Solar Panel Cost Per Square Meter: Breaking Down Prices

Jul 8, 2025 · For the high energy density use case, we use commercial-grade solar panels like TOPCon (used in HBOWA systems); in the case of residential use cases, monocrystalline

Monocrystalline Silicon and Photovoltaic Panel Prices: Key

As we approach Q2 2024, the solar industry''s facing a paradox: while monocrystalline silicon prices remain unstable, photovoltaic (PV) panel costs keep hitting record lows. What''s driving

Monocrystalline solar panels: a comprehensive guide

Aug 30, 2024 · How is a monocrystalline solar panel made Monocrystalline panels are thin slabs typically composed of 30-70 photovoltaic cells assembled, soldered together, and covered by

Exploring Monocrystalline Solar Panels: A Comprehensive

Nov 9, 2023 · 2. Can SolarClue® explain the manufacturing process of monocrystalline solar cells, detailing how single-crystal silicon ingots are produced, sliced into wafers, and

Cost per square meter of crystalline silicon photovoltaic

for 16% efficiency, the cost ranges from Rs 37 per Wp for above 300 W to Rs 68 per Wp for 50-100 W; while for panels with 17% efficiency, the cost ranges from Rs 36 per Wp

Monocrystalline silicon solar panels per square meter

Polycrystalline vs. Monocrystalline Solar Panels: The Ultimate Recently, monocrystalline panels have been dominating the residential solar market, thanks to their superior efficiency.

Understanding Photovoltaic Panel Costs: Price Per Watt and Per Square Meter

Understanding Photovoltaic Panel Costs: Price Per Watt and Per Square Meter The Solar Equation: Breaking Down Costs Let''s cut through the confusion – photovoltaic panel pricing

Monocrystalline vs Polycrystalline Solar Panels:

Jan 20, 2023 · The pros and cons of monocrystalline and polycrystalline cells come down to their basic physical difference. The major differences between

What Is A Monocrystalline Solar Panel? | Definition, Cost,

Feb 11, 2025 · A monocrystalline solar panel is a type of photovoltaic (PV) panel constructed from a single, continuous silicon crystal. This distinguishes them from polycrystalline panels, which

The Pros and Cons of Monocrystalline Solar Panels

5 days ago · This process ensures that the silicon material used in the panels is of high purity and uniformity, which results in a higher power output per square

Understanding Monocrystalline Solar Panel Prices in China

Jan 27, 2025 · The price of monocrystalline solar panels in China varies based on factors such as wattage, technology, and manufacturer. For instance, Jingsun Power offers a range of panels

How much does a solar silicon panel cost per

Feb 13, 2024 · The cost of solar silicon panels per square meter is influenced by various factors, including 1. the type and quality of the solar panel, 2. market

Comprehensive Guide to Monocrystalline Solar

Aug 13, 2025 · Monocrystalline solar panels are photovoltaic cells composed of a single piece of silicon. These cells contain a junction box and electrical cables,

Cost of solar panels in the UK

What types of solar panels can I install at home? There are three types of solar panels on the market for domestic use, varying in cost, efficiency and aesthetics. The type most suitable for

A Guide to Monocrystalline Solar Panels

Oct 7, 2024 · Monocrystalline solar panels have the further advantage of tending to be less affected by high temperatures when compared with polycrystalline solar panels. While this

Monocrystalline Photovoltaic Panel Market

Monocrystalline panel prices fell below $0.20 per watt in 2023, an 82% reduction from 2010 levels, eliminating the historical cost gap with polycrystalline technology. This steep price erosion

Total production costs for mono PERC c-Si solar components

Jul 4, 2025 · Polysilicon prices include the processing of metallurgical-grade silicon. The following prices from June 2021-May 2022 were used in this analysis: glass, USD 590/Mt; aluminium,

How much does a solar photovoltaic panel cost per 1w?

Mar 26, 2024 · Monocrystalline panels are manufactured using single-crystal silicon, which provides higher efficiency and space savings but typically comes with a steeper price tag.

