Electrolyte tank costs are an overlooked factor in flow battery

Jan 3, 2025 · Electrolyte tank costs are often assumed insignificant in flow battery research. This work argues that these tanks can account for up to 40% of energy costs in large systems,

Researchers create smaller, cheaper flow batteries for

Jun 10, 2025 · existing flow battery technologies cost more than $200/kilowatt hour and are too expensive for practical application, but Liu''s lab in the School of Chemical and Biomolecular

cost estimation for CAES and flow batteries

Nov 7, 2023 · With current membranes and current densities, and some rough estimation of other costs, and extrapolation from current systems like vanadium flow batteries, cells for chelated

Electrolyte tank costs are an overlooked factor in flow battery

Jan 3, 2025 · Standardization of flow battery components and the development of high-voltage chemistries are highlighted as paths towards decreasing costs and achieving greater market

Flow Battery Price Breakdown: What You Need to Know in

Ever wondered why utilities are suddenly eyeing flow batteries like kids in a candy store? The flow battery price conversation has shifted from "if" to "when" as this technology becomes the dark

How does the cost of flow batteries compare to other

Dec 20, 2024 · Flow Batteries Cost Potential: Flow batteries have a potential levelized cost of storage (LCOS) that could be reduced to as low as $0.052/kWh by 2030, down from the

How do the operating costs of flow batteries compare to

Feb 3, 2025 · Flow Batteries: These have a maintenance cost 50% higher than lithium-ion batteries, with costs around $300 per maintenance cycle. Lithium-ion Batteries: Maintenance

An Introduction To Flow Batteries – Power

Oct 3, 2023 · Lithium-ion batteries get all the headlines, but flow batteries are a viable option, particularly for large-scale grid storage. Lithium-ion batteries

Lithium Redox Flow Batteries for High Power and High

Redox flow batteries (RFBs) are particularly appealing for many of these grid storage applications due to their independent scaling of power and energy, long operational lifetimes, and simplified

Passive components limit the cost reduction of

Nov 1, 2018 · To identify costs which are susceptible by the flow battery industry, we study the technology''s value chain by breaking down the costs. The main components of a flow battery

Flow Battery Price Breakdown: What You Need to Know in

Why Flow Battery Costs Are Making Headlines Ever wondered why utilities are suddenly eyeing flow batteries like kids in a candy store? The flow battery price conversation has shifted from

How do flow batteries compare to metal-air batteries in

Jan 13, 2025 · In conclusion, flow batteries offer better efficiency and proven scalability at somewhat higher cost complexity, while metal-air batteries, particularly iron-air, promise lower

Passive components limit the cost reduction of

Nov 1, 2018 · To date however, flow batteries struggle to compete with lithium-based batteries regarding system costs. To identify costs which are susceptible by the flow battery industry,

Utilities Are Trying Enormous ''Flow'' Batteries Big Enough to

Dec 1, 2024 · The other hurdle is their up-front cost. Vanadium flow batteries are at least twice as expensive to build as lithium-ion batteries, Rodby said, and banks are hesitant to lend money

Redox flow batteries: A step toward the mass market

Redox flow batteries are perfect for storing large quantities of renewable energy, but they have always been too expensive for the mass market. Researchers at the Fraunhofer Institute for

Why Isn''t This Revolutionary Battery Everywhere?

Mar 11, 2025 · Vanadium redox flow batteries are hitting the bigtime, and I mean big. One of the biggest Battery Energy Storage Systems (BESSs) ever is a vanadium redox flow battery that

Performance and cost characteristics of multi-electron transfer

Sep 30, 2016 · Non-aqueous redox flow batteries (NAqRFBs) have recently received considerable attention as promising high energy density, low cost grid-level energy storage technologies.

6 FAQs about [Flow batteries are too expensive]

Are flow batteries worth it?

While this might appear steep at first, over time, flow batteries can deliver value due to their longevity and scalability. Operational expenditures (OPEX), on the other hand, are ongoing costs associated with the use of the battery. This includes maintenance, replacement parts, and energy costs for operation.

Are flow batteries paying off?

That work seems to be paying off. In an August 2024 report “Achieving the Promise of Low-Cost Long Duration Energy Storage,” the U.S. Department of Energy (DOE) found flow batteries to have the lowest levelized cost of storage (LCOS) of any technology that isn’t geologically constrained.

Are flow batteries a low-cost long-term energy storage technology?

In an August 2024 report “Achieving the Promise of Low-Cost Long Duration Energy Storage,” the U.S. Department of Energy (DOE) found flow batteries to have the lowest levelized cost of storage (LCOS) of any technology that isn’t geologically constrained. DOE estimates that flow batteries can come to an LCOS of $0.055/kWh.

How can flow battery research reduce costs?

Standardization of flow battery components and the development of high-voltage chemistries are highlighted as paths towards decreasing costs and achieving greater market penetration. Electrolyte tank costs are often assumed insignificant in flow battery research.

Are flow batteries better than lithium ion batteries?

As we can see, flow batteries frequently offer a lower cost per kWh than lithium-ion counterparts. This is largely due to their longevity and scalability. Despite having a lower round-trip efficiency, flow batteries can withstand up to 20,000 cycles with minimal degradation, extending their lifespan and reducing the cost per kWh.

Are flow batteries a cost-effective choice?

However, the key to unlocking the potential of flow batteries lies in understanding their unique cost structure and capitalizing on their distinctive strengths. It’s clear that the cost per kWh of flow batteries may seem high at first glance. Yet, their long lifespan and scalability make them a cost-effective choice in the long run.

Update Information

- Low Voltage Flow Batteries

- Disadvantages of lithium flow batteries

- Mass production of flow batteries

- How to calculate the power of liquid flow batteries for communication base stations

- Requirements for flow batteries for communication base stations

- Power Battery Iron and Chromium Flow Batteries

- Irish companies using flow batteries

- Are lithium batteries in photovoltaic energy storage cabinets expensive

- EU Flow Batteries

- Differences between vanadium liquid flow batteries on the market

- Heterogeneous Flow Batteries

- Testing standards for container energy storage batteries

- Which communication base station lithium-ion batteries have UPS

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

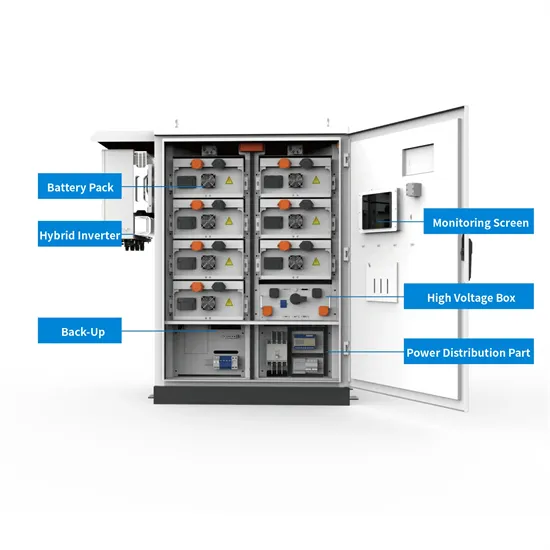

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.