Practical 4.7 V solid-state 18650 cylindrical lithium metal batteries

Jan 17, 2025 · Significantly, our LHCE-GPE allows for the operation of practical solid-state 18650 cylindrical LMBs at 4.7 V and industrial Li-ion batteries at 4.6 V, achieving high energy

What You Need to Know About Cylindrical Cells

May 20, 2025 · Cylindrical cells are robust lithium-ion batteries with high energy density, scalability, and durability, ideal for electric vehicles and energy storage systems.

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · This research proposes a novel experimental methodology and a theoretical model for evaluating the mechanical performance of cylindrical lithium-ion batteries under

An efficient physics-based thermal management model for cylindrical

Mar 1, 2025 · Abstract Conducting detailed thermal analysis of large-scale battery packs using physics-based electrochemical models is rare due to the computational burden. This study

Multi-Dimensional Electrochemical-Thermal Coupled

Sep 20, 2013 · Three dimensional features such as thermal/electrical paths design inside a cell, form factors, dimensions and local boundary conditions can have a significant impact on cell

Investigating thermal dynamics in cylindrical Li-ion batteries

4 days ago · Thermal dynamics in cylindrical Li-ion batteries, governed by electrochemical heat generation, are critical to performance and safety in high-power applications such as electric

A Computationally Efficient Coupled Electrochemical

Jan 1, 2019 · We present a one-dimensional, radial, coupled degradation-electrochemical-thermal (DET) model of a large format cylindrical lithium ion cell. The model consists of reduced order

Analysis of Cylindrical Lithium Battery Advantages and Common Models

According to data presented by Tesla, the 4680 large cylindrical lithium battery increases energy density by five times compared to the 21700 cylindrical cells, enhances mileage by 16%, and

Could Cylindrical Batteries Become Standard for

Mar 25, 2024 · By the time the mainstream Tesla Model S hit the market in 2012, those 18650 cells were being made by Panasonic with as many as 7,728 cells

Introduction of the Cylindrical Lithium Ion Battery

Apr 13, 2023 · Cylindrical lithium ion batteries are divided into different systems of lithium iron phosphate, lithium cobalt oxide, lithium manganate, cobalt-manganese hybrid, and ternary

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

A Computationally Efficient Coupled Electrochemical-Thermal Model

Sep 11, 2019 · We present a one-dimensional, radial, coupled degradation-electrochemical-thermal (DET) model of a large format cylindrical lithium ion cell. The model consists of

Potentials of 46 mm cylindrical cells: On the way

Apr 11, 2023 · Since Elon Musk announced the future use of a new battery cell format of type 4680 at the Tesla Battery Days two and a half years ago, a real

Thermal Modeling of Large Format Lithium-Ion Cells

Nov 30, 2012 · The rechargeable battery industry will experience significant growth in the near future given the increased need for battery systems for power electronics, renewable energy

Coupled electrochemical-thermal analysis of the novel

May 4, 2025 · The novel TESLA''s large format (LF) 4680 tabless cylindrical lithium-ion battery (LIB) represents a significant advancement in battery technology, promising higher energy

Analysis of Cylindrical Lithium Battery Advantages and Common Models

2. The Development History of Cylindrical Lithium Batteries Since Tesla''s Battery Day in September 2020 introduced the 4680 large cylindrical cells, these cells have once again

4680 large cylinder: the potential direction of high-end lithium

Apr 20, 2022 4680 large cylinder: the potential direction of high-end lithium batteries, the development of industrialization is accelerated The 4680 large cylindrical battery improves

Experimental and simulation study of direct current

Oct 10, 2023 · Understanding the contribution of internal direct current resistance (DCR) is crucial to the design and optimization of lithium-ion batteries (LIBs). However, the complex dynamic

A computationally efficient model for performance prediction of lithium

Feb 1, 2021 · The pseudo-two dimensional electrochemical model is capable of accurately predicting the transient behavior of the batteries. However, since the numerical complexity of

Multi-Dimensional Electrochemical-Thermal Coupled

Sep 20, 2013 · Multi-Dimensional Electrochemical-Thermal Coupled Model of Large Format Cylindrical Lithium Ion Cells 212th ECS Meeting Washington DC Oct 7-12, 2007

Large Cylindrical Battery Expand Ten Times More

May 22, 2025 · The fact that the volume change of large cylindrical battery far exceeds that of small cylindrical battery, with a difference exceeding tenfold.

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Oct 28, 2021 · A lumped battery model is used to model the battery cell chemistry, and a two-dimensional axisymmetrical model is used to model the temperature in the battery. The two

Three dimensional thermal-, electrical-, and

Nov 1, 2013 · Three dimensional thermal-, electrical-, and electrochemical-coupled model for cylindrical wound large format lithium-ion batteries Kyu-Jin Lee a b, Kandler Smith a, Ahmad

Comprehensive review of multi-scale Lithium-ion batteries

Feb 1, 2025 · This review integrates the state-of-the-art in lithium-ion battery modeling, covering various scales, from particle-level simulations to pack-level thermal management systems,

Size effect on the thermal and mechanical performance of cylindrical

Dec 1, 2024 · Abstract Increasing the size of cylindrical lithium-ion batteries (LIBs) to achieve higher energy densities and faster charging represents one effective tactics in nowadays

How to enable large format 4680 cylindrical lithium-ion batteries

Nov 1, 2023 · Large format 4680 cylindrical cells have become popular after Tesla filed a patent. If these cells are to become widely used, then understanding how to thermally manage them is

A systematic approach for electrochemical-thermal

Feb 23, 2018 · The 1D model of one electrode pair is combined with a 3D thermal model of a cell to capture the temperature distribution at the cell scale. Performance of the model is validated

6 FAQs about [Large cylindrical lithium battery model]

What is a large format lithium ion battery?

