Comprehensive review of multi-scale Lithium-ion batteries

Feb 1, 2025 · This review integrates the state-of-the-art in lithium-ion battery modeling, covering various scales, from particle-level simulations to pack-level thermal management systems,

Thermal Modeling of a Cylindrical Lithium-ion Battery in

Apr 15, 2015 · Introduction This example simulates an air-cooled cylindrical 18650 lithium-ion battery in 3D. The model follows the same approach as the Application Libraries example

Homogeneous constitutive relationship of cylindrical lithium

Jul 1, 2025 · This research proposes a novel experimental methodology and a theoretical model for evaluating the mechanical performance of cylindrical lithium-ion batteries under

Lithium for All | Huawei Digital Power

Huawei''s intelligent lithium battery solutions provide dynamic peak shifting, transforming traditional backup power systems into efficient energy storage solutions that enhance system flexibility

The clay-like mechanics model of cylindrical lithium-ion battery

A simple load case was chosen to reveal the essential mechanics properties of cylindrical lithium-ion battery and it was found that its mechanics characteristic is clay-like, according to the

An Electrochemical-Thermal Model for Lithium-Ion Battery

May 27, 2021 · Abstract In this study, an electrochemical–thermal coupled model is proposed to predict phenomena in battery packs that consist of lithium-ion battery cells during the driving of

Cylindrical Lithium Polymer Battery Mobile Phones For Iphone Huawei

Our Li Ion Mobile Phone Battery is designed for Iphone, Huawei, and AGV models. It comes with Size 18650, Capacity 2000mAh, Weight 45g, Storage Temperature -20℃~45℃, and Cycle

Battery Pack Thermal Modeling, Simulation and Electric

Aug 1, 2025 · In this paper, an electrochemical-thermal battery pack of three parallel-connected cylindrical Li-ion cells is modelled using COMSOL Multiphysics software. To investigate the

Development perspectives for lithium-ion battery cell

Dec 5, 2022 · As one central result, the market has witnessed a wide variety of manufacturer- and user-specific cell formats in the past. Standard formats for cylindrical cells were established

What Type of Battery Does My Huawei Phone Use?

Apr 11, 2025 · Huawei phones primarily use lithium-ion (Li-ion) or lithium-polymer (Li-Po) batteries, depending on the model. These batteries are chosen for their high energy density,

Thermal Modeling of a Cylindrical Lithium-Ion Battery in

Oct 28, 2021 · This example simulates an air-cooled cylindrical 18650 lithium-ion battery during a charge-discharge cycle, followed by a relaxing period. A lumped battery model is used to

Batteries & Fuel Cells Module Model Library

Dec 11, 2013 · Introduction This model example simulates an air-cooled cylindrical 18650 lithium-ion battery in 3D. The model follows the same approach as the model example Thermal

Improved equivalent circuit coupled 3D thermal cylindrical lithium

Jun 15, 2024 · This study introduces an improved equivalent circuit coupled 3D thermal model, the Multi-Partition Heat Generation and Thermal Resistance (MPH-TR) Model, developed for

Prismatic vs Pouch vs Cylindrical Lithium Ion

Jan 31, 2024 · In this article, we delve into the world of prismatic, pouch, and cylindrical lithium-ion battery cells, comparing their structures, advantages,

Complete List of Cylindrical Lithium Battery Models.

Cylindrical lithium-ion batteries are usually represented by five digits. Starting from the left, the first and second digits refer to the battery diameter, the third and fourth digits refer to the battery

Battery Design Module Application Library

Dec 13, 2022 · Introduction This example simulates an air-cooled cylindrical 18,650 lithium-ion battery in 3D. A one-dimensional cell model is used to model the battery cell chemistry, and a

Cylindrical lithium battery classification and

May 17, 2023 · Cylindrical lithium batteries are divided into different systems of lithium iron phosphate,lithium cobaltate,lithium manganate,cobalt-manganese

Huawei''s all-solid-state battery patent is

Jun 17, 2025 · The current ternary lithium battery actually has an energy density of only half of that of the all-solid-state battery, so theoretically, under the

The Clay-like Mechanics Model of Cylindrical Lithium-Ion Battery

Jun 1, 2016 · In this investigation, it was found that the mechanics characteristic of cylindrical lithium-ion battery is clay-like and the plastic constitutive equation of cylindrical lithium-ion

Analysis of Cylindrical Lithium Battery Advantages and Common Models

Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical cylindrical battery includes: casing, cap,

A universal anisotropic model for a lithium‐ion cylindrical cell

Mar 13, 2022 · Finite element models were developed for lithium-ion batteries. Two jellyroll materials were calibrated and compared, one isotropic and one anisotropic crushable foam

Analysis of Cylindrical Lithium Battery Advantages and Common Models

1. Definition of cylindrical lithium battery Cylindrical lithium battery is a kind of lithium ion battery, its shape is cylindrical, so it is called cylindrical lithium battery. The structure of a typical

A comprehensive equivalent circuit model for lithium-ion batteries

Nov 1, 2021 · The equivalent circuit model (ECM) is a battery model often used in the battery management system (BMS) to monitor and control lithium-ion batteries (

6 FAQs about [Huawei cylindrical lithium battery model]

What is Huawei's new lithium-ion battery technology?

