Fabricating Different Types of Photovoltaic Cells

Jun 2, 2021 · A silicon wafer made from a single silicon crystal grown in the shape of a cylindrical ingot is defined as a monocrystalline wafer (see figure 1). In a

The solar energy industry has witnessed remarkable

Mar 1, 2025 · What Are Solar Wafers? A solar wafer, also known as a silicon wafer, is a thin slice of crystalline silicon that serves as the foundation for fabricating integrated circuits in

How thick is the solar monocrystalline silicon

Aug 10, 2024 · The exploration of monocrystalline silicon wafer thickness holds profound implications for the solar energy sector, encompassing aspects such

Evolution of Silicon Wafer Size

Jan 14, 2022 · Over the years, the silicon wafer size has experienced a process from small to large. The increase in silicon wafer size and the continuous progress of photovoltaic

Solar Silicon Wafer Market | Global Market Analysis Report

Aug 11, 2025 · Solar Silicon Wafer Market Solar Silicon Wafer Market Size and Share Forecast Outlook 2025 to 2035 The solar silicon wafer market is projected to grow from USD 16.8 billion

Researchers build 20-μm-thin monocrystalline

Oct 4, 2023 · The epitaxial thin silicon layer is then lifted off from the porous silicon substrate. Via this process, the scientists obtained a p-type 20μm -thick

Photovoltaic (PV) Cell Types | Monocrystalline,

5 days ago · The article provides an overview of the main types of photovoltaic (PV) cells, including monocrystalline, polycrystalline, and thin-film solar

Solar Wafers: Key to Efficient Solar Panels

Nov 3, 2023 · Defining Photovoltaic Wafers a.k.a Solar Cells Photovoltaic wafers or cells, also known as solar cell wafers, use the photovoltaic effect to convert

What Makes Monocrystalline PV Panels So Efficient

Sep 29, 2024 · Monocrystalline silicon photovoltaic panels are highly efficient due to their complete crystal structure, with a photoelectric conversion rate of 22% to 27%. They are highly

Monocrystalline Silicon Wafer Recovery Via Chemical Etching

Mar 20, 2024 · Globally, end-of-life photovoltaic (PV) waste is turning into a serious environmental problem. The most possible solution to this issue is to develop technology that allows the

How thick is the solar monocrystalline silicon

Aug 10, 2024 · Monocrystalline silicon wafers serve as fundamental elements in solar photovoltaic cells. They are predominantly manufactured from high-purity

The difference between monocrystalline silicon

May 24, 2024 · The magical silicon wafer that converts solar energy into electrical energy is the core of photovoltaic technology. Today, let''s take a closer look at

Enhancing surface properties of monocrystalline silicon

Apr 1, 2025 · Abstract Monocrystalline silicon (mono-Si) solar cells are widely recognized for their high conversion efficiency and reliability, making them the dominant technology in the

A method to recycle silicon wafer from end-of-life photovoltaic

Apr 1, 2017 · This paper details an innovative recycling process to recover silicon (Si) wafer from solar panels. Using these recycled wafers, we fabricated Pb-free

Stiffness and fracture analysis of photovoltaic grade silicon plates

Oct 15, 2016 · In the photovoltaic (PV) domain most of the literature deals with the improvement of the electrical efficiency, by acting on some physico-chemical parameters. However, it is also

A method to recycle silicon wafer from end-of-life photovoltaic

Apr 1, 2017 · A method to recycle silicon wafer from end-of-life photovoltaic module and solar panels by using recycled silicon wafers Jeongeun Shin a, Jongsung Park b, Nochang Park a

Life Cycle Assessment of Monocrystalline Silicon Solar Cells

Feb 28, 2025 · Pupin, P.C., et al.: Monocrystalline silicon solar cell for producing monocrystalline photovoltaic panels: a case study of Brazil. Energy Sources Part a-Recovery Utilization and

Explanation of the principle of monocrystalline silicon

A conventional crystalline silicon solar cell (as of 2005). Electrical contacts made from busbars (the larger silver-colored strips) and fingers (the smaller ones) are printed on the silicon wafer.

