Single crystal photovoltaic panel and polycrystalline

Monocrystalline (mono) panels use a single silicon crystal, while polycrystalline (poly) panels use multiple crystals melted together. Here''s a breakdown of how each type of cell is made. Mono

Monocrystalline silicon photovoltaic panel specifications

We''''re professional 400 watt monocrystalline solar panel manufacturers and suppliers in China, specialized in providing high quality products made in China for sale. it uses monocrystalline

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Pupin, P.C., et al.: Monocrystalline silicon solar cell for producing monocrystalline photovoltaic panels: a case study of Brazil. Energy Sources Part a-Recovery Utilization and

Experimental, economic and life cycle assessments of

Mar 15, 2022 · As seen in the figure, peaks at 37, 44, 64 and 77° correspond to the crystalline peaks of monocrystalline silicon (JCPDS No. 01-089-905), indicating and verifying that the

Monocrystalline Silicon Solar Panels: Efficient

Feb 3, 2025 · Monocrystalline silicon solar panels have an efficiency range of 18% to 22%, making them one of the most efficient photovoltaic panels available.

Environmental impact of monocrystalline silicon photovoltaic

Jun 30, 2025 · The most promising N-type TOPCon monocrystalline silicon photovoltaic module is examined through the life cycle environmental impact assessment, and focus is placed on

Why Monocrystalline Silicon PV Panels Are the Best Choice

Sep 29, 2024 · Monocrystalline silicon PV panels, commonly known as single-crystal panels, are generally considered the best option for solar energy systems due to their superior efficiency,

Monocrystalline Solar Panel — Everything You

Feb 27, 2021 · A monocrystalline PV panel is a premium energy-producing panel consisting of smaller monocrystalline solar cells (60 to 72 cells). Their superior

Monocrystalline silicon photovoltaic panel specifications

Unlike monocrystalline and polycrystalline solar panels, thin-film solar panels are manufactured using photovoltaic substances which include Amorphous silicon (a-Si), copper

Monocrystalline Silicon Cell

Monocrystalline silicon cells are defined as photovoltaic cells produced from single silicon crystals using the Czochralski method, characterized by their high efficiency of 16 to 24%, dark colors,

Monocrystalline vs Polycrystalline Solar Cells and How to

Mar 12, 2025 · Monocrystalline and polycrystalline silicon solar panels With the rapid development of solar photovoltaic energy storage, its solar panel technology update iteration is also very

Monocrystalline Solar Panels Explained

Aug 13, 2025 · Monocrystalline solar panels explained Are monocrystalline solar panels a good investment for UK homeowners? With 44% of the solar PV market share, monocrystalline

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · One type of solar panel that has gained significant attention is the monocrystalline solar panel. Monocrystalline solar panels are known for their

Crystallization processes for photovoltaic silicon ingots:

Sep 1, 2024 · Challenges in monocrystalline and multicrystalline silicon ingot production are discussed. The choice of the crystallization process plays a crucial role in determining the

Monocrystalline Solar Panels: How They Work,

Sep 16, 2023 · Monocrystalline solar panels utilize monocrystalline silicon cells to transform sunlight into usable electrical energy. These cells are made from

Monocrystalline silicon solar panels

The main difference between monocrystalline and polycrystalline solar cells in Hindi is the type of silicon solar cell they use; monocrystalline solar panels have solar cells made from a single

Monocrystalline silicon: efficiency and manufacturing process

Feb 6, 2025 · Monocrystalline solar panels are the most efficient type, with conversion rates often exceeding 22%. These panels are made from a single-crystal silicon structure, which

Assessment of toxicity tests for photovoltaic panels: A review

Jun 1, 2024 · Regarding the composition of PV panels, the typical structure of a monocrystalline silicon solar panel, shown in Figure 2, is basically composed of an aluminum frame, glass,

Solar Photovoltaic Diamond Wire Market Size, Growth

The monocrystalline silicon application segment represents the fastest-growing area within the solar photovoltaic diamond wire market, driven by the increasing preference for high-efficiency

Types of photovoltaic solar panels and their

Nov 6, 2017 · Instead of using silicon in crystalline form, they use a thin layer of photovoltaic material deposited on a substrate such as glass, plastic or metal.

6 FAQs about [Monocrystalline silicon photovoltaic panel sample]

Why is monocrystalline silicon used in solar panels?

