Environmental feasibility of secondary use of electric vehicle

May 1, 2020 · The choice of allocation methods has significant influence on the results. Repurposing spent batteries in communication base stations (CBSs) is a promising option to

Optimization Control Strategy for Base Stations Based on Communication

Mar 31, 2024 · With the maturity and large-scale deployment of 5G technology, the proportion of energy consumption of base stations in the smart grid is increasing, and there is an urgent

Electrolyte solutions design for lithium-sulfur batteries

Sep 15, 2021 · Lithium-sulfur (Li-S) batteries, a promising next-generation energy storage system, has yet to realize the expected cycling life and energy density. The effect of electrolyte

Battery technology for communication base stations

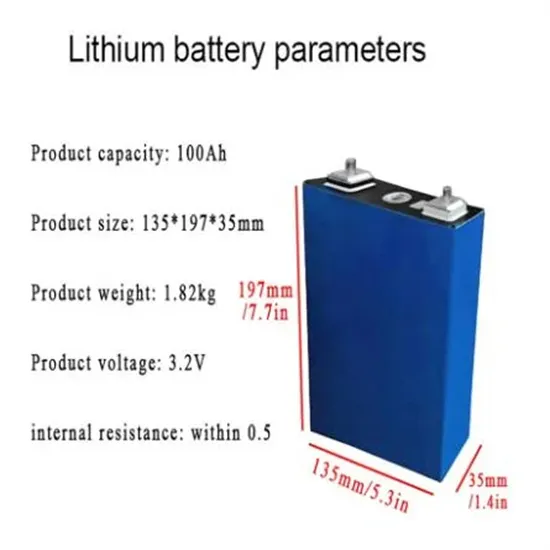

In order to ensure the reliability of communication, 5G base stations are usually equipped with lithium iron phosphate cascade batteries with high energy density and high charge and

Flow simulation and analysis of high-power flow batteries

Dec 20, 2015 · This paper seeks to build upon existing flow battery modeling literature by considering full cell designs with their associated flow delivery and removal passages, and by

Use of Batteries in the Telecommunications Industry

Mar 18, 2025 · Standby Power versus Energy Storage Systems Both Telecom dc plant and Data Center UPS are considered "Standby Power" Non cycling – 99% of time in "float condition"

Battery for Communication Base Stations Market

The global Battery for Communication Base Stations market size is projected to witness significant growth, with an estimated value of USD 10.5 billion in 2023 and a projected

What is the purpose of batteries at telecom base

Feb 10, 2025 · The lead storage battery is the most widely used energy storage battery in the current communication power supply. Among the many types of

Flow Battery Basics: Understanding The Technology

Dec 31, 2023 · What is a Flow Battery? A flow battery is a type of rechargeable battery that generates electrical energy by employing two chemical components dissolved in liquids, which

Redox Flow Batteries: Fundamentals and Applications

Sep 1, 2017 · Through storing energy in recirculating liquid electro-lytes, redox flow batteries have merits of decoupled energy density (tank size, electrolyte concentration, cell voltage and

【MANLY Battery】Lithium batteries for communication base stations

Mar 6, 2021 · In general, as the demand for 5G communication base stations continues to increase, there will be considerable market space for lithium battery energy storage in the

Energy consumption optimization of 5G base stations

Aug 1, 2023 · An energy consumption optimization strategy of 5G base stations (BSs) considering variable threshold sleep mechanism (ECOS-BS) is proposed, which includes the initial

Pathways to High-Power-Density Redox Flow

Jul 28, 2023 · Redox flow batteries (RFBs) promise to fill a crucial missing link in the energy transition: inexpensive and widely deployable grid and industrial

Collaborative Optimization of Base Station Backup Battery

Dec 18, 2023 · As the penetration rate of renewable energy in the power system grows, the need for the power system to find new flexible resources to maintain its stability in

Frontier tracking: Design of flow field for liquid flow batteries

Jun 19, 2025 · The article uses this model to verify the battery performance of all vanadium flow batteries, including voltage curve and battery voltage drop, and studies the battery

Coupled transport and electrochemical characteristics in redox flow

Aug 4, 2025 · The power output in a redox flow battery is greatly influenced by macro-to-micro mass transport and electrochemical reactions, which are coupled with each other and together

6 FAQs about [How to calculate the power of liquid flow batteries for communication base stations]

What is a flow battery?