The solar cell wafering process

May 21, 2024 · Groove on the surface of a monocrystalline silicon wafer featuring a micro-crack developed under the groove due to the indentation of a silicon carbide particle during multi

Review of silicon recovery in the photovoltaic industry

Dec 1, 2023 · Figure 1 illustrates the value chain of the silicon photovoltaic industry, ranging from industrial silicon through polysilicon, monocrystalline silicon, silicon wafer cutting, solar cell

A wafer-based monocrystalline silicon photovoltaics road

Jul 1, 2013 · As an initial investigation into the current and potential economics of one of today''s most widely deployed photovoltaic technologies, we have engaged in a detailed analysis of

6 FAQs about [Photovoltaic panel monocrystalline silicon wafer]

What are silicon wafer-based photovoltaic cells?

Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology. EcoFlow’s rigid, flexible, and portable solar panels use the highest quality monocrystalline silicon solar cells, offering industry-leading efficiency for residential on-grid and off-grid applications.

Are monocrystalline silicon wafers a good choice for solar panels?

Monocrystalline silicon wafers show excellent performance, with efficiencies reaching up to 22%. There is a continuous effort to reach the highest efficiency possible for solar cells, aiming close to 32%. The balance of efficiency, energy production, and affordability is key for sustainable solar panel production.

What is a solar wafer?

Solar wafers are crucial for this clean energy option. They are made of monocrystalline or polycrystalline silicon. This makes up 95% of today’s solar panel market. Monocrystalline silicon is top-notch, with efficiencies between 18% and 22%. This is remarkable since the highest efficiency for silicon solar cells is around 32%.

Which solar panels use wafer based solar cells?

Both polycrystalline and monocrystalline solar panels use wafer-based silicon solar cells. The only alternatives to wafer-based solar cells that are commercially available are low-efficiency thin-film cells. Silicon wafer-based solar cells produce far more electricity from available sunlight than thin-film solar cells.

Do thin-film solar cells use silicon wafers?

Thin-film solar cells don’t use silicon wafers but are highly inefficient and rarely used. Silicon wafer-based photovoltaic cells are the essential building blocks of modern solar technology.

What type of silicon do solar panels use?

Solar panels mainly use monocrystalline or polycrystalline silicon for today’s photovoltaic technology. Monocrystalline silicon wafers show excellent performance, with efficiencies reaching up to 22%. There is a continuous effort to reach the highest efficiency possible for solar cells, aiming close to 32%.

Update Information

- Norwegian monocrystalline silicon photovoltaic panel manufacturer

- Semi-transparent monocrystalline silicon photovoltaic panel price

- Monocrystalline silicon photovoltaic panel sample

- Canadian Monocrystalline Silicon Photovoltaic Panel Charging Station

- Monocrystalline silicon photovoltaic panel price per square meter

- Benin monocrystalline silicon photovoltaic panel 580w

- Sri Lanka monocrystalline silicon photovoltaic panel manufacturer

- Dominica crystalline silicon photovoltaic panel manufacturer

- Photovoltaic power generation silicon wafer integrated board

- 325w monocrystalline photovoltaic panel

- Degradation rate of photovoltaic monocrystalline silicon modules

- India Mumbai Monocrystalline Photovoltaic Panel BESS

- Rooftop monocrystalline silicon photovoltaic panels

Solar Storage Container Market Growth

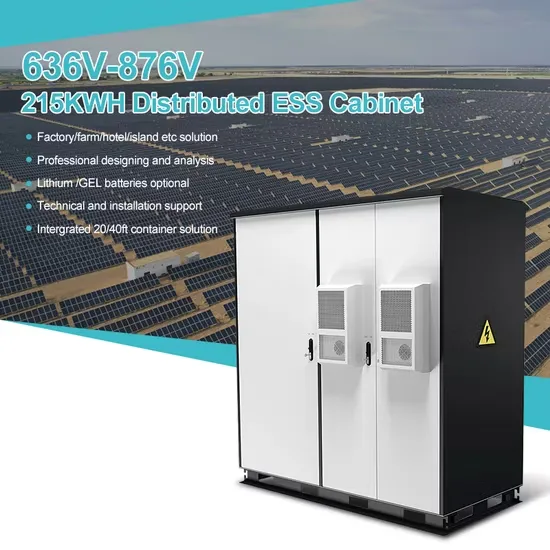

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.