Energy storage container waterproof test

What is a water spray test? TLS Energy International, a leader in the design and manufacture of BESS containers, integrates thorough testing procedures into their production process to

Full-scale walk-in containerized lithium-ion battery energy storage

Dec 1, 2022 · Three installation-level lithium-ion battery (LIB) energy storage system (ESS) tests were conducted to the specifications of the UL 9540A standard test method [1]. Each test

THE LATEST CERTIFICATION AND TESTING STANDARDS

We perform the evaluation, testing and certification, and standards solutions your battery and energy storage products require, leveraging our IECEE CB Scheme accreditation (which

Guide to Storage Safety Certifications | EVLO Energy

Mar 20, 2024 · NFPA 69 systems allow unaffected battery units to remain intact. This saves customers replacement costs should a thermal runaway event occur and allows rigorous

UL9540A: 2025 Interpretation of Thermal Runaway Fire Propagation Test

The UL9540A:2025 standard sets a new benchmark for battery energy storage safety, with system-level fire testing, advanced thermal data, and global certification impact.

Designing a BESS Container: A Comprehensive Guide to Battery Energy

Apr 10, 2023 · The Battery Energy Storage System (BESS) container design sequence is a series of steps that outline the design and development of a containerized energy storage system.

Global Overview of Energy Storage Performance Test

May 5, 2021 · Included in this standard are descriptions about capacity testing, a charge retention test, endurance in discharge-charge cycle, endurance in over charge, test for suitability for

Standards for Energy Storage Battery Containers: What You

Jan 7, 2023 · a massive battery container, quietly humming in a field, storing enough energy to power a small city. But here''s the kicker—without strict standards for energy storage battery

Battery Energy Storage储能电池及系统 System

Jun 12, 2023 · Energy储能系统(ESS) Storage System In recent years, the trend of combining electrochemical energy storage with new energy develops rapidly and it is common to move

Test procedure BMS temperature protection

Nov 7, 2017 · The purpose of this test procedure is to evaluate the harmful effects of a drop of (or bump against) the battery energy storage system container on the battery modules inside a

Explosion Control Guidance for Battery Energy Storage

4 days ago · EXECUTIVE SUMMARY Lithium-ion battery (LIB) energy storage systems (BESS) are integral to grid support, renewable energy integration, and backup power. However, they

THE LATEST CERTIFICATION AND TESTING STANDARDS

What is battery energy storage? Energy storage, primarily in the form of lithium-ion (Li-ion) battery systems, is growing by leaps and bounds. Analyst Wood Mackenzie forecasts nearly 12 GWh

Lithium-ion Battery Storage Technical Specifications

Apr 21, 2022 · The BESS components must comply with all codes and standards relevant to the operation and installation of energy storage equipment. All installed equipment must be tested

Overview of battery safety tests in standards for

This overview of currently available safety standards for batteries for stationary battery energy storage systems shows that a number of standards exist that include some of the safety tests

BATTERY ENERGY STORAGE SYSTEMS (BESS)

Apr 28, 2025 · Aside from presenting a viable opportunity for energy storage or balancing electrical grids, BESS present significant fire and explosion risks, due to employment of

Major Battery Energy Storage Systems Pass Large-Scale Fire Testing

Jun 20, 2025 · — This ongoing development in fire safety testing for battery energy storage systems demonstrates the industry''s commitment to enhancing safety standards and ensuring

Standards for Energy Storage Battery Containers: What You

Jan 7, 2023 · From California to Shanghai, regulators are scrambling to keep up with battery tech. Here''s what''s trending: 1. The Big Three: NFPA 855, IEC 62619, and China''s T/CES 173

Overview of battery safety tests in standards for

Feb 1, 2024 · This overview of currently available safety standards for batteries for stationary battery energy storage systems shows that a number of standards

6 FAQs about [Testing standards for container energy storage batteries]

Are there safety standards for batteries for stationary battery energy storage systems?

This overview of currently available safety standards for batteries for stationary battery energy storage systems shows that a number of standards exist that include some of the safety tests required by the Regulation concerning batteries and waste batteries, forming a good basis for the development of the regulatory tests.

What is a battery energy storage system container?

A Battery Energy Storage System container is more than a metal shell—it is a frontline safety barrier that shields high-value batteries, power-conversion gear and auxiliary electronics from mechanical shock, fire risk and harsh climates.

How to determine the safety of a battery?

The safety is estimated by several parameters of the battery’s first life and the current state of deterioration (e.g. measured by electrochemical impedance spectroscopy). During operation the battery’s SOC range shall be narrowed for energy and power intensive application by increasing the lower and reducing the upper voltage limit.

What is a battery safety test?

“This test shall evaluate the safety performance of a battery in internal short-circuit situations. The occurrence of internal short circuits, one of the main concerns for battery manufacturers, potentially leads to venting, thermal runaway, and sparking which can ignite the electrolyte vapours escaping from the cell.

What temperature should a battery be tested at?

“During this test, the battery shall be exposed to elevated temperatures (in IEC 62619 the temperature is 85°C) which can trigger exothermal decomposition reactions and lead to a thermal runaway in the cell.” The majority of the standards that include this test require to test at cell level.