In recent years, large format lithium-ion batteries have been developed for applications such as electric vehicles [, , , , ]. Large format cells have a number of advantages over smaller form factors.

Which model is used to simulate a lithium-ion battery?

This example simulates an air-cooled cylindrical 18650 lithium-ion battery during a charge-discharge cycle, followed by a relaxing period. A lumped battery model is used to model the battery cell chemistry, and a two-dimensional axisymmetrical model is used to model the temperature in the battery.

What is a radial-electrochemical-thermal model of a lithium ion cell?

We present a one-dimensional, radial, coupled degradation-electrochemical-thermal (DET) model of a large format cylindrical lithium ion cell. The model consists of reduced order equations that describe the electrochemical phenomena, including that associated with degradation, coupled with an approximate model of thermal behavior.

Does cell design & cooling affect performance of cylindrical lithium-ion batteries?

Conclusions A distributed 3D coupled electro-thermal equivalent circuit network (ECN) model of cylindrical lithium-ion batteries is used to study the effect of cell design and cooling approach on performance. Multiple tab configurations and thermal management approaches are considered for 2170 and 4680 cells.

Why are large format lithium-ion batteries becoming more popular?

The demand for large format lithium-ion batteries is increasing, because they can be integrated and controlled easier at a system level. However, increasing the size leads to increased heat generation risking overheating. 1865 and 2170 cylindrical cells can be both base cooled or side cooled with reasonable efficiency.

What is a lumped battery model?

A lumped battery model is used to model the battery cell chemistry, and a two-dimensional axisymmetrical model is used to model the temperature in the battery. The two models are coupled by the generated heat source and the average temperature using the Electrochemical Heating multiphysics coupling node.

Update Information

- Andorra City cylindrical lithium battery model

- Huawei cylindrical lithium battery model

- Praia lithium battery large cylindrical manufacturer

- Azerbaijan cylindrical lithium battery model

- The smallest cylindrical rechargeable lithium battery

- Difference between Chilean lithium battery and cylindrical battery

- Power tool lithium battery 21v large capacity

- Marshall Islands cylindrical lithium battery 7260

- Paramaribo lithium battery cylindrical cell

- Asuncion cylindrical lithium battery custom manufacturer

- Large cylinder of lithium battery

- Rwanda cylindrical lithium battery use

- Mongolian cylindrical lithium battery is a battery

Solar Storage Container Market Growth

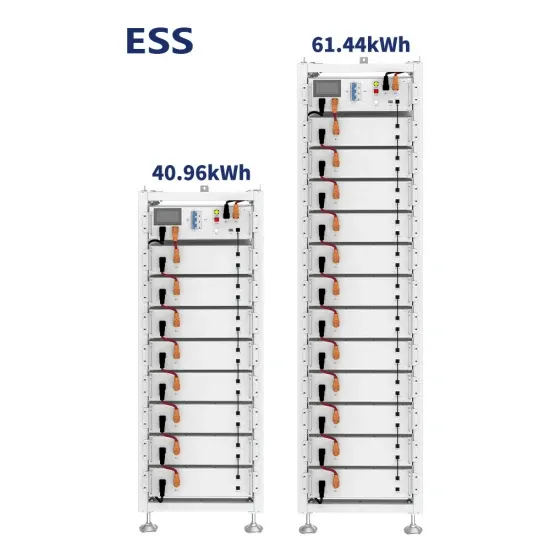

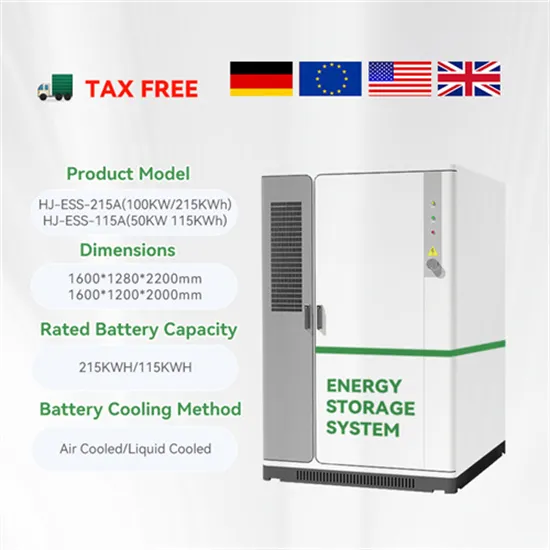

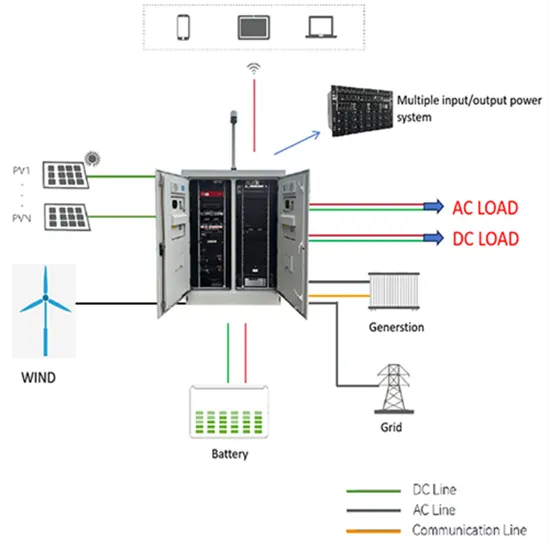

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.