Advancements in energy storage: a review of batteries and

Aug 9, 2025 · Energy storage technologies are fundamental to overcoming global energy challenges, particularly with the increasing demand for clean and efficient power solutions.

Battery | Composition, Types, & Uses | Britannica

Aug 6, 2025 · battery, in electricity and electrochemistry, any of a class of devices that convert chemical energy directly into electrical energy. Although the term

A review of battery energy storage systems and advanced battery

May 1, 2024 · Lithium batteries are becoming increasingly important in the electrical energy storage industry as a result of their high specific energy and energy density. The literature

What Are the Raw Materials Used in Lithium-Ion Batteries?

Apr 23, 2025 · What Are the Key Raw Materials for Lithium-Ion Batteries? The main raw materials used in lithium-ion batteries include: Lithium: The core component that provides energy

Understanding Battery Types, Components and

May 30, 2024 · Batteries have become an integral part of our everyday lives. In this article, we will consider the main types of batteries, battery components

What Materials Are In A Solid State Battery And Their Impact

Nov 7, 2024 · Solid state batteries utilize solid electrolytes instead of liquid ones. Common materials include lithium phosphorous oxynitride (LiPON) and sulfide-based electrolytes.

Energy Storage Materials: Types, Trends, and Real-World

Jan 21, 2025 · These materials convert and store energy through physical, chemical, or electrochemical processes, acting as the backbone of modern tech from iPhones to industrial

What Are the Essential Raw Materials for Lithium

May 3, 2025 · Lithium-ion batteries rely on materials like lithium, cobalt, nickel, graphite, and manganese for energy storage, stability, and performance in

What Element Is Used in Batteries? The Shocking

Jan 15, 2025 · Advancements in battery materials are transforming the landscape of energy storage, making it essential for you to stay informed about these

Energy Storage Materials — Types, Properties,

Jun 13, 2025 · Energy storage materials help store and release energy in systems like batteries. Lithium-ion and lithium iron phosphate batteries use some of the

Battery technologies: exploring different types of batteries for energy

Jan 5, 2024 · This comprehensive article examines and compares various types of batteries used for energy storage, such as lithium-ion batteries, lead-acid batteries, flow batteries, and

Different Types of Battery Energy Storage Systems (BESS)

Jan 14, 2025 · Conclusion Battery Energy Storage Systems (BESS) are crucial for improving energy efficiency, enhancing the integration of renewable energy, and contributing to a more

What are the main materials used in solid-state

Oct 31, 2024 · The main materials used in solid-state batteries can be divided into the cathode, anode, and solid electrolyte components. Each plays a critical

6 FAQs about [What are the main materials of energy storage batteries ]

What materials are used in a solid state battery?

Cathodes in solid state batteries often utilize lithium cobalt oxide (LCO), lithium iron phosphate (LFP), or nickel manganese cobalt (NMC) compounds. Each material presents unique benefits. For example, LCO provides high energy density, while LFP offers excellent safety and stability.

What are battery materials?

Please consider upgrading to a modern browser for better security and an improved browsing experience. Battery materials are the components that make up a battery, each serving a specific role in storing and harnessing electrical energy. The most well-known components are the electrodes (cathode and anode).

What are materials for chemical and electrochemical energy storage?

Materials for chemical and electrochemical energy storage are key for a diverse range of applications, including batteries, hydrogen storage, sunlight conversion into fuels, and thermal energy storage.

What are the different types of energy storage materials?

There are different types of energy storage materials depending on their applications: 1. Active materials for energy storage that require a certain structural and chemical flexibility, for instance, as intercalation compounds for hydrogen storage or as cathode materials. 2.

What makes a battery a good power source?

Continue exploring to uncover the science and future trends shaping our power sources. Batteries commonly utilize materials like aluminum, sulfur, sodium, and lignin for effective energy storage and performance. Lithium-ion batteries rely on metals like nickel and cobalt for energy density, though ethical sourcing concerns exist.

What is an example of a solid state battery?

They offer high stability and operate at various temperatures. Examples include lithium phosphorus oxynitride (LiPON) and garnet-type ceramics. Anodes in solid state batteries often use materials like lithium metal or silicon. These materials increase energy density and improve overall performance.

Update Information

- What is the difference between energy storage cells and batteries

- What are the large-capacity energy storage batteries in Germany

- What are the types of chemical energy storage batteries

- Antimony lead-acid batteries are the main energy storage

- Main application scenarios of energy storage batteries

- What batteries are used in energy storage battery containers

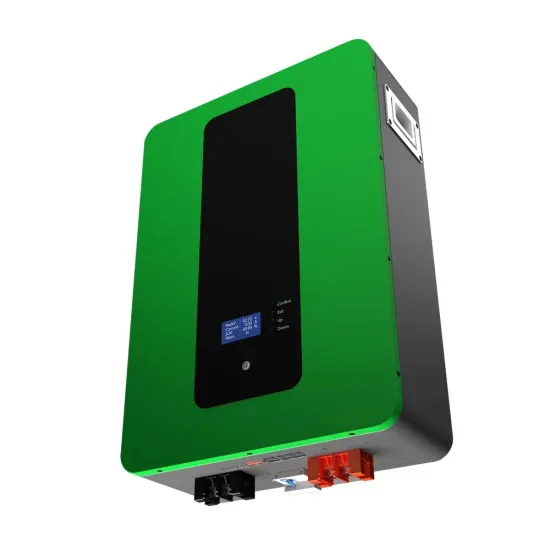

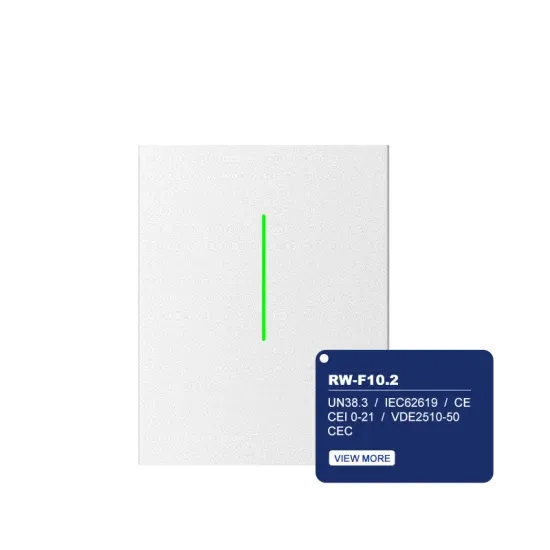

- What kind of batteries are generally used for household energy storage

- What energy storage batteries are used in battery swap stations

- What batteries are included in the photovoltaic energy storage battery cabinet

- What are the standards for energy storage batteries

- What does the energy storage power system include

- What does the energy storage communication system include

- What is the energy storage battery factory in Spain

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.