Monocrystalline vs. Polycrystalline vs. Thin-Film

Mar 7, 2025 · When it comes to Monocrystalline vs. Polycrystalline vs. Thin-Film Solar Panels, understanding their distinct characteristics and benefits is

How much does solar silicon wafer cost per

Feb 1, 2024 · In summation, the price of solar silicon wafers per square meter is contingent upon an intricate interplay of factors, highlighting the importance of

Understanding Photovoltaic Panel Costs: Price Per Watt and Per Square Meter

Let''s cut through the confusion – photovoltaic panel pricing isn''t as straightforward as checking grocery store tags. The magic number you''re after depends on whether you''re looking at

A Guide to Monocrystalline vs Polycrystalline

Jul 13, 2023 · On average, monocrystalline solar panels cost £350 per square metre (m²), or £703 to buy and install a 350-watt (W) panel. Polycrystalline

6 FAQs about [Monocrystalline silicon photovoltaic panel price per square meter]

How much does a monocrystalline solar panel cost?

On average, monocrystalline solar panels cost £350 per square metre (m²), or £703 to buy and install a 350-watt (W) panel. Polycrystalline panels, on the other hand, cost around £280 per m², or £562 for a 350 W panel. This is partly because producing single-crystal silicon – used in monocrystalline panels – is a long, complicated process.

Why are monocrystalline solar panels more expensive than polycrystalline?

The cost of monocrystalline silicon solar panels has always been higher than polycrystalline. That is because of the higher production cost of monocrystalline silicon. In fact, monocrystalline silicon itself is produced from polycrystalline silicon, so naturally, the former will always be more expensive than the latter.

What is the efficiency of monocrystalline & polycrystalline solar panels?

The typical efficiency values for monocrystalline panels are between 18 to 22%, while the values are between 15 to 18% for polycrystalline panels. The efficiency of monocrystalline and polycrystalline silicon solar panels from 2006 to 2019 [Data source: Fraunhofer Institute]

What are monocrystalline silicon solar panels?

Monocrystalline silicon sun-energy panels are more widely used in solar rooftop systems. These panels are commonly preferred for large-scale solar PV installations. Such solar panels are used in different sectors such as industrial, commercial, or residential.

Where can I find information about monocrystalline solar panels?

Linquip is one of the best sources in the industry for information about monocrystalline solar panels, related equipment, and their installation, use, and maintenance. We at Linquip are always available to help you with any questions or concerns that you may have regarding solar panels or if you need any assistance with them in the future.

How many solar cells are in a monocrystalline solar panel?

Usually, a monocrystalline panel will contain either 60 or 72 solar cells, depending on the size of the panel. Most residential installations use 60-cell monocrystalline silicon panels. When sunlight falls on the monocrystalline solar panel, the cells absorb the energy, and through a complicated process create an electric field.

Update Information

- Semi-transparent monocrystalline silicon photovoltaic panel price

- Benin monocrystalline silicon photovoltaic panel 580w

- 545wp monocrystalline silicon photovoltaic module price

- Solar photovoltaic panel monocrystalline silicon folding panel 400w

- Monocrystalline silicon wafers and photovoltaic panel lifespan

- 10w monocrystalline silicon photovoltaic panel

- Mongolia monocrystalline photovoltaic panel price

- Price of photovoltaic panels per square meter

- How much does a double-sided single crystal 550W solar photovoltaic panel cost per square meter

- Photovoltaic silicon glass panel

- Port Louis polycrystalline photovoltaic panel price

- How much does a photovoltaic curtain wall cost per square meter in Azerbaijan

- 48v photovoltaic panel price

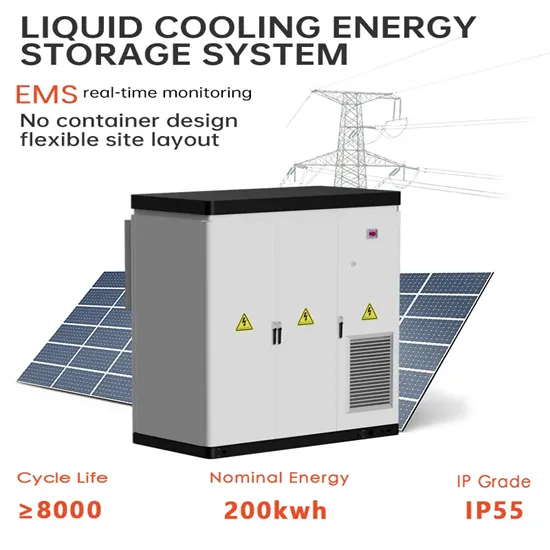

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.