Battery Design Module Application Library

Dec 13, 2022 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

圆柱形锂离子电池热建模

本模型示例模拟充放电循环期间以及随后舒张期的风冷圆柱 18650 锂离子电池。一维单电池模型用于对电池单元化学性质进行建模,二维轴对称模型用于对电池

Thermal Modeling of a Cylindrical Lithium-ion Battery in

Apr 15, 2015 · Introduction This example simulates an air-cooled cylindrical 18650 lithium-ion battery in 3D. The model follows the same approach as the Application Libraries example

Azerbaijan Battery Technology Market (2025-2031) | Trends

6W monitors the market across 60+ countries Globally, publishing an annual market outlook report that analyses trends, key drivers, Size, Volume, Revenue, opportunities, and market

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Could Cylindrical Batteries Become Standard for

Mar 25, 2024 · By the time the mainstream Tesla Model S hit the market in 2012, those 18650 cells were being made by Panasonic with as many as 7,728 cells

Analysis of Cylindrical Lithium Battery Advantages and Common Models

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

Baku lithium battery production company

BAK Power''''s products and services include cylindrical, prismatic and polymer batteries, battery packaging and battery solutions, which are mainly used in new energy vehicles, consumer

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Apr 28, 2025 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

Electrochemical and thermal modeling of lithium-ion batteries

May 1, 2024 · Yin et al. [173] investigated the aging of cylindrical lithium-ion batteries due to self-heating by developing an integrated battery model that couples a 3D electrochemical model

Types of Cylindrical Lithium-ion Cell

Apr 13, 2023 · Ⅰ. Introduction of cylindrical lithium-ion cell Cylindrical lithium batteries are divided into lithium cobalt oxide, lithium manganate, and ternary materials. The three data system

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Oct 28, 2021 · This example simulates an air-cooled cylindrical 18650 lithium-ion battery during a charge-discharge cycle, followed by a relaxing period. A lumped battery model is used to

A comprehensive review of battery modeling and state

Oct 1, 2020 · With the rapid development of new energy electric vehicles and smart grids, the demand for batteries is increasing. The battery management system (BMS) plays a crucial role

Azerbaijan: Cylindrical Lithium Batteries Market Report

The report provides a strategic analysis of the cylindrical lithium batteries market in Azerbaijan and describes the main market participants, growth and demand drivers, challenges, and all

A comprehensive numerical study on electrochemical-thermal models

May 1, 2022 · To evaluate the accuracy of cylindrical LIB models, eight electrochemical-thermal models (ECT) with different levels of fidelity and dimensionality (from one-dimensional (1D) to

A lumped-parameter electro-thermal model for cylindrical batteries

Jul 1, 2014 · Combining several existing lumped-parameter models, this paper presents an electro-thermal model for cylindrical batteries. The model consists of two sub-models, an

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Nov 29, 2021 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · This research proposes a novel experimental methodology and a theoretical model for evaluating the mechanical performance of cylindrical lithium-ion batteries under

Azerbaijan cylindrical lithium battery size

Cylindrical Primary Lithium Under rating current drain rates (~200mA), typical of many commercial devices, the "AA" size LiFeS2 battery has a specific energy density of ~297 Wh/kg compared

Azerbaijan Lithium-Ion Battery for Electric Vehicle Market

6Wresearch actively monitors the Azerbaijan Lithium-Ion Battery for Electric Vehicle Market and publishes its comprehensive annual report, highlighting emerging trends, growth drivers,

6 FAQs about [Azerbaijan cylindrical lithium battery model]

How to model a cylindrical lithium ion battery in 3D?

Thermal Modeling of a Cylindrical Lithium-Ion Battery in 3D This example simulates the heat profile in an air-cooled cylindrical battery in 3d. The battery is placed in a matrix in a battery pack. The thermal model is coupled to a 1d-battery model that is used to generate a heat source in the active battery material.

Why are lithium-ion batteries used in electric vehicles?

1. Introduction Cylindrical lithium-ion batteries (LIBs) have been widely used in electric vehicles (EVs) and hybrid electric vehicles (HEVs) due to their high energy density and longevity, lack of memory effect, and low self-discharge rate , , .

Are Ni-rich lithium ion batteries safe?

However, according to Noh et al., Ni-rich LIBs also have the disadvantage of poor thermal stability and capacity retention. Therefore, to ensure the safety and longevity of Ni-rich LIBs, the thermal and electrochemical states of batteries during charging and discharging must be carefully monitored and estimated.

How many ECT models are available for a Ni-rich 18650 type cylindrical Lib?

4. Conclusions In this study, eight different ECT models were established for a Ni-rich 18,650 type cylindrical LIB, with the most detailed Model 5 validated experimentally.

Are battery thermal behaviours based on cell-averaged heat generation rate?

However, 1D and 2D electrochemical models typically assume cell-averaged heat generation rate in calculating battery thermal behaviours, which are insufficient to capture the temperature and reaction rate non-uniformity.

What is the maximum non-uniformity of electrochemical reaction of a battery?

We can see that the Δ SOCmax reaches the maximum value when DOD = 70%, which also means that the maximum non-uniformity of electrochemical reaction of the battery is found at DOD = 70%. However, this non-uniformity will change with the change of the effective heat transfer coefficient.

Update Information

- Large cylindrical lithium battery model

- Huawei cylindrical lithium battery model

- Cylindrical lithium battery waterproof

- Cylindrical lithium battery assembly process

- Maximum temperature of cylindrical lithium battery

- BAK cylindrical lithium battery

- Praia lithium battery large cylindrical manufacturer

- Cylindrical lithium battery and square

- 60300 cylindrical lithium battery

- Lg large cylindrical lithium battery

- Togo custom made cylindrical lithium battery

- Belmopan Cylindrical Lithium Battery Factory

- Libya small cylindrical lithium iron phosphate battery

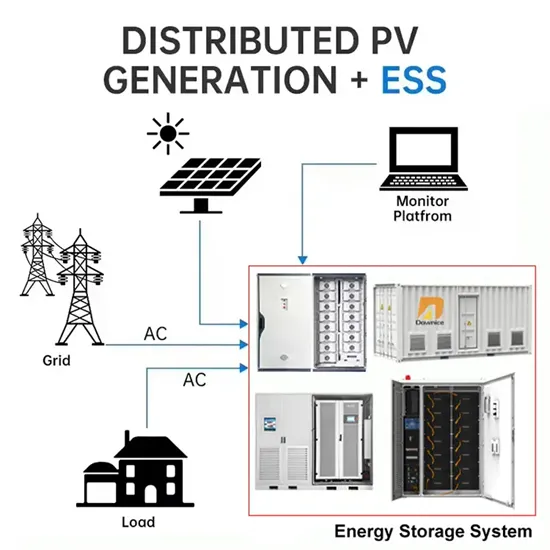

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.