of float glass in a liquid "tin bath" to provide a flat surface over which molten glass can float and solidify. Hou Yinglan estimates that there were

Insight on tin use in glass production

Oct 17, 2017 · Hou''s presentation also outlined the use of tin in chemical glass coatings, although this amounted to just 300 tonnes of annual refined tin use inside China. ITRI View: Float glass

Recycling of photovoltaic modules for recovery and

Apr 1, 2023 · Recycling of PV comprises repairing, direct reuse, and recycling of materials chemically and mechanically from different types of decommissioned photovoltaic modules.

Photovoltaic Glass Waste Recycling in the Development of

Apr 3, 2023 · Because of the increasing demand for photovoltaic energy and the generation of end-of-life photovoltaic waste forecast, the feasibility to produce glass substrates for

6 FAQs about [Is tin used in the production of photovoltaic glass ]

Why is tin important for solar power?

As solar technology advances, securing a stable supply of key metals, particularly tin and copper, is crucial for maintaining the efficiency, performance, and longevity of solar power systems. Tin – Used in solders to create strong, conductive joints between solar cells, ensuring reliable electrical connections.

How much tin will the solar industry use in 2022?

ITA estimates the solar industry will use over 22,000 tonnes of tin in 2022, passing the 20,000 tonne threshold. The new estimates come after PV Tech released their PV Manufacturing & Technology Quarterly report, expecting global solar module production in 2022 to

How is tin oxide deposited on glass substrates?

Fluorine-doped tin oxide (FTO) was deposited as back contact on the glass substrates by spray pyrolysis. The chemical composition of the glass materials was evaluated by X-ray fluorescence (XRF), the thermal stability was measured by differential thermal analysis (DTA) and the transmittance was determined by UV-VIS spectroscopy.

How much tin is used in float glass production?

Tin use in float glass production totalled some 3,900 tonnes in China and 7,100 tonnes worldwide in 2016, according to estimates by Hou Yinglan from the Zhangzhou Kibing Glass company, who presented at ITRI’s Asia Tin Week in Kunming.

What is tin & how does it work?

Tin is a crucial part of solar power infrastructure. Solar panels are formed of many individual solar cells, connected by “solar ribbon”. This ribbon is a copper wire, coated in a thin layer of tin solder. The ribbon carries the charge to the edge of the panel, where it feeds into junction boxes.

Can tin be used as a heat energy storage medium?

Tin is also being explored as a heat energy storage medium on solar farms that concentrate sunlight using mirrors. Thermal technologies such as solar water heaters are likely to become more important.

Update Information

- Where is photovoltaic glass used

- Photovoltaic glass production company in Valparaiso Chile

- What kind of vehicle is used to transport photovoltaic glass

- Second photovoltaic glass production in Podgorica

- Production of photovoltaic glass panels

- Photovoltaic glass is used in houses

- Can ordinary glass photovoltaic panels be used

- Nicosia 2025 Photovoltaic Glass

- Photovoltaic glass frame loss

- Photovoltaic glass separation and sorting equipment

- Canberra Photovoltaic Glass Factory

- Philippine Photovoltaic Glass Company

- What is the proportion of photovoltaic glass cells

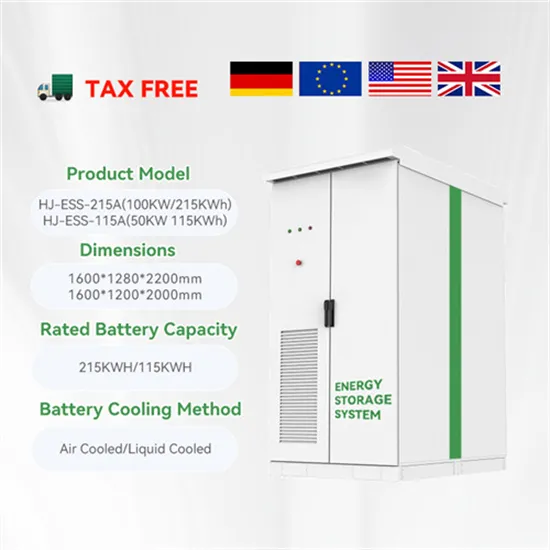

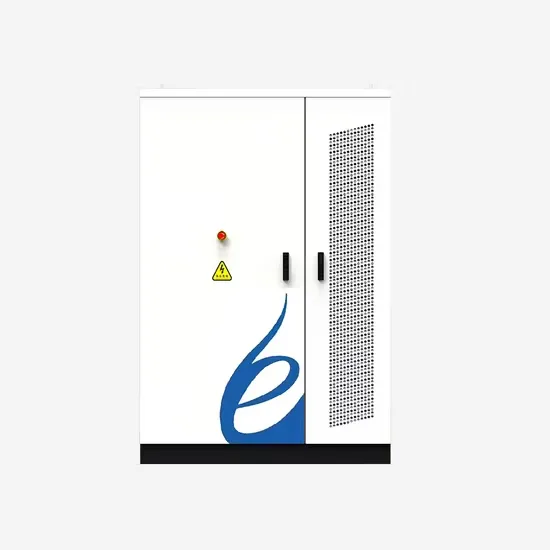

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.