Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · The redox flow battery is one of the most promising grid-scale energy storage technologies that has the potential to enable the widespread adoption of renewable energies

Advances in the design and fabrication of high-performance flow battery

May 26, 2021 · These novel electrode structures (dual-layer, dual-diameter, and hierarchical structure) open new avenues to develop ECF electrodes that can considerably improve the

Benchmarking organic active materials for aqueous redox flow batteries

Oct 21, 2023 · To guide research and implementation of aqueous organic redox flow batteries it is essential to estimate their potential costs. In this perspective, the authors present an overview

Carbon electrodes improving electrochemical activity and enhancing mass

Oct 1, 2020 · The aqueous flow battery that possesses the superior capacity balance between supply and demand is deemed as one of the most promising large-scale energy storage

The first mass production line of the world''s largest power

Jan 30, 2022 · The "Ronghe No. 1" iron chromium liquid flow battery stack mass production line with independent intellectual property rights of the state power investment was put into

Fundamental models for flow batteries

Aug 1, 2015 · The flow battery is a promising technology for large-scale storage of intermittent power generated from solar and wind farms owing to its unique advantages such as location

Progress and Perspectives of Flow Batteries: Material Design

Feb 28, 2025 · In this chapter, we summarize the state-of-art progress on the key components of FBs, including electrolytes (from classic inorganic to organic active materials), membranes,

New Flow Battery Chemistries for Long Duration Energy

Sep 27, 2024 · Abstract: Flow batteries, with their low environmental impact, inherent scalability and extended cycle life, are a key technology toward long duration energy storage, but their

Designing Better Flow Batteries: An Overview on

Jun 25, 2024 · Flow batteries (FBs) are very promising options for long duration energy storage (LDES) due to their attractive features of the decoupled energy

REDOX-FLOW BATTERY

May 16, 2024 · Redox-flow batteries are electrochemical energy storage devices based on a liquid storage medium. Energy conversion is carried out in electrochemical cells similar to fuel cells.

20 companies'' solid-state battery mass production "timetable"

Jul 16, 2024 · In recent years, with the vigorous development of the new energy vehicle market, solid-state batteries, as the core of the next generation of power battery technology, are

Flow battery startup scores $1.85 million federal

Feb 17, 2025 · Newcastle based clean-tech company Allegro Energy has secured $1.85 million in federal government funding to help bring its redox flow battery

Material design and engineering of next-generation flow-battery

Nov 8, 2016 · Flow-battery technologies open a new age of large-scale electrical energy-storage systems. This Review highlights the latest innovative materials and their technical feasibility for

Multiple Production Line Will be Put Into Production;

Sep 26, 2023 · In terms of policy, various global policies are poised to support the diversified advancement of sodium-ion batteries, flow batteries, and other technological pathways.

Flow Batteries: Safety, Cycle Life Advantages | Global Sources

Apr 2, 2024 · Electrolyte and cell stacks are the key components used in manufacturing flow batteries, respectively accounting for 40 and 30 percent of total production outlay. The cost of

Advanced lithium-ion battery process manufacturing

Jul 18, 2025 · Lithium-ion battery cell manufacturing depends on a few key raw materials and equipment manufacturers. Battery manufacturing faces global challenges and opportunities as

PRODUCTION OF LITHIUM-ION BATTERY CELL

Feb 7, 2024 · The Chair of Production Engineering of E-Mobility Components (PEM) of RWTH Aachen University has been researching lithium-ion battery production for many years. The

Effect of variable viscosity of electrolytes on mass transport

May 15, 2023 · A 2D model with the effect of variable viscosity is developed to elucidate the mass transport and electrochemical reaction processes in the flow battery. It is found that the

Emerging chemistries and molecular designs for flow batteries

Jun 17, 2022 · This Review summarizes the recent development of next-generation redox flow batteries, providing a critical overview of the emerging redox chemistries of active materials

From laboratory innovations to materials manufacturing for

Mar 30, 2023 · Here the authors review scientific challenges in realizing large-scale battery active materials manufacturing and cell processing, trying to address the important gap from battery

The first mass production line of the world''s largest power

Jan 30, 2022 · The "Ronghe No. 1" iron chromium liquid flow battery stack mass production line with independent intellectual property rights of the state power investment was put into operation.