Monocrystalline silicon is used to manufacture high-performance photovoltaic panels. The quality requirements for monocrystalline solar panels are not very demanding. In this type of boards the demands on structural imperfections are less high compared to microelectronics applications. For this reason, lower quality silicon is used.

What is a monocrystalline solar panel?

The monocrystalline panel represents one of the most advanced technologies in the field of solar panels. Its main characteristic lies in the use of a single silicon crystal, hence the term monocrystalline. This crystal is extracted from a larger block of silicon through a sophisticated process that ensures a high degree of purity.

How are monocrystalline solar panels made?

The manufacturing process of monocrystalline solar panels is intricate and involves several steps. It begins with the Czochralski process, where a seed crystal is dipped into molten silicon. As the seed crystal is slowly pulled up, it forms a cylindrical ingot of single-crystal silicon.

What are the advantages of monocrystalline solar panels?

Monocrystalline solar panels offer a series of advantages. Thanks to their high degree of silicon purity, they are considered the most efficient. The efficiency rate, which measures the amount of solar energy converted into electrical energy, usually ranges between 12% and 19%.

How much power does a monocrystalline photovoltaic panel produce?

Monocrystalline photovoltaic panels have an average power ranging from 300 to 400 Wp (peak power), but there are also models that reach 500 Wp. The purity of silicon in these monocrystalline panels guarantees reliable energy production even in conditions of reduced sunlight.

How do you identify monocrystalline panels?

They are easily recognizable by their uniform and dark color. Monocrystalline panels are composed of monocrystalline cells obtained by cutting slices of silicon ingots through the Czochralski system.

Update Information

- 10w monocrystalline silicon photovoltaic panel

- Photovoltaic panel monocrystalline silicon power

- Afghanistan monocrystalline silicon photovoltaic panel charging

- Photovoltaic panel monocrystalline silicon wafer

- Monocrystalline silicon photovoltaic panel price per square meter

- Benin monocrystalline silicon photovoltaic panel 580w

- Sri Lanka monocrystalline silicon photovoltaic panel manufacturer

- Monocrystalline photovoltaic panel standards

- Harare monocrystalline photovoltaic panel manufacturer

- Which photovoltaic panel is better single crystal silicon n-type or p-type

- Monocrystalline photovoltaic panel components

- Monocrystalline silicon photovoltaic module specifications

- Rooftop monocrystalline silicon photovoltaic panels

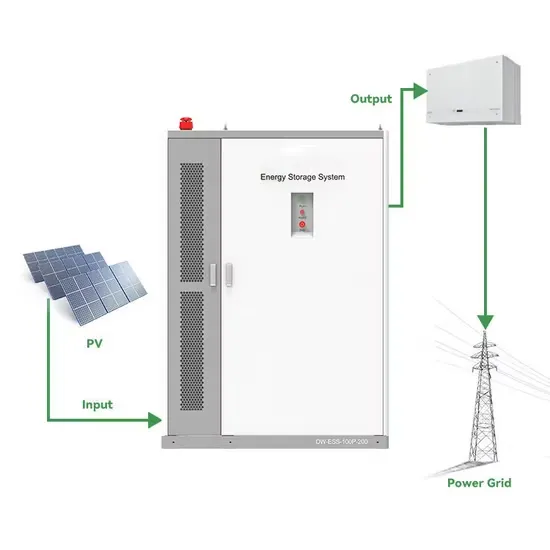

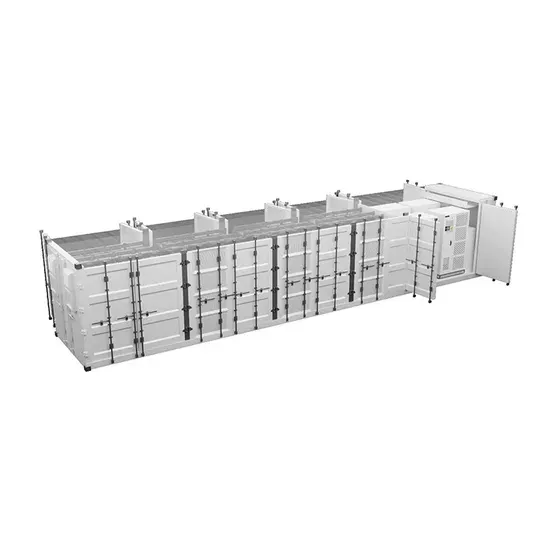

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.