The Future of Aluminum in Battery Technology:

Oct 26, 2024 · Explore the future of aluminum in battery technology, enhancing efficiency and longevity for electric vehicles and portable electronics. Discover

Energy Storage,Aluminium Profile Energy Storage,Aluminium Energy

The advantages of Aluminum Product mainly include lightweight, good thermal conductivity, corrosion resistance, processability, plasticity, and environmental friendliness. 1. Lightweight:

What are the new energy storage aluminum materials

Can aluminum be used as energy storage? Extremely important is also the exploitation of aluminum as energy storage and carrier medium directly in primary batteries, which would

Aluminum Alloy Series: Types, Properties, and Uses

Aug 8, 2024 · Learn about the different types of aluminum and alloys, their unique properties, and their applications in various industries. Boost your knowledge

What types of energy storage aluminum products are there?

Apr 17, 2024 · Aluminum-based energy storage solutions encompass a range of products, primarily including aluminum-air batteries, aluminum electrolytic capacitors, and lithium

application areas of energy storage aluminum profiles

The Journal of Energy Storage focusses on all aspects of energy storage, in particular systems integration, electric grid integration, modelling and analysis, novel energy storage

Different Types of Aluminum Grades & Their

6 days ago · There are many different types of aluminum. In total, there are seven different base alloy combinations exist for industrial use. These range in a

What are the brands of energy storage aluminum products?

Jan 4, 2024 · In the context of energy storage, these aluminum products are integral components—such as battery casings, heat sinks, and conductive materials—that enhance

Aluminum batteries: Unique potentials and addressing key

Jun 15, 2024 · Al batteries, with their high volumetric and competitive gravimetric capacity, stand out for rechargeable energy storage, relying on a trivalent charge carrier. Aluminum''s

Application and development of alloy materials in energy storage

Aluminum silicon alloy phase change materials have good density, thermal conductivity, and thermal stability. There is great research value and application potential in energy storage and

1501.01 History and Present State of Aluminium

Feb 27, 2020 · The alloys are: 99.5% pure aluminium (1050A) in the fully annealed state, suitable for deep pressing; a 4.5% magnesium-aluminium alloy (5083) after strain-hardening, by rolling,

Aluminum batteries: Unique potentials and addressing key

Jun 15, 2024 · These advantages include the abundance of aluminum, its superior charge storage capacity using Al3+ ions in comparison to Li ions, and a fourfold greater volumetric capacity for

Why Aluminum Alloy is Revolutionizing Energy Storage

Enter aluminum alloy for energy storage battery boxes, the unsung hero quietly transforming how we store solar and wind energy. The global energy storage market, valued at $33 billion [2],

Energy storage aluminum alloy die-casting housing

In general,the application of die-casting aluminum alloy in battery housing can be low-pressure casting or high pressure die casting. According to different requirements,it can also integrate

A review on metal hydride materials for hydrogen storage

Nov 20, 2023 · A storage technology with potential for different applications is hydrogen storage via absorption in metal hydrides. This technology offers high volumetric energy densities and

What are the applications of energy storage aluminum profiles

Aluminum profiles have become an indispensable component in a variety of industries, from aerospace to architecture. In this blog post, we will explore the types of aluminum profiles

Review of common hydrogen storage tanks and current

Mar 1, 2024 · There are a variety of aluminium alloys with different properties ranging from AA1XXX series to AA9XXX series according to different alloy compositions [76], while

What Are Aluminum Ingots, Types, Price And Applications?

The surface of an aluminum ingot is smooth and may have markings or identification symbols, such as the manufacturer''s logo or specific alloy information. Aluminum ingots serve as a

6 FAQs about [What types of energy storage aluminum alloy products are there]

Can aluminum be used as energy storage?

Extremely important is also the exploitation of aluminum as energy storage and carrier medium directly in primary batteries, which would result in even higher energy efficiencies. In addition, the stored metal could be integrated in district heating and cooling, using, e.g., water–ammonia heat pumps.

Can aluminum ion batteries revolutionize energy storage?

Aluminum is also a critical component in other low carbon technologies including wind, energy storage and hydroelectricity. The metal is used widely in both on-shore and off-shore wind projects, including tower platform components and turbines. And aluminum-ion batteries have the potential to revolutionize energy storage systems.

Can aluminum be used as energy storage and carrier medium?

To this regard, this study focuses on the use of aluminum as energy storage and carrier medium, offering high volumetric energy density (23.5 kWh L −1), ease to transport and stock (e.g., as ingots), and is neither toxic nor dangerous when stored. In addition, mature production and recycling technologies exist for aluminum.

Can aluminum batteries be used as rechargeable energy storage?

Secondly, the potential of aluminum (Al) batteries as rechargeable energy storage is underscored by their notable volumetric capacity attributed to its high density (2.7 g cm −3 at 25 °C) and its capacity to exchange three electrons, surpasses that of Li, Na, K, Mg, Ca, and Zn.

Is aluminum a good ESCM?

Aluminum appears to be a rather interesting ESCM, promising better performance and higher safety than hydrogen 5, 26 for large scale, global multisectoral energy storage. P2X applications would be favored by the high volumetric energy density of aluminum enabling rather easy and low-cost mid- and long-term storage.

What are aluminum ion batteries?

Aluminum-ion batteries (AIB) AlB represent a promising class of electrochemical energy storage systems, sharing similarities with other battery types in their fundamental structure. Like conventional batteries, Al-ion batteries comprise three essential components: the anode, electrolyte, and cathode.

Update Information

- What types of energy storage products are there

- What types of energy storage products are there in Belgrade

- What are the types of power station energy storage batteries

- What are the types of mobile energy storage power supplies

- What are the uses of home energy storage system products

- What types of energy storage battery backlights are there

- Botswana Aluminum Alloy Energy Saving Storage Equipment Quote

- What types of energy storage containers are there

- What is the price of the portable energy storage box in Asuncion

- What is the new electrochemical energy storage

- What is the Ngerulmud EK energy storage battery

- What is the voltage of a general energy storage battery

- What is the prospect of Chile s energy storage battery field

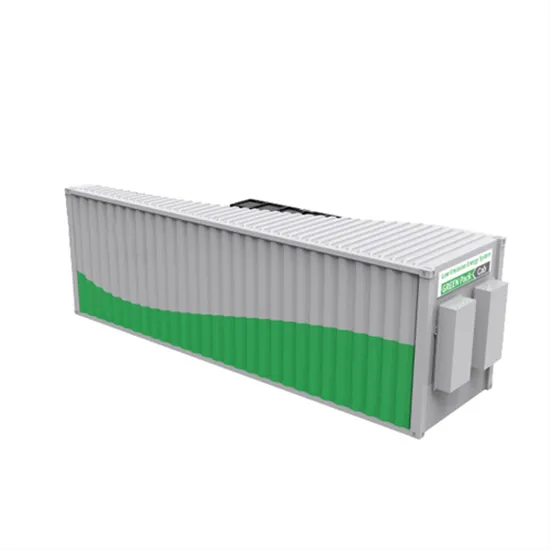

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.