What are battery liquid-cooled energy storage devices?

Aug 17, 2024 · The exploration of battery liquid-cooled energy storage devices reveals profound implications for various industries and applications. These systems emphasize optimized

A review of air-cooling battery thermal management systems for electric

Jul 31, 2021 · Battery Thermal Management System (BTMS) is critical to the battery performance, which is important to the overall performance of the powertrain system of Electric Vehicles

Advantages of Liquid-Cooled Battery Energy Storage

Liquid-cooled battery energy storage systems provide better protection against thermal runawaythan air-cooled systems. "If you have a thermal runaway of a cell,you''ve got this

A review on the liquid cooling thermal management system

Dec 1, 2024 · Lithium-ion batteries (LIBs) are gradually becoming the choice of EVs battery, offering the advantages of high energy storage, high power handling capacity, and long life

Cooling Characteristics and Optimization of an Air-Cooled Battery

Jan 31, 2025 · The air-cooled battery thermal management system (BTMS) is a safe and cost-effective system to control the operating temperature of battery energy storage systems

A novel battery thermal management system with air–liquid

Jul 15, 2025 · Lithium-ion batteries (LIBs) have attracted worldwide attention as a key component of EVs. Compared to other power batteries such as lead-acid battery and nickel-metal hydride

Advantages and disadvantages of direct cooling

Apr 9, 2021 · Direct-cooled cold storage Advantages of direct cooling cold storage: 1. Direct cooling type cold storage has simple structure, relatively low

Air Cooling vs. Liquid Cooling of BESS: Which One Should

Aug 15, 2024 · Battery Energy Storage Systems (BESS) are essential for storing energy and ensuring its availability when needed. However, like all electronic systems, batteries generate

Comparison of advantages and disadvantages of various energy storage

Nov 16, 2023 · Comparison of advantages and disadvantages of various energy storage systems 1, mechanical energy storage Mechanical energy storage mainly includes pumped storage,

Air Cooling Battery Systems for Versatile and Scalable Energy Storage

Aug 11, 2025 · Air cooling battery systems provide a versatile and efficient solution for commercial, industrial, and off-grid energy storage applications. Offering a combination of cost

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Air Cooling or Liquid Cooling, Which is Suitable? Ultimately, the choice depends on scale and requirements. Air cooling remains viable for low

Battery Cooling Tech Explained: Liquid vs Air

May 9, 2025 · Advantages of air cooling include lower initial cost, simpler design, and minimal maintenance, thanks to no pump or liquid, simple fans or vents,

Advantages and disadvantages of air-cooled lithium

Air cooling is a common method used in lithium-ion batteries and has been widely studied and researched. 93-95 Air cooling modules are widely used in commercial electric vehicles due to

Comparison of cooling methods for lithium ion

Dec 13, 2023 · Comparison of cooling methods for lithium ion battery pack heat dissipation: air cooling vs. liquid cooling vs. phase change material cooling vs.

Air Cooling Battery Systems for Versatile and Scalable Energy Storage

Aug 11, 2025 · Explore the advantages of air cooling battery systems for energy storage. Ideal for commercial, industrial, and renewable energy applications where flexibility, cost

6 FAQs about [Advantages and disadvantages of air-cooled batteries for energy storage]

Can air cooling reduce the maximum temperature of lithium ion batteries?

Yu et al. developed a three-stack battery pack with the stagger-arranged Lithium-ion battery cells on each stack with two options: natural air cooling and forced air cooling as shown in Fig. 2. The experimental results showed that the active air cooling method could reduce the maximum temperature significantly. Fig. 2.

What are the disadvantages of air cooling?

Disadvantages of Air Cooling Limited Cooling Capacity: Air cooling may not be sufficient for high-capacity BESS or in environments with extreme temperatures. The efficiency of air cooling is directly affected by ambient temperature, which can limit its effectiveness.

Which cooling method is best for battery energy storage systems?

When it comes to managing the thermal regulation of Battery Energy Storage Systems (BESS), the debate often centers around two primary cooling methods: air cooling and liquid cooling. Each method has its own strengths and weaknesses, making the choice between the two a critical decision for anyone involved in energy storage solutions.

What is an air cooled battery system?