Fig. 1. Power and energy densities of various EES systems. A flow battery is an electrochemical device that converts the chemical energy in the electro-active materials directly to electrical energy, similar to a conventional battery and fuel cells.

What determines the energy storage capacity of a flow battery?

Volume of electrolyte in external tanks determines energy storage capacity Flow batteries can be tailored for an particular application Very fast response times- < 1 msec Time to switch between full-power charge and full-power discharge Typically limited by controls and power electronics Potentially very long discharge times

What are the components of a flow battery?

Flow batteries comprise two components: Electrochemical cell Conversion between chemical and electrical energy External electrolyte storage tanks Energy storage Source: EPRI K. Webb ESE 471 5 Flow Battery Electrochemical Cell Electrochemical cell Two half-cellsseparated by a proton-exchange membrane(PEM)

Do flow batteries need a fluid model?

Flow batteries require electrolyte to be pumped through the cell stack Pumps require power Pump power affects efficiency Need a fluid model for the battery in order to understand how mechanical losses affect efficiency K. Webb ESE 471 29 RFB Fluid Model Power required to pump electrolyte through cell stack Pumping power is proportional to

What are the characteristics of a flow battery system?

Table I. Characteristics of Some Flow Battery Systems. the size of the engine and the energy density is determined by the size of the fuel tank. In a flow battery there is inherent safety of storing the active materials separately from the reactive point source.

How do redox flow batteries approach energy density?

The energy capacity requirement of a flow battery is addressed by the size of the external storage components. Consequently, a redox flow battery system could approach its theoretical energy density as the system is scaled up to a point where the weight or volume of the battery is small relative to that of the stored fuel and oxidant.

Update Information

- The scale of liquid flow batteries for communication base stations

- Which companies have liquid flow batteries for communication base stations in Argentina

- What cables are used for flow batteries in communication base stations

- How many communication base station flow batteries are from Huawei

- How to deal with small wind power in communication base stations

- Which manufacturers have flow batteries for Prague communication base stations

- What are the regulations for the location of flow batteries in communication base stations

- Requirements for flow batteries for communication base stations

- How to do distributed power generation at communication base stations

- How about uninterrupted power supply for communication base stations

- The crux of the difficulty in generating power through lithium-ion batteries for communication base stations

- Wind power measurement at communication base stations

- How many power signal base stations are there in Gitega

Solar Storage Container Market Growth

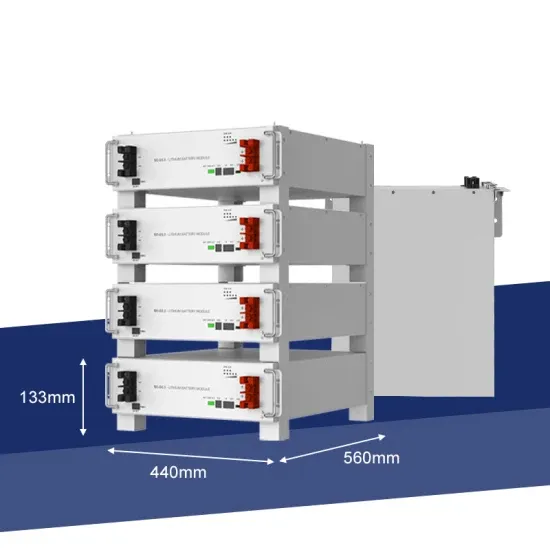

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.