Battcon 2009 Abstract

Jul 26, 2019 · First demonstrated by Gaston Planté in 1860, the venerable lead-acid battery is still the mainstay of energy storage. Over the years there have been many evolutions in the

Material Composition and Grid Structures in Lead-Acid Battery

Jan 10, 2025 · In energy storage batteries, grids are designed to be thicker and more robust to withstand the stresses of repeated deep discharges. Antimony-lead alloys are commonly used

Lead–acid battery energy-storage systems for electricity

Nov 30, 2001 · This paper examines the development of lead–acid battery energy-storage systems (BESSs) for utility applications in terms of their design, purpose, benefits and

Antimony-based liquid metal batteries the future of energy storage?

Aug 14, 2023 · Furthermore, antimony serves to reinforce the lead alloy plates within lead-acid batteries and is a fundamental component of flame retardants, enhancing their fire-resistant

Separation of antimony from lead-antimony alloy by molten

Oct 15, 2022 · Lead-acid batteries (LABs) are widely used in electric motorcycles, uninterruptible power systems, and stationary energy storage devices. However, spent LABs should be

Lead-acid batteries with low antimony alloys

Dec 1, 1976 · The better grid quality combined with the low antimony content improves the corrosion resistance especially when long time overcharge is applied, and as a result the

The rôle of antimony in the lead-acid battery: Part 1. The

Linear sweep voltammetric (LSV) and impedance studies of lead/antimony binary alloys (0–12% Sb) are described. The formation of a solid antimony-containing species in close contact with a

Advanced Industrial Lead-Acid Batteries

Abstract Depending on the application field, industrial storage can be classified into two main groups: material handling and reserve or stationary power. The present chapter outlines the

Past, present, and future of lead–acid batteries

Aug 21, 2020 · In principle, lead–acid rechargeable batteries are relatively simple energy storage devices based on the lead electrodes that operate in aqueous

Antimony: A Critical Metal for Defense and Industry, and

Feb 27, 2025 · Batteries: Antimony is a critical ingredient in lead-acid batteries, enhancing their longevity and performance. Semiconductors: Used in the production of diodes and infrared

Lead batteries for utility energy storage: A review

Feb 1, 2018 · Lead is the most efficiently recycled commodity metal and lead batteries are the only battery energy storage system that is almost completely recycled, with over 99% of lead

Antimony calcium battery energy storage

A high-temperature magnesium-antimony liquid metal battery comprising a negative electrode of Mg, a molten salt electrolyte, and a positive electrode of Sb is proposed and characterized and

Antimony Energy Storage Battery: The Future of Sustainable

Dec 19, 2020 · Why Antimony Batteries Are Stealing the Spotlight a battery that combines the energy density of lithium-ion, the affordability of lead-acid, and a dash of antimony magic.

Lithium–antimony–lead liquid metal battery for grid-level energy storage

Sep 21, 2014 · Here we describe a lithium–antimony–lead liquid metal battery that potentially meets the performance specifications for stationary energy storage applications.

Energy Storage with Lead–Acid Batteries

Jan 1, 2015 · The main components of a lead–acid cell are lead dioxide at the positive electrode and sponge lead on the negative, each in contact with a current-collector made from lead

Past, present, and future of lead–acid batteries

Aug 1, 2021 · of energy storage technologies. j Despite perceived competition between lead–acid and LIB tech-nologies based on energy density metrics that favor LIB in por-table applications

A SHARES ENERGY STORAGE BATTERY ANTIMONY

A high-temperature magnesium-antimony liquid metal battery comprising a negative electrode of Mg, a molten salt electrolyte, and a positive electrode of Sb is proposed and characterized and

Grid-Scale Energy Storage with Lead-Acid Batteries

This article delves into the role of lead-acid batteries in grid-scale energy storage, exploring their advantages, current applications, and the challenges they face in competing with more

Effects of micro-alloying with lead for battery grid material

Nov 15, 2022 · Alloying with Sn or Al in lead‑calcium grids produces even better lead acid batteries since Sn and Al improve castability, mechanical properties, and electrochemical

Removing antimony from waste lead storage batteries alloy

Apr 5, 2018 · With the wide application of lead acid battery, spent lead acid battery has become a serious problem to environmental protection and human health. Tho

Lead-Acid Battery : Components, Reactions & Charging

Discover the science behind lead-acid batteries! Learn about their components, chemical reactions, rechargeable nature, and applications in vehicles & power systems.

Battcon 2009 Abstract

Jan 11, 2023 · The attempt to paint lead-selenium with the same brush as lead-antimony makes sense in marketing space. The majority of all batteries sold are for standby service. Since lead

Antimony may be a renewable energy hero

Sep 9, 2021 · An unsung war hero that saved countless American troops during World War II, an overlooked battery material that has played a pivotal role in storing electricity for more than

Antimony liquid metal batteries – US challenger

Nov 10, 2022 · By 2023, liquid metal batteries (LMBs) are likely to be competing with Li-ion, lead-acid and vanadium flow batteries for long duration stationery

6 FAQs about [Antimony lead-acid batteries are the main energy storage]

Are lithium-antimony-lead batteries suitable for stationary energy storage applications?