Electrolyte engineering for efficient and stable vanadium redox flow

May 1, 2024 · The vanadium redox flow battery (VRFB), regarded as one of the most promising large-scale energy storage systems, exhibits substantial potential in th

Redox flow batteries for energy storage: their promise,

Aug 1, 2019 · Abstract Redox flow batteries continue to be developed for utility-scale energy storage applications. Progress on standardisation, safety and recycling regulations as well as

6 FAQs about [Mass production of flow batteries]

Why are flow batteries regarded as a promising large-scale energy storage technology?

7. Concluding remarks and perspectives Flow batteries are regarded as one of the most promising large-scale energy storage technologies because of their site-independency, decoupling of power and energy, design flexibility, long cycle life, and high safety.

How can a flow battery increase energy density?

To increase energy density, metal deposition chemistry, with low redox potentials and high capacity, can be adapted to combine with the flow battery (Fig. 1b); these technologies are called hybrid RFBs 12. For example, Li-metal-based flow batteries can achieve a voltage of over 3 V, which is beneficial for high-energy systems.

Are flow batteries a good option for long duration energy storage?

This article has not yet been cited by other publications. Flow batteries (FBs) are very promising options for long duration energy storage (LDES) due to their attractive features of the decoupled energy and power rating, scalability, and long lifetime.

Are flow batteries sustainable chemistries?

Abstract: Flow batteries, with their low environmental impact, inherent scalability and extended cycle life, are a key technology toward long duration energy storage, but their success hinges on new sustainable chemistries. This paper explores two chemistries, based on abundant and non-critical materials, namely all-iron and the zinc-iron.

Are redox flow batteries the future of energy storage?

Perspectives for high-performance electrodes are presented. The redox flow battery is one of the most promising grid-scale energy storage technologies that has the potential to enable the widespread adoption of renewable energies such as wind and solar.

Why do flow batteries have a large specific surface area?

It can be seen the specific surface area is inversely proportional to the fiber diameter, which means that a smaller fiber diameter is preferred to achieve a large specific surface area of the electrode. However, the electrodes for flow batteries need to be highly permeable for electrolyte transport.

Update Information

- Managua s first mass production of cylindrical lithium batteries

- Power Battery Iron and Chromium Flow Batteries

- Low Voltage Flow Batteries

- Have you bought any flow batteries

- Regulations on Liquid Flow Batteries for Public Small Base Station Equipment

- Differences between vanadium liquid flow batteries on the market

- Which companies have liquid flow batteries for communication base stations in Argentina

- What are the regulations for the location of flow batteries in communication base stations

- Lifespan of all-vanadium liquid flow batteries

- Manufacturers of iron-cadmium flow batteries

- What cables are used for flow batteries in communication base stations

- How many communication base station flow batteries are from Huawei

- Can flow batteries store

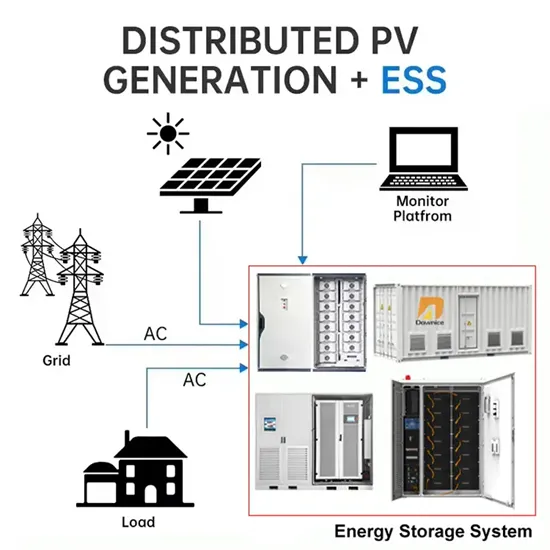

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.