What are the safety standards for secondary lithium batteries?

This standard outlines the product safety requirements and tests for secondary lithium (i.e. Li-ion) cells and batteries with a maximum DC voltage of 1500 V for the use in SBESS. This standards is about the safety of primary and secondary lithium batteries used as power sources.

Update Information

- Lithium battery energy storage container testing standards

- Energy storage container testing equipment manufacturer

- What are the standards for energy storage batteries

- The prospects of lithium-ion energy storage batteries

- 3 354mwh energy storage container 280 cells

- Antimony lead-acid batteries are the main energy storage

- Accra container energy storage device enterprise

- Huawei Tripoli Energy Storage Container

- Energy storage charging container manufacturer ranking

- Nano-ion batteries for energy storage power stations

- Recommended manufacturers of industrial and commercial energy storage batteries

- Which energy storage container liquid cooling manufacturers are there

- Which energy storage container is cheaper in Libreville

Solar Storage Container Market Growth

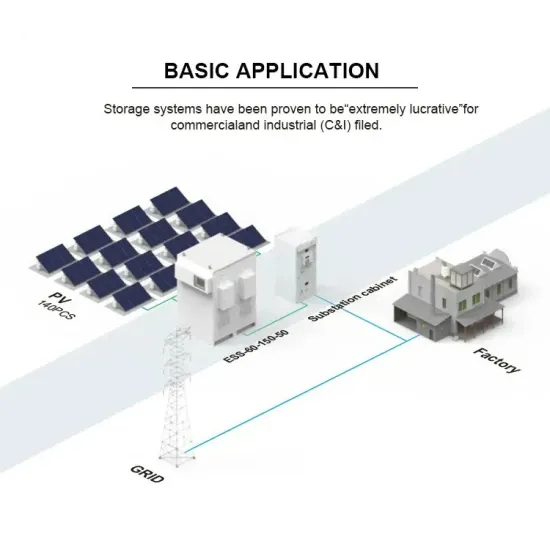

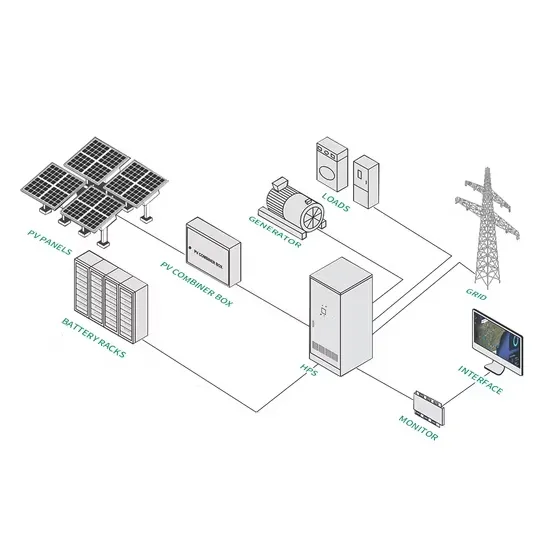

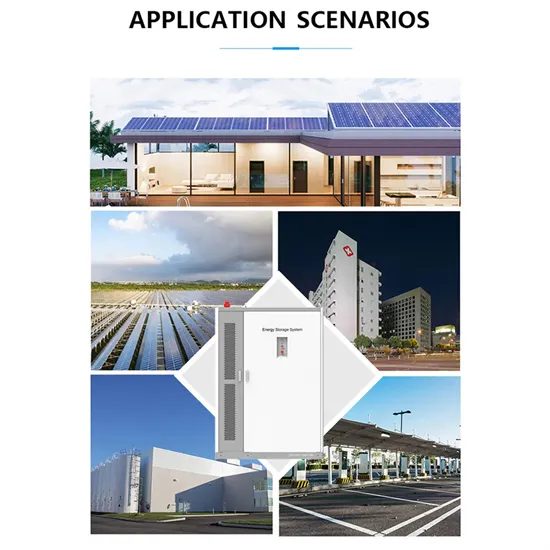

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

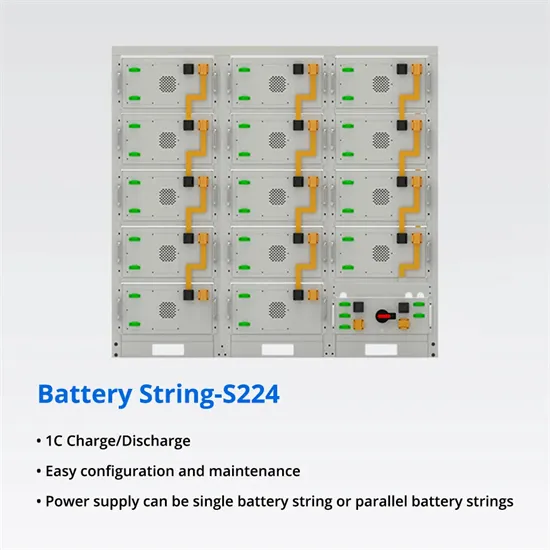

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.