However, the barrier to widespread adoption of batteries is their high cost. Here we describe a lithium–antimony–lead liquid metal battery that potentially meets the performance specifications for stationary energy storage applications.

Are lead-acid batteries a good choice for energy storage?

Lead–acid batteries have been used for energy storage in utility applications for many years but it has only been in recent years that the demand for battery energy storage has increased.

What are lead-acid rechargeable batteries?

In principle, lead–acid rechargeable batteries are relatively simple energy storage devices based on the lead electrodes that operate in aqueous electrolytes with sulfuric acid, while the details of the charging and discharging processes are complex and pose a number of challenges to efforts to improve their performance.

Are lead batteries sustainable?

Improvements to lead battery technology have increased cycle life both in deep and shallow cycle applications. Li-ion and other battery types used for energy storage will be discussed to show that lead batteries are technically and economically effective. The sustainability of lead batteries is superior to other battery types.

Why is electrochemical energy storage in batteries attractive?

Electrochemical energy storage in batteries is attractive because it is compact, easy to deploy, economical and provides virtually instant response both to input from the battery and output from the network to the battery.

Why is antimony a good battery?

Antimony’s cycling ability is its greatest strength. The reason to include VRLA here is that one of the fundamental issues with VRLA life is depolarization of the negative plate on long term charge. If the battery is being cycled, then the negative will not become depolarized which removes this failure mechanism.

Update Information

- Energy storage lead-acid batteries and lithium iron phosphate

- What are the main materials of energy storage batteries

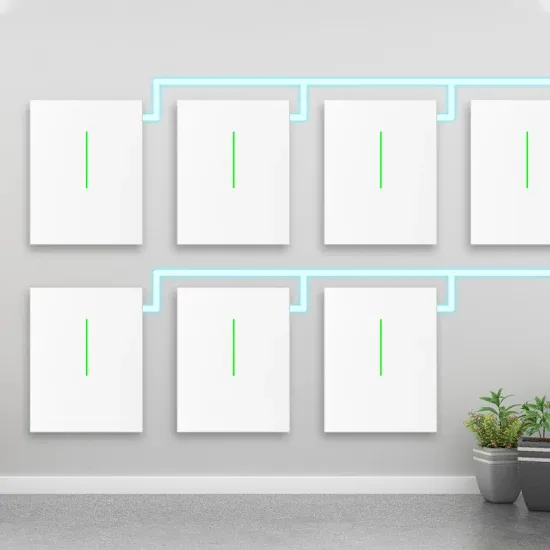

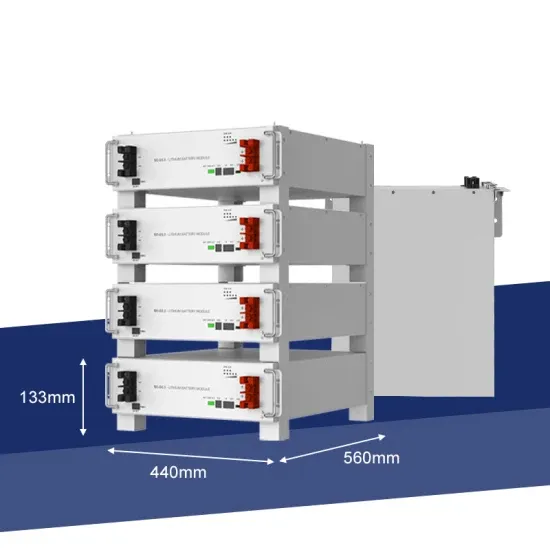

- Stacking Energy Storage Batteries

- Saudi Arabia s energy storage batteries are charged at night and used throughout the day

- The prospects of energy storage batteries

- Energy storage batteries can be outside

- Lithium batteries and gel batteries for energy storage

- Online shopping for energy storage cabinet batteries

- South America Energy Storage Batteries

- Hungarian household energy storage batteries

- The main components of Huawei Kiribati photovoltaic energy storage are

- Male entrepreneur who makes energy storage batteries

- Advantages and disadvantages of air-cooled batteries for energy storage

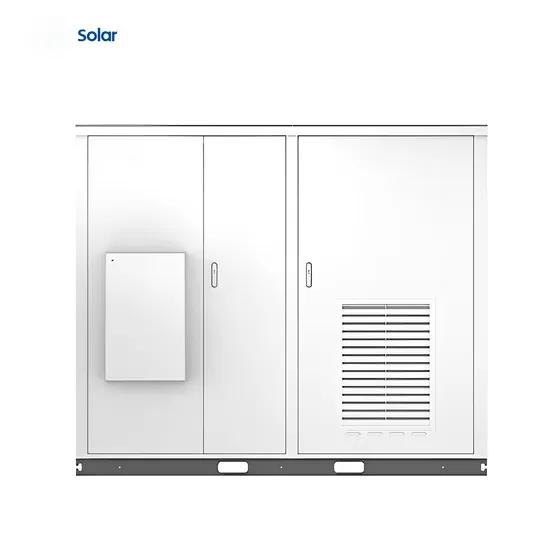

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.