Read more Back in 2019, Huawei filed a patent registration for its new method with the innovation name “a hard carbon anode material, lithium-ion battery and its preparation method and application.

Will Huawei patent a lithium-ion battery with graphene material?

Previously, Huawei also patented for lithium-ion battery with graphene material that could increase durability and performance. However, there’s no confirmation when and what Huawei is planning with these patents. Read more

How do you model a cylindrical lithium-ion battery?

For the modeling of cylindrical lithium-ion batteries, detailed structural models including cathode material, cathode material, diaphragms, and shells can more accurately react to battery deformation and faults, and determine the failure position, but usually require significant computational costs and the model is particularly complex.

What is a lithium ion battery?

The lithium-ion battery prepared as a negative electrode material has the high first reversible capacity, high first coulombic efficiency, stable properties, and consistent batches Good sex. Previously, Huawei also patented for lithium-ion battery with graphene material that could increase durability and performance.

Is there a homogenization model for lithium ion batteries?

At present, there have been many breakthroughs in the research of homogenization models. Xia et al. and Wang et al. respectively established a homogenization model of the cylindrical lithium-ion battery, considering the material as anisotropy and the influence of SOC and dynamic effect.

Are cylindrical lithium-ion batteries safe?

Abstract In engineering applications such as electric vehicles and energy storage systems, the structural safety of cylindrical lithium-ion batteries is crucial, especially under external impact or compressive loads that may induce deformation or damage, affecting overall safety performance.

Update Information

- Large cylindrical lithium battery model

- Azerbaijan cylindrical lithium battery model

- Andorra City cylindrical lithium battery model

- Praia lithium battery large cylindrical manufacturer

- Lg large cylindrical lithium battery

- 60300 cylindrical lithium battery

- Huawei Lithium Battery Pack Set

- Cylindrical lithium battery and square

- Honiara 10AH cylindrical lithium battery

- BAK cylindrical lithium battery

- 7cm cylindrical lithium battery

- Cylindrical lithium battery sales in Costa Rica

- Cylindrical lithium battery waterproof

Solar Storage Container Market Growth

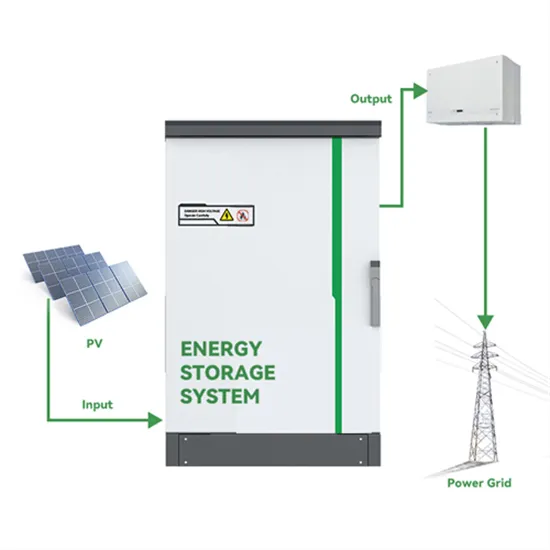

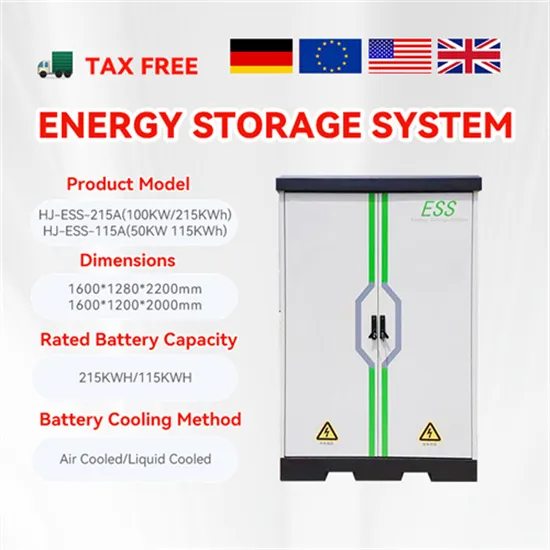

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.