Air-cooled systems use ambient air flow – fans or natural convection – to carry heat away from the cells. They are simple and low-cost, since no coolant, plumbing or pumps are needed. Air cooling avoids leak hazards and extra weight of liquids. As a result, smaller or lower-power battery installations often rely on air-cooled designs.

Why is battery heat dissipation important?

Therefore, an effective battery heat dissipation system is important for improving the overall performance of the battery pack. At present, the common lithium ion battery pack heat dissipation methods are: air cooling, liquid cooling, phase change material cooling and hybrid cooling.

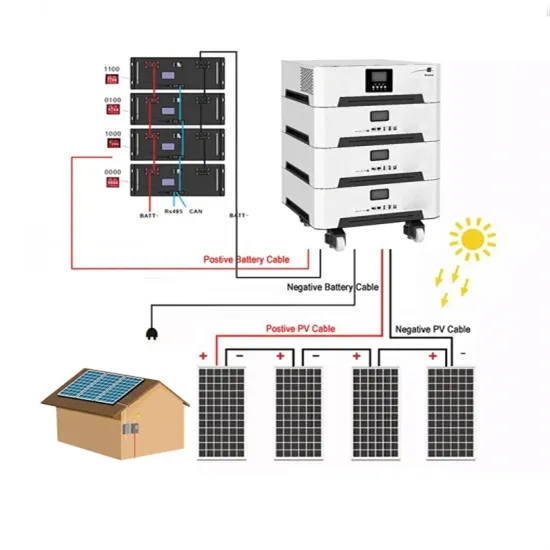

What is a battery energy storage system?

Battery Energy Storage Systems (BESS) are essential for storing energy and ensuring its availability when needed. However, like all electronic systems, batteries generate heat during operation, especially when discharging or charging at high rates. Effective cooling is crucial to maintain the efficiency, safety, and longevity of these systems.

Update Information

- Advantages and disadvantages of universal energy storage batteries

- Advantages and disadvantages of solar energy storage batteries

- Advantages and disadvantages of lead-zinc energy storage batteries

- Advantages and Disadvantages of Liquid Flow Energy Storage Batteries

- Advantages and disadvantages of perfluorinated energy storage batteries

- Advantages and disadvantages of ultra-large energy storage batteries

- Advantages and disadvantages of Huawei s energy storage battery

- Advantages and disadvantages of reverse energy storage power supply

- Advantages and disadvantages of energy storage products

- Advantages and disadvantages of lithium iron phosphate energy storage battery cabinet

- What are the advantages and disadvantages of large-capacity energy storage cabinets

- Advantages and disadvantages of air energy storage power generation

- 12V energy storage battery advantages and disadvantages

Solar Storage Container Market Growth

The global solar storage container market is experiencing explosive growth, with demand increasing by over 200% in the past two years. Pre-fabricated containerized solutions now account for approximately 35% of all new utility-scale storage deployments worldwide. North America leads with 40% market share, driven by streamlined permitting processes and tax incentives that reduce total project costs by 15-25%. Europe follows closely with 32% market share, where standardized container designs have cut installation timelines by 60% compared to traditional built-in-place systems. Asia-Pacific represents the fastest-growing region at 45% CAGR, with China's manufacturing scale reducing container prices by 18% annually. Emerging markets in Africa and Latin America are adopting mobile container solutions for rapid electrification, with typical payback periods of 3-5 years. Major projects now deploy clusters of 20+ containers creating storage farms with 100+MWh capacity at costs below $280/kWh.

Containerized System Innovations & Cost Benefits

Technological advancements are dramatically improving solar storage container performance while reducing costs. Next-generation thermal management systems maintain optimal operating temperatures with 40% less energy consumption, extending battery lifespan to 15+ years. Standardized plug-and-play designs have reduced installation costs from $80/kWh to $45/kWh since 2023. Smart integration features now allow multiple containers to operate as coordinated virtual power plants, increasing revenue potential by 25% through peak shaving and grid services. Safety innovations including multi-stage fire suppression and gas detection systems have reduced insurance premiums by 30% for container-based projects. New modular designs enable capacity expansion through simple container additions at just $210/kWh for incremental capacity. These innovations have improved ROI significantly, with commercial projects typically achieving payback in 4-7 years depending on local electricity rates and incentive programs. Recent pricing trends show 20ft containers (1-2MWh) starting at $350,000 and 40ft containers (3-6MWh) from $650,000, with volume discounts available